Second-hand PN500/1+6+12--1600 cage type stranding machine

Core functions:

- Specially used for the production of control cables, rubber cables, steel core aluminum stranded wires, etc.

- Supporting the stranding of new energy wires (1+6+12 structure is particularly suitable for multi-core cables)

Typical application scenarios:

- Multi-core cable cabling

- Precision cable manufacturing that requires back-twisting

- Large-section stranded conductor production

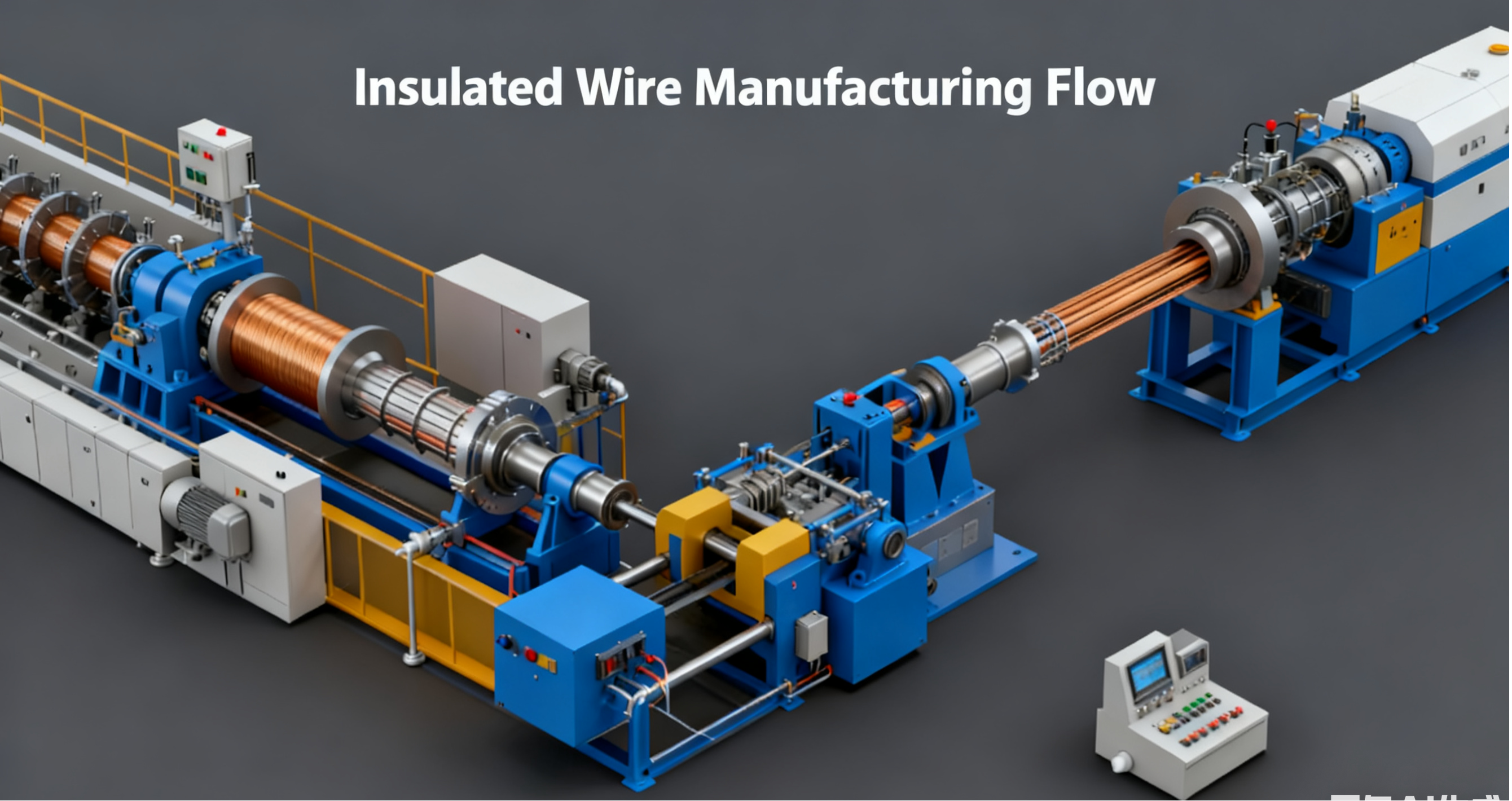

The entire production line consists of a pay-off rack, each section of the stranding cage, a junction die, a meter, a traction device, a take-up rack, a transmission system, an electric control system, and a safety protection system. The corresponding wrapping head and armor head are configured according to user needs.

ONE. Equipment use

Cage stranding machine is a special equipment for stranding control cables, rubber cables, steel strands, steel core aluminum strands, copper strands, aluminum strands and soft strands in power cable factories.

TWO. Main technical parameters

- Twisted single wire diameter: 1.5-4.0 mm

- Maximum stranding cross-section: 10-120 mm2

- Number of strands: 7, 19

- Twisting body speed 6, 12 reels: 50.4-120r/min

- Twisting speed: 5-50 rpm

- Stranding wire pitch 6, 12 reels: 48-824mm

- Traction line speed: 5.1-36.9m/min

- Specifications of the pay-off reel in the stranding cage: PN500 (Φ500×L375×d56)

- Center pay-off reel specifications: PN500 (Φ500×L375×d56)

- Take-up reel specifications: PN1600~PN2500mm

- Wire arrangement form: GP30 type of light bar wire arrangement

- Torque transmission machine: LJT132-25/4 type

- Lifting motor: 1.5 kw

- Main motor power: 22kW (electromagnetic speed regulating motor)

- Equipment center height: 1000mm

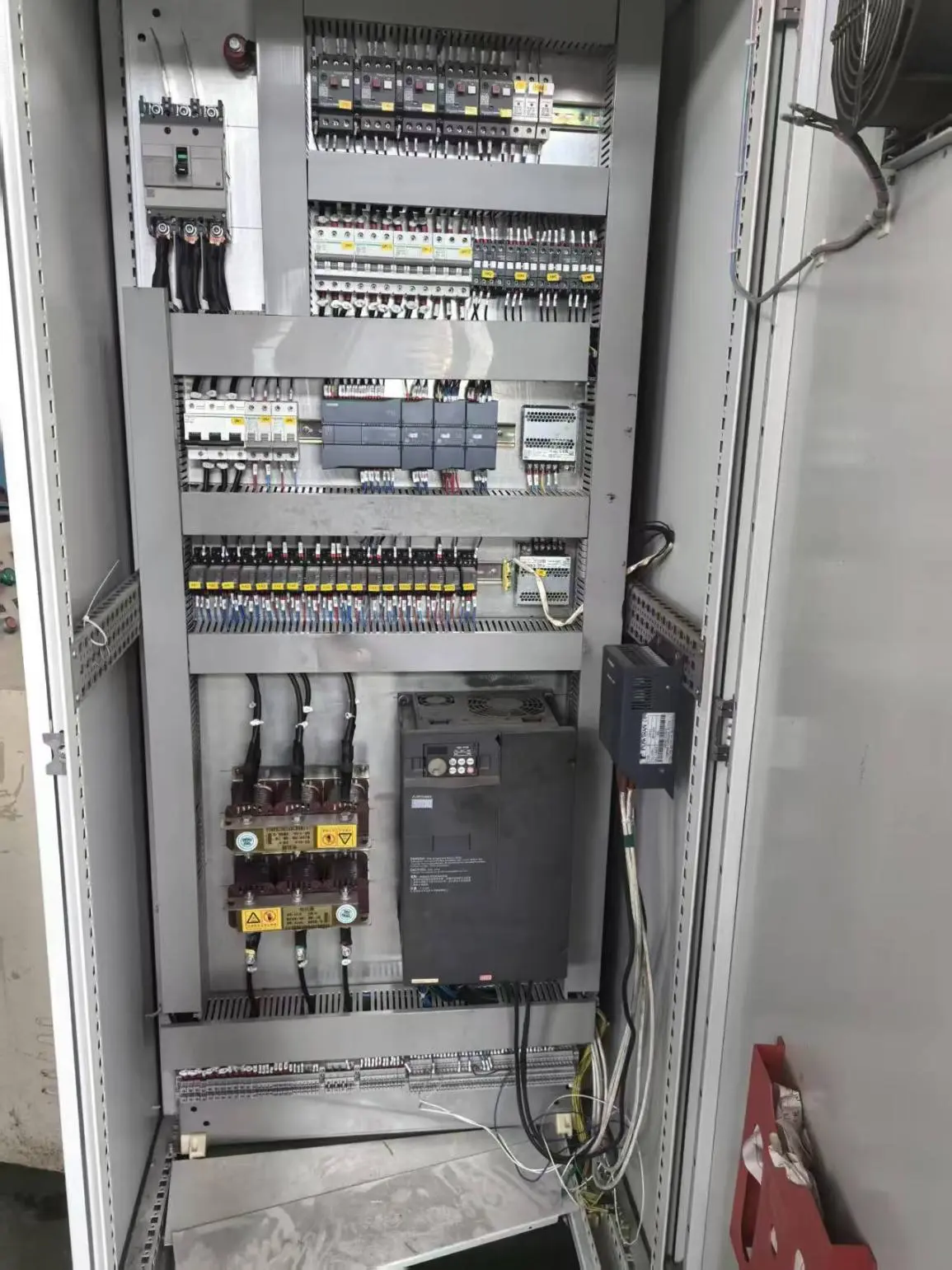

- Synchronous speed regulating electrical control cabinet

THREE. Main components

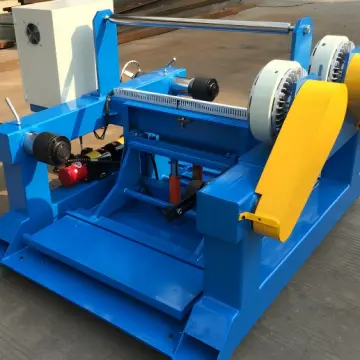

- Φ500 pay-off rack: 1 set

- Well-type conductor rack: 1 set

- 6, 12 reel stranding body: 1 set each

- Wire mold frame (including 1 set of press seat): 2 sets

- High-speed wrapping device: 1 set

- Mechanical meter: 1 set

- Φ2000 double traction device: 1 set

- Φ2500 shaftless take-up and arrangement rack: 1 set

- Mechanical transmission system: 1 set

- Electric control system: 1 set

- Safety fe