0102

Steel Wire or Steel pipe PVC Coating Line

description2

Steel pipe coating product introduction

Features of steel pipe coating equipment

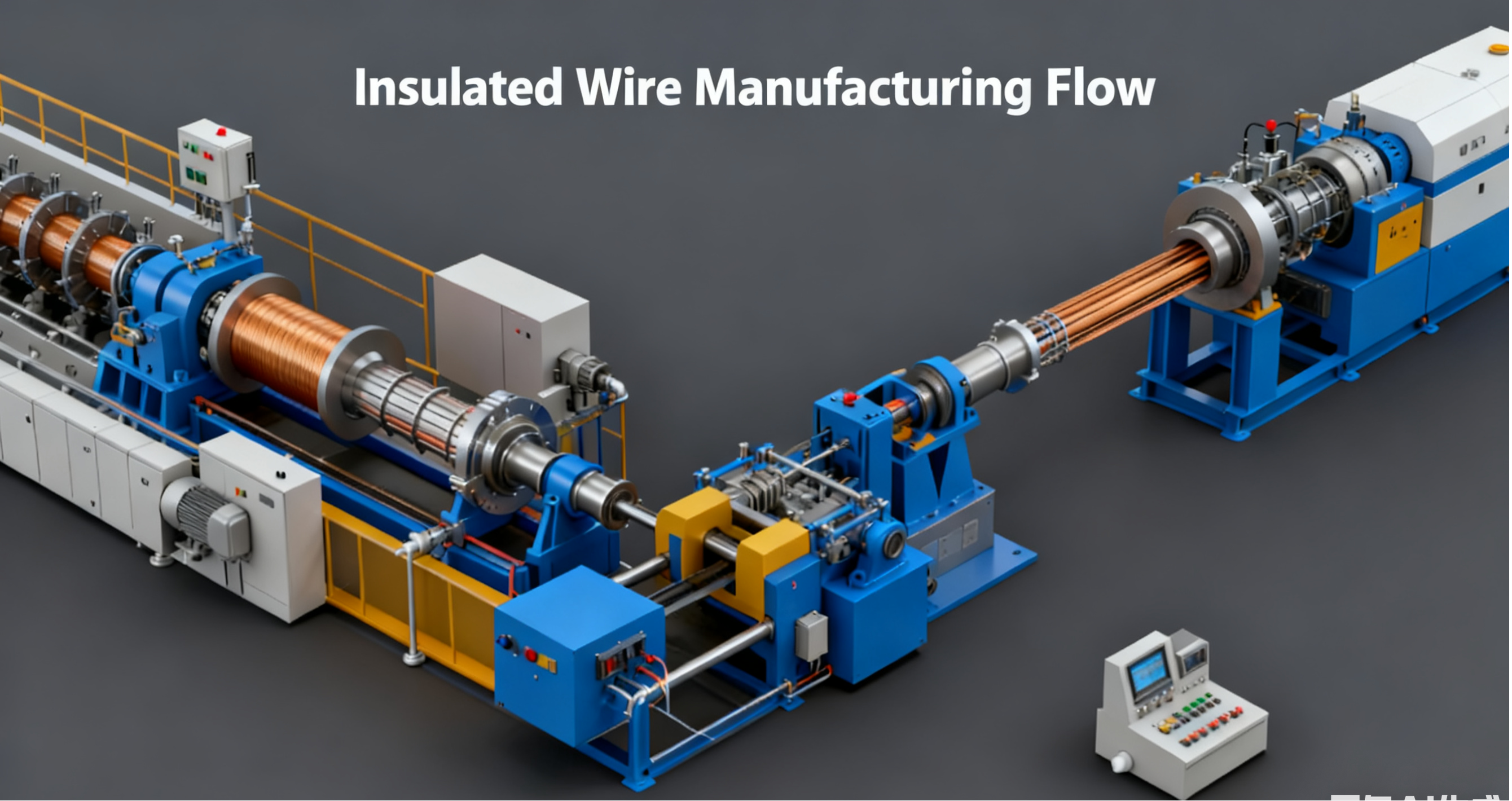

The production line consists of a steel pipe stacking conveyor or wire laying machine, a traction machine (one each in front and back), a high-frequency heating device, a right-angle coating mold, a single-screw extruder, a cooling device, etc. Each iron wire or steel pipe can be connected by a joint to achieve continuous coating extrusion production. The iron wire or pipe products produced are densely coated, the plastic layer is uniform in thickness, the size is stable, and the appearance is smooth

Wire Coating Detailed Description

Wire PVC coating line is used to produce PVC insulated wire, the customer can produce insulated wire of different size by change the machine head and related accessories. The extruder and tractor apply YCT series governor motor with big range of speed adjustment; we use the intelligent temperature control instrument to control the temperature of the capstan and head automatically with high sensitivity. The structure of the production line is simple, easy to operate, safe and reliable.

Wire coating is a critical step in the manufacturing process of wires that improves their performance and durability. The process involves applying an insulating layer around the wire, which can be made of a variety of materials such as PVC, polyethylene, or rubber. The coating serves a variety of purposes: preventing leakage, protecting the wire from environmental factors such as moisture and chemicals, and providing mechanical strength to the wire.

Depending on the wire type and intended use, different coating techniques are employed, such as extrusion and dipping. The thickness and type of coating can be tailored to specific requirements, ensuring optimal performance in different environments. Proper wire coating is essential for the safety and efficiency of electrical systems and is therefore an important aspect of wire production.

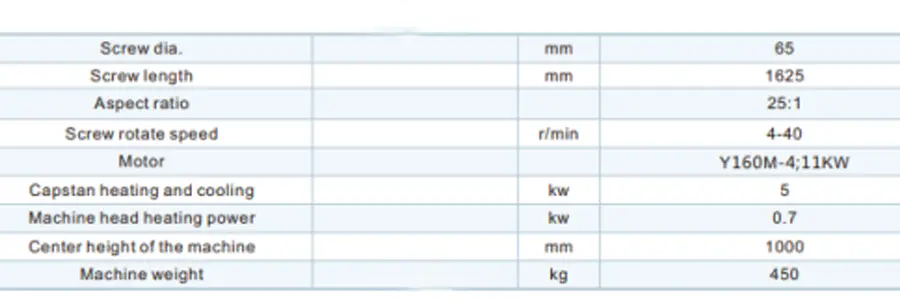

Wire Coating Technical Parameter