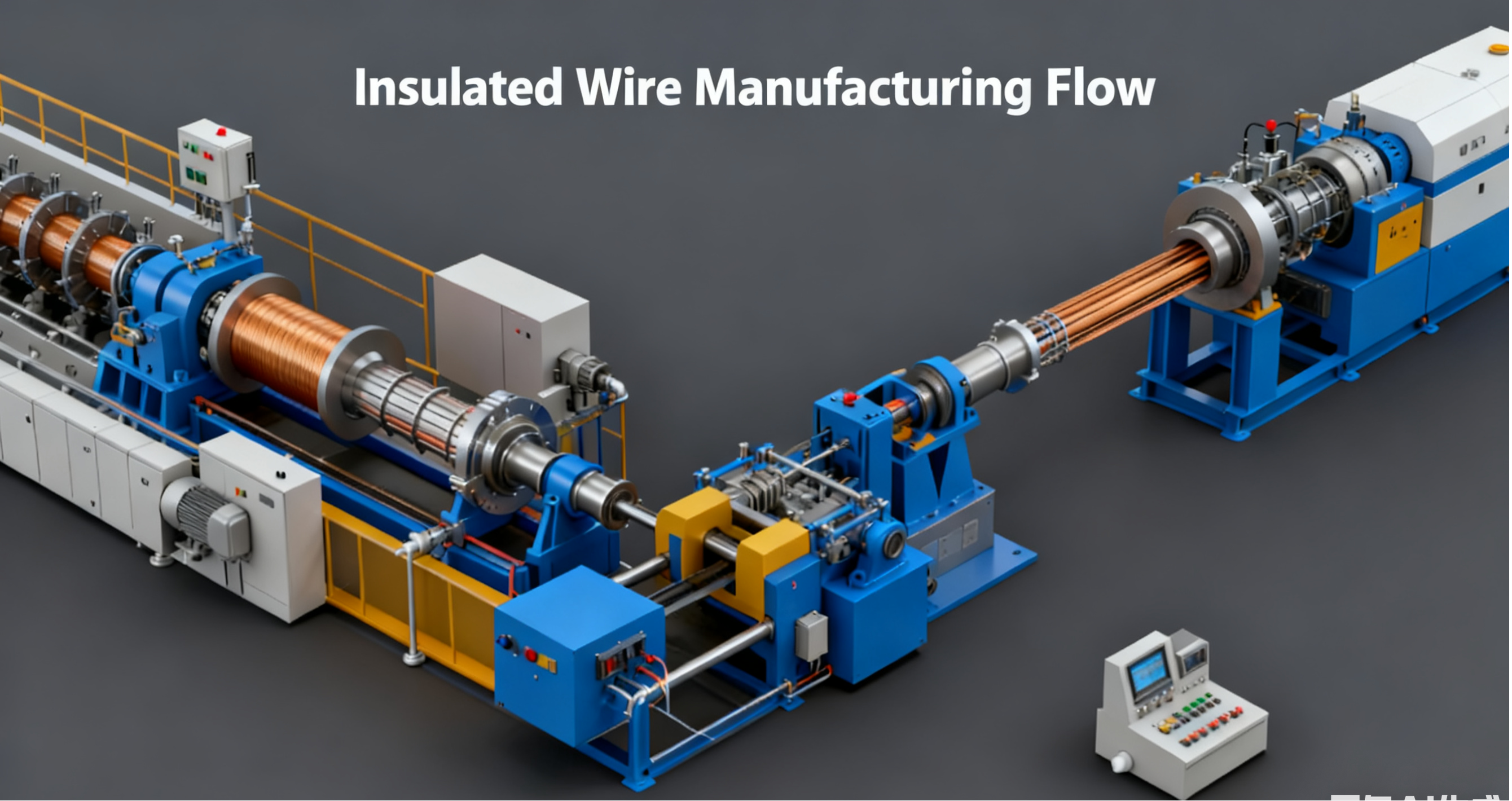

Technical Specification for Φ80+50 Double-Layer Insulation Co-Extrusion Production Line for Photovoltaic Cables

Main Configuration

| No. | Component Name | Model | Brand | Quantity | Function | Reference Image |

|---|---|---|---|---|---|---|

| 1 | Double-head Shaftless Magnetic Powder Pay-off Rack | Φ500-630mm | DOFINE | 1 unit | For passive pay-off of copper wires |  |

| 2 | Double-wheel Vertical Magnetic Powder Tension Frame | Φ300mm | DOFINE | 1 unit | Tension control for pay-off |  |

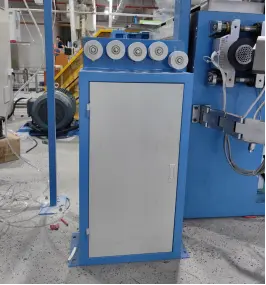

| 3 | Straightening Table | Φ60mm | DOFINE | 1 unit | Straightening of copper wires |  |

| 4 | High-output Extrusion Main Machine | Φ80x26D | DOFINE | 1 unit | Extrusion of PVC and PE materials |  |

| 5 | Adjustable Double-Layer Co-Extrusion Die Head | U14 | DOFINE | 1 piece | Wire shaping |  |

| 6 | 50 Horizontal Stripe Extruder | Φ50x26D | DOFINE | 1 unit | Double-layer co-extrusion |  |

| 7 | Hopper Dryer with Automatic Suction Feeder | 25KG | Ketianda | 1 set | Automatic feeding and drying of rubber materials for 50 main machine |  |

| 8 | Hopper Dryer with Automatic Suction Feeder | 100KG | Ketianda | 1 set | Automatic feeding and drying of rubber materials for 80 main machine |  |

| 9 | Electrical & Temperature Main Control Cabinet | PLC-type, combined cabinet | DOFINE | 1 set | Electrical control | (See Image: Extrusion Main Machine Electrical Cabinet, Dongguan Jingfeng Electric Machinery Co., Ltd., TEL: (0769) 89237298, Mobile: 13826906328) |

| 10 | 2m Parent-Child Movable Water Tank (with Blowing Drying Device) | 150x170mm | DOFINE | 1 set | Mobile cooling |  |

| 11 | Laser Diameter Gauge | 25AL3 | Shanghai Gongjiu | 1 unit | Wire diameter measurement and automatic control |  |

| 12 | 10m Single-Layer U-Type Cooling Water Tank | 150x170mm | DOFINE | 1 set | Wire cooling |  |

| 13 | Double-wheel Traction Machine | Φ600mm | DOFINE | 1 unit | Wire traction |  |

| 14 | 12m Horizontal Tension Wire Storage Rack | Φ350mm | DOFINE | 1 set | Wire storage |  |

| 15 | High-Speed Printing Machine | Φ100mm | DOFINE | 1 unit | Ink printing on wire surface |  |

| 16 | Power Frequency Spark Tester | 15KV | DOFINE | 1 unit | Detection of wire insulation defects |  |

| 17 | Electronic Inductive Length Counting Device | Φ159mm | DOFINE | 1 set | Length measurement |  |

| 18 | Φ630 Double-Shaft Take-up Machine | Φ630 | DOFINE | 1 unit | Wire take-up |  |

| 19 | Special Screw for Low-Smoke Halogen-Free Materials | Φ50x26D | DOFINE | 1 unit | Extrusion of low-smoke halogen-free materials for 50 main machine | - |

| 20 | Special Screw for Low-Smoke Halogen-Free Materials | Φ80x26D | DOFINE | 1 unit | Extrusion of low-smoke halogen-free materials for 80 main machine | - |

| 21 | Spare Parts | - | DOFINE | 1 set | Provided with the machine | - |

| 22 | Random Tools | - | DOFINE | 1 set | Provided with the machine | - |

| 23 | Random Documents |

- |

DOFINE | 1 set | Provided with the machine | - |

Equipment Description

Application

Suitable for producing thermoplastic plastics such as photovoltaic (PV) cables, cross-linked polyethylene (XLPE) cables, flexible polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), and low-smoke halogen-free materials.

Brands of Main Accessories

Main Specifications & Performance

Main Technical Parameters & Configuration

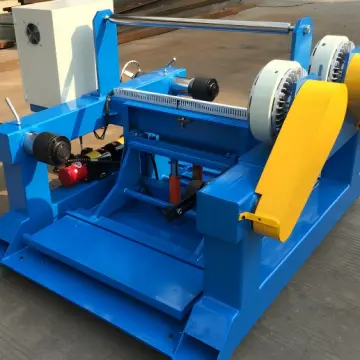

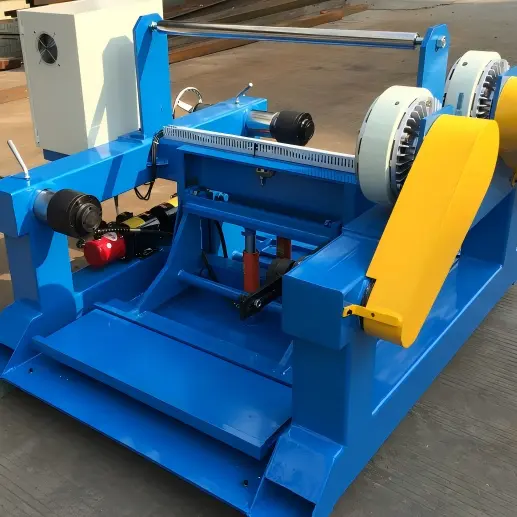

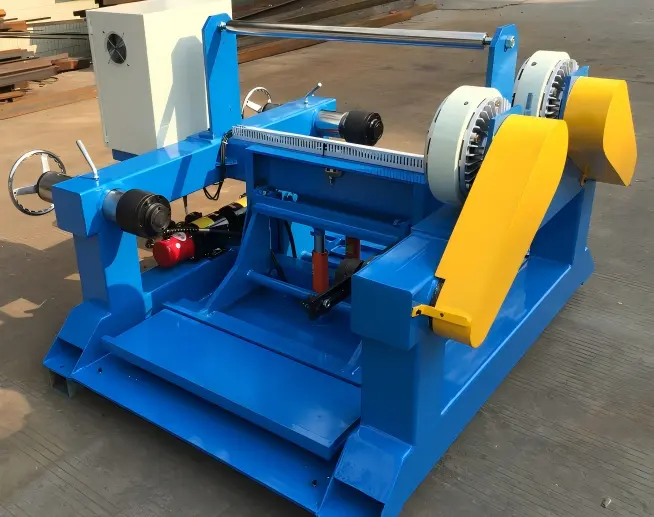

1. Φ500-630mm Double-Head Shaftless Magnetic Powder Pay-off Rack

1-2. Type: Double-head pay-off, shaftless pneumatic tightening, quick top cone for reel up and down1-3. Reel: Suitable for Φ500-630mm spools1-4. Applicable wire diameter: Φ0.4-5.0mm1-5. Tension range: 5KG magnetic powder clutch tension, manual electronic adjustment1-6. Maximum wire feeding speed: 400m/min1-7. Reel loading/unloading method: 1 unit of 2HP geared motor with lead screw lifting, limit switch for extreme protection1-8. Maximum load capacity: 3000kg

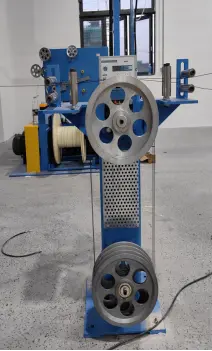

2. Vertical Magnetic Powder Tension Frame

2-2. Aluminum wheel: Diameter Φ300mm2-3. Magnetic powder clutch: 5kg, tension range 500~5000g (adjustable)2-4. Center height: 1000mm

3. Copper Wire Straightening Table (with Toolbox)

3-2. External structure: A3 steel plate welded assembly

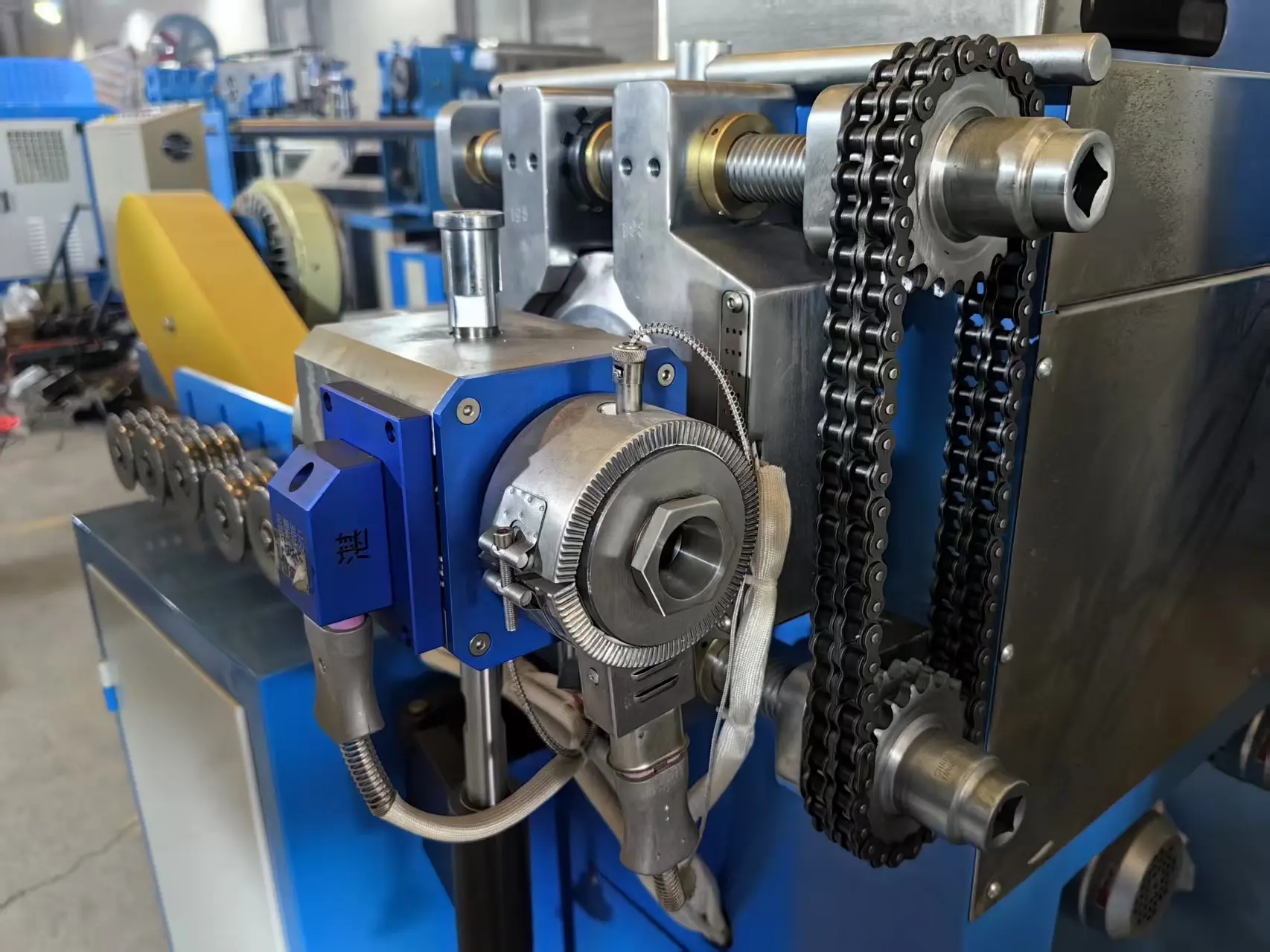

4. Φ80 Extrusion Main Machine

4-1. Frame: A3 steel plate and channel steel assembly

4-2. Gearbox: Model 225-16A. Gearbox: Square cast structure, annealed, material HT200~300B. Gear teeth: High-frequency quenched and precision ground, noise level <75dB, forced oil lubrication for gears

4-3. Screw: 1 piece of Φ80mm BM thread screw, length-diameter ratio 26:1, compression ratio 3.0:1; suitable for PE, PVC and other rubber materials, 100% plasticization; material 38CrMoAl, hardness HRC60~63 or above, nitriding depth HRC60~63, surface hard chrome plating; speed 5-100RPM; maximum extrusion capacity 300kg/h (die head open)

4-4. Barrel: Integral structure from gearbox connection to die head; material 38CrMoAl, hardness HRC60~63 or above, nitriding depth 0.4~0.7mm; 5 temperature measurement points; barrel wall temperature accuracy ±2℃; 5 units of high-pressure centrifugal fans (1 per barrel section)

4-5. Electric heating: 5 heating zones for screw, cast aluminum heaters, voltage AC380V 2kW per zone; controlled by PID intelligent temperature controller and contactor

4-6. Cooling: 5 units of 370W high-pressure centrifugal fans, automatically controlled by temperature controller

4-7. Main machine drive: AC380V 55kW AC motor with AC380V 55kW frequency converter

4-8. Die head: 1 adjustment-free die head with stripe injection (with 1 set of dies); 2 temperature control zones; die drawing dimensions provided; adjustable gap between inner and outer dies

4-9. Die head clamp:A. Type: Latch-type clamping, built-in stainless steel tube heaterB. Locking direction: Quick wrench locking (counterclockwise)

5. Hopper Dryer with Automatic Suction Feeder

5-2. Feeding dryer: Equipped with hot-air electric heater; barrel temperature and heating time can be set manually; electric heating (See Image) + air supply 90W5-3. Automatic feeder: Vacuum strong suction type; suction bucket placed above the machine; exhaust fan power ≥1.0HP; feeding height 4m

6. Electrical & Temperature Control (Electrical Components are Imported)

6-2. Control power switch (See Image) - 2 pieces6-3. Control power switch (AC380V 2P) - 11 pieces6-4. Control power switch - 1 piece6-5. Pointer-type total current/voltage meter - 2 pieces6-6. Electric heating temperature controller - 9 pieces6-7. Electric heating ammeter - 9 pieces6-8. Cooling fan control - 6 groups6-9. Speed meters for main machine and traction - 3 pieces in total6-10. Single-action/linkage control for main machine and traction - 1 group6-11. Indicator lights (all parts) and internal/external lights of control cabinet - 1 set6-12. Control cabinet ventilator - 2 pieces6-13. Tension control of tension frame and displacement detection control - 1 group6-14. Taiwan Weinview 10.4-inch color HMI - 1 set

HMI + PLC Control

7. 2m Parent-Child Movable Water Tank

7-2. External dimension: (See Images), moving range 0.5m7-3. Equipped with upper cover (sealed) and water wiper (blowing drying device) - 1 set; stainless steel bracket and bearing guide wheel (adjustable up, down, left and right)7-4. Blowing drying device:A. Structure: Two-stage flip-top type, material: plastic-steelB. Air pressure: Adjustable, with 1 set of switchesC. Noise reduction device

8. Laser Diameter Gauge

8-2. Accuracy: ±0.001mm8-3. Wire diameter range: 0.2-25mm8-4. Control: Automatically feeds back to control main machine speed to ensure wire diameter within set range

9. 10m U-Type Single-Layer Fixed Water Tank

9-2. Length: 10m (single-layer), 150mmx170mm

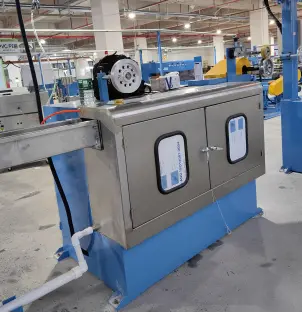

10. Enclosed Double-Wheel Traction Machine

10-2. Traction wheels: Material - aluminum alloy, diameter Φ600mm (2 wheels)10-3. Water tank: Stainless steel sealed water tank, with 1 set of windows and water wipers10-4. Drive: AC380V 4KW AC motor + (See Image) frequency converter, linkage control with main machine10-5. Line speed: 400m/min, linkage control with main machine

11. 12m Horizontal Tension Wire Storage Rack

11-2. Track: 125×125 I-steel, horizontal type (length 12m), with sliding plate11-3. Power: 3HP geared motor11-4. Tension: 20kg magnetic powder clutch11-5. Wire storage length: 10m~200m11-6. Wire storage wheel diameter: Φ300mm, material - aluminum alloy, number of wheels: 10+11, surface anodizing hardening11-7. Tension adjustment: Tension control box (DC-24V power supply) for arbitrary tension adjustment; trolley can be controlled forward/reverse; tension value displayed on meter; synchronizer automatically controls take-up speed to prevent wire from being stretched or broken11-8. Safety device: Limit switches at front and rear ends, synchronous stop control when wire breaks11-9. Anti-collision: Compression spring

12. 15KV Power Frequency Spark Tester

12-2. Outer diameter range: Φ0.3~Φ15mm12-3. Test voltage: 0.5~15kV, high-voltage frequency: 3000Hz12-4. Output indication: 5-digit LED spark counter12-5. Detection chamber length: 600mm12-6. Maximum current: 0.667mA12-7. Alarm output: LED alarm indication; optional linkage with take-up machine for automatic stop after alarm12-8. Complies with standards of Japan, the US, Europe, and China 3C certification

13. Electronic Length Counting Device

13-2. Length counting wheel: Grooves with ceramic spraying for wear resistance

14. High-Speed Printing Machine

14-2. Power: Single-phase 220V 25W (stirring); maximum printing speed 500m/min; printing quality meets requirements of UL, CSA, VDE, JIS, etc.14-3. Ink box: Stainless steel, 2 pieces provided with the machine14-4. Equipped with ink traction wheel; printing on cable surface after ink scraping device14-5. Center height: 1000mm

15. Φ630mm Double-Shaft Take-up Machine

15-2. Frame: Channel steel and A3 steel plate welded assembly15-3. Drive: 2 units of AC380V 5HP motors, equipped with AC380V 5HP frequency converters; automatic take-up control via tension frame displacement detector15-4. Length counting: 6-digit electronic length counting, with automatic stop function15-5. Cable arrangement: Polished rod bearing control for cable arrangement; adjustable arrangement pitch and width; neat arrangement; linkage with take-up speed

Random Accessories

A. Tools

B. Spare Parts

C. Random Documents

Note: Images are for reference only; the actual product shall be subject to this configuration and the design technology of our factory.