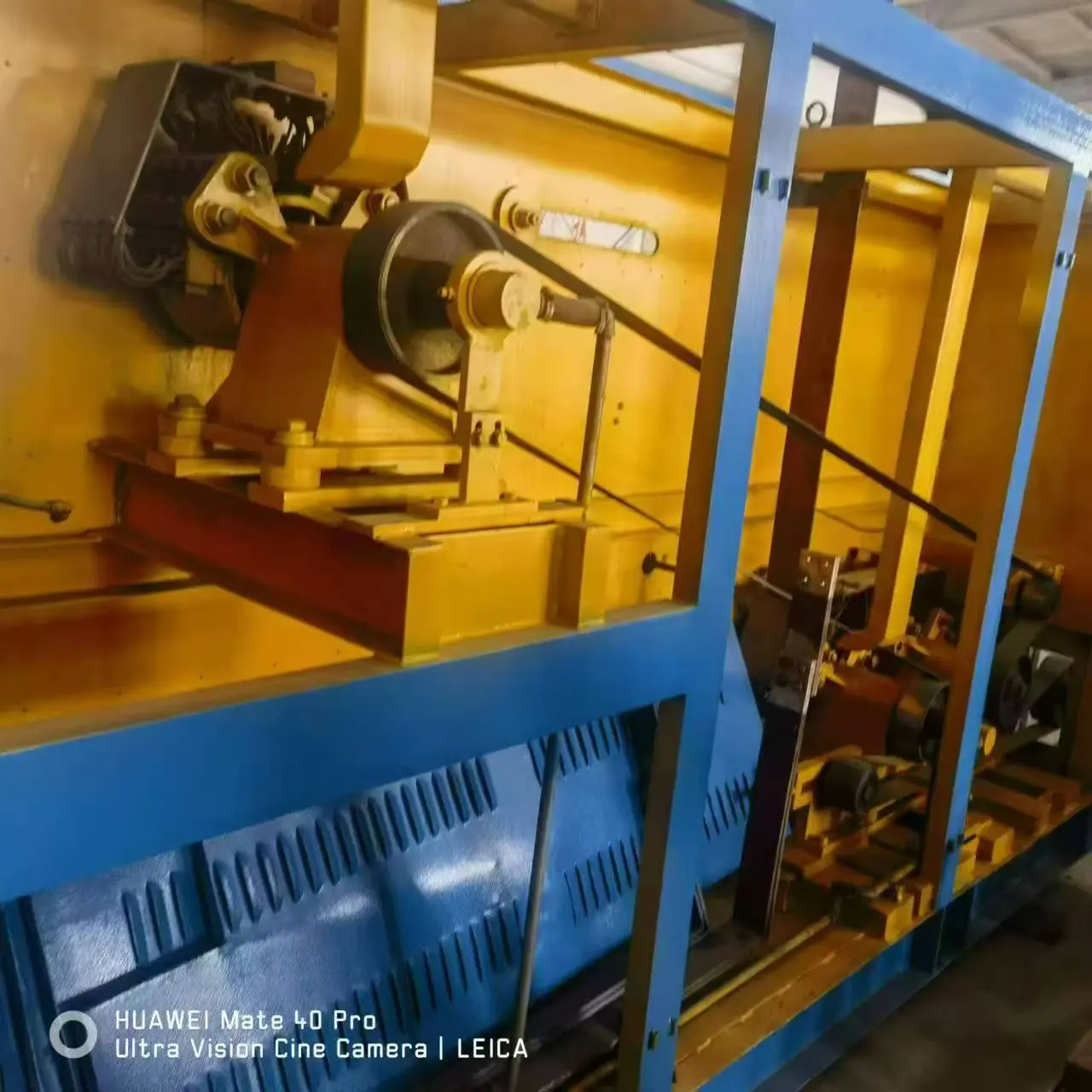

Used Copper Coarse Wire Drawing Machine DL450/9D, Feed Rod Diameter 8mm and Outlet Diameter 3mm

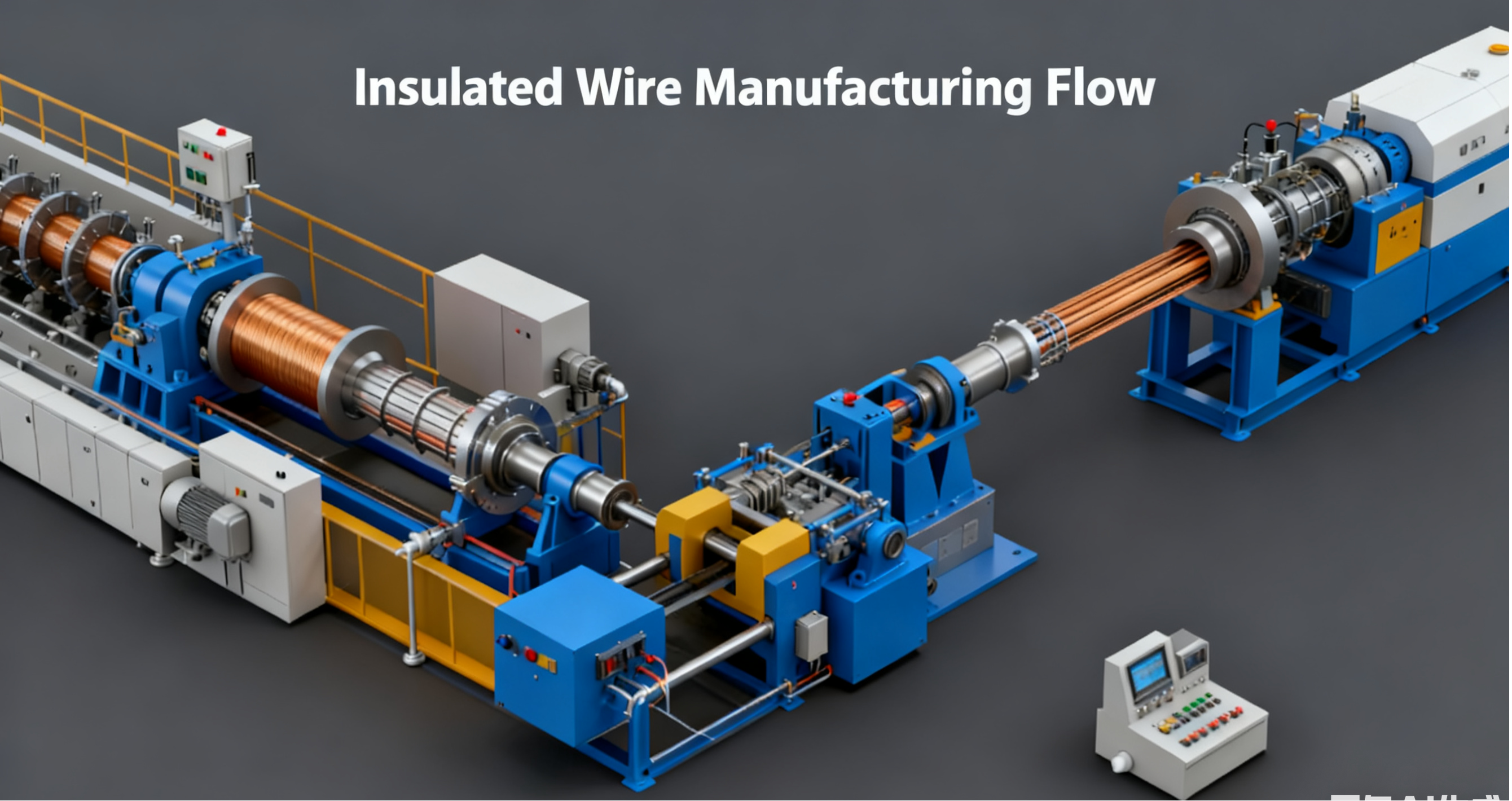

The professional term for drawing machine is also called thick wire drawing machine, which is used for the drawing and annealing of copper wire, aluminum wire, brass wire, and copper-magnesium alloy wire for high-speed rail contact wire. According to the diameter of the wire drawing drum, it is divided into 400 drawing machine (DL400), 450 drawing machine (DL450), and 500 drawing machine (DL500). According to the number of wire drawing dies, it is divided into 9-die drawing machine (DL400/9, DL450/9, DL500/9); 11-die drawing machine (DL400/11, DL450/11, DL500/11); 13-die drawing machine (DL400/13, DL450/13, DL500/13)

High-speed copper wire drawing machine is used to draw φ8.0mm copper wire into φ2.00mm-φ4.0mm copper wire. The wire drawing drums are arranged in a row, and each drum is independently driven by a reduction box, continuous drawing, balanced mechanical and electrical speed matching, easy operation, and coiled wire collection. This machine has the advantages of easy operation, high production efficiency, and good product quality.

1. Main technical parameters of the equipment

Inlet rod diameter: φ8.0mm

Outlet wire diameter: φ2.00mm-φ3.50 mm

Drawing speed: 1000m/min

Pulley diameter: φ450mm

Maximum drawing passes: 9 passes

Maximum length of wire storage: 7m

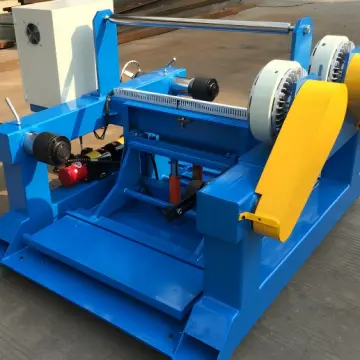

Wire take-up rack size: ф800×ф1000×1500 mm

Mechanical elongation coefficient: 1.278

Drawing oil lubrication: full immersion

Main engine motor power: 185kw ac, with variable frequency speed regulation

Plum blossom take-up motor power: 22kw ac, with variable frequency speed regulation

Maximum mold specification: φ43×35 (national standard)

Total installed capacity: 185kva

Unit dimensions (length×width×height): 16500mm×4500mm×4400mm

2. Main components of the equipment

This equipment consists of a wire pay-off stand, a rolling head threading machine, a wire drawing main machine, a wire drawing lubrication system and cooling system, a vertical tension wire storage device, a coiling wire taking-up device, an electrical control system, etc.

Equipment production speed and capacity:

|

TY,Hardwire |

||

|

Specification(mm) |

Line speed(m/min) |

Hourly output(kg/hr) |

|

2.60 |

700 |

1700 |

|

3.00 |

500 |

1600 |

|

3.50 |

400 |

1744 |

Guanbiao 450/9(module), 8 in and 3 out, Barrel type (plum blossom falling barrel) wires take-up machine