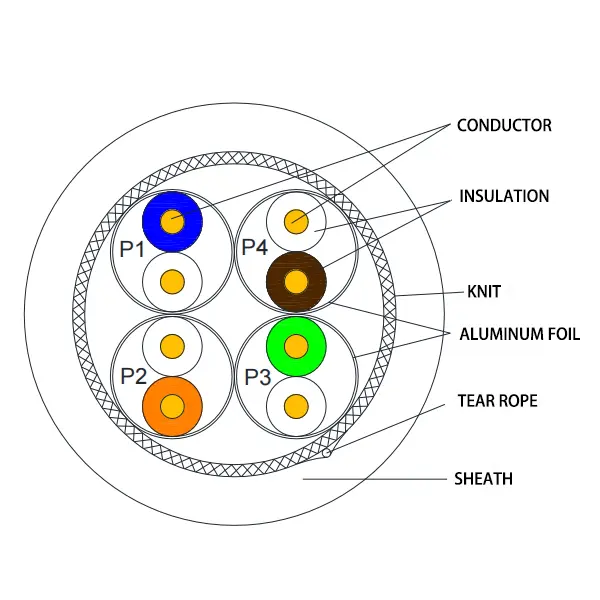

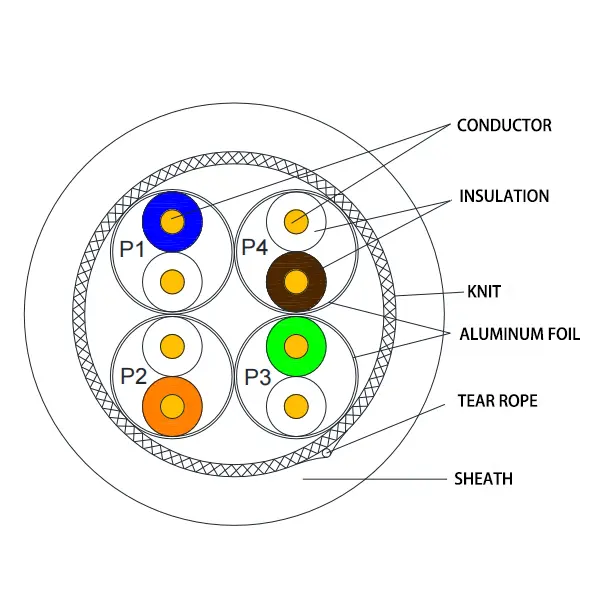

S/FTP Category 8 4-pair shielded low smoke zero halogen cable specification

Features

1. Complies with ANSI/TIA-568.2-D 2000MHz test

2. Use skin-to-skin physical foaming technology to improve the electrical performance of the product

3. Provides cable length marking to reduce waste

4. Support high-speed transmission of voice, data and video signals

5. Each wire pair is wrapped with aluminum foil, and the 4 pairs of twisted wires are shielded with metal mesh, which greatly reduces the loss of near-end crosstalk and far-end crosstalk, and provides reliable anti-external crosstalk.

Product Standards

ANSI/TIA-568.2-D-2018

ISO/IEC 11801-2017

Product images, specifications, dimensions

Product images

Specifications, dimensions, installation requirements

description2

Cable pairs |

4 right |

|

Line pair color |

White-blue, blue, white-orange, orange, white-green, green, white-brown, brown |

|

|

conductor |

structure |

Single strand |

Material |

Annealed round copper |

|

Wire Gauge |

22AWG |

|

|

insulation |

Core wire outer diameter |

1.52±0.10mm |

Material |

Physical foaming PE |

|

Color discrimination |

Color Bars |

|

Shielding Materials |

Single-sided aluminum foil/tinned copper wire |

|

Rip cord |

150D polyester straight mop |

|

|

jacket |

Sheath material |

LSZ |

Cable outer diameter |

8.5±0.3mm |

|

Average sheath thickness |

0.65±0.1mm |

|

Sheath printing |

SHIP-TECH SYSTEM CABLE S/FTP CAT8 4PAIRS 22AWG LSZ ISO11801 D281-D batch number 001M … 305M |

|

Rolling method |

Wooden coil flat |

|

Installation temperature |

0℃~ +60℃ |

|

Use and storage temperature |

-20℃~ +60℃ |

|

Cable reference net weight |

18.3kg/305m |

|

Product Performance

Mechanical properties

Elongation at break of conductor |

≥15% |

Insulation elongation at break |

≥200% |

Insulation tensile strength |

≥10MPa |

Sheath tensile strength before aging |

≥10MPa |

Tensile strength of sheath after aging (100℃±2℃, 168h) |

≥8MPa |

Change rate of tensile strength of sheath after aging |

±30% |

Sheath elongation at break before aging |

≥125% |

Elongation at break of sheath after aging (100℃±2℃, 168h) |

≥100% |

Change rate of elongation at break after sheath aging |

±30% |

Insulated wire core broken or mixed |

No disconnection or mixing |

Application

|

Characteristic impedance |

1-100MHZ |

100±15Ω |

100-250MHZ |

100±20Ω |

|

250-1000MHZ |

100±30Ω |

|

1000-2000MHZ |

100±35Ω |

|

DC resistance of a single conductor |

≤2.4Ω/30m |

|

DC resistance unbalance within the line pair |

≤2.0% |

|

Dielectric strength DC between conductors |

1000V, 1min, no breakdown |

|

Propagation Delay Difference |

≤13.5ns/30m |

|

Propagation Delay |

≤160ns/300m |

|

Working Capacitance |

≤5.6nF/100m |

|

Rated transfer rate (NVP) |

78% |

|

Insulation resistance |

≥5000MΩ·km +20℃ DC (100-500)V |

|

Transmission performance

|

frequency (MHz) |

attenuation (dB/30m) (Maximum) |

Return loss(dB) (Minimum) |

Near-end crosstalk attenuation Reduction(dB) (Minimum) |

Near-end crosstalk attenuation Power Sum(dB) (Minimum) |

ELE Attenuation(dB/30m) (Minimum) |

Equal level far end crosstalk attenuation Power reduction and (dB/30m) (Minimum) |

1 |

2.0 |

20.0 |

75.3 |

72.3 |

75.0 |

72.0 |

4 |

2.0 |

23.0 |

66.3 |

63.3 |

67.0 |

64.0 |

8 |

2.0 |

24.5 |

61.8 |

58.8 |

60.9 |

57.9 |

10 |

2.0 |

25.0 |

60.3 |

57.3 |

59.0 |

56.0 |

16 |

2.2 |

25.0 |

57.2 |

54.2 |

54.9 |

51.9 |

20 |

2.5 |

25.0 |

55.8 |

52.8 |

53.0 |

50.0 |

31.25 |

3.1 |

25.0 |

52.9 |

49.9 |

49.1 |

46.1 |

62.5 |

4.4 |

23.6 |

48.4 |

45.4 |

43.1 |

40.1 |

100 |

5.6 |

22.2 |

45.3 |

42.3 |

39.0 |

36.0 |

200 |

7.9 |

20.1 |

40.8 |

37.8 |

33.0 |

30.0 |

250 |

8.9 |

19.4 |

39.3 |

36.3 |

31.0 |

28.0 |

500 |

12.8 |

17.3 |

34.8 |

31.8 |

25.0 |

22.0 |

600 |

14.1 |

16.8 |

33.6 |

30.6 |

23.4 |

20.4 |

1000 |

18.6 |

15.2 |

30.3 |

27.3 |

19.0 |

16.0 |

1500 |

23.2 |

14.0 |

27.7 |

24.7 |

15.5 |

12.5 |

2000 |

27.2 |

13.1 |

25.8 |

22.8 |

13.0 |

10.0 |

Flame retardant properties

Meets the flame vertical spread test for single insulated thin wires and cables - diffusion type flame test method

Distance between the lower edge of the upper support and the carbonization starting point |

>50 mm |

Distance between the lower edge of carbonization and the lower edge of the upper bracket |

≤540 mm |

Product Packaging

Packing specification: (Wooden reel flat winding)

Plate surface*plate inner diameter*plate inner height (cm) |

Φ40*Φ16*L24cm |

Cable length |

305m/wooden tray |

Reference weight of the whole plate |

20.8kg |

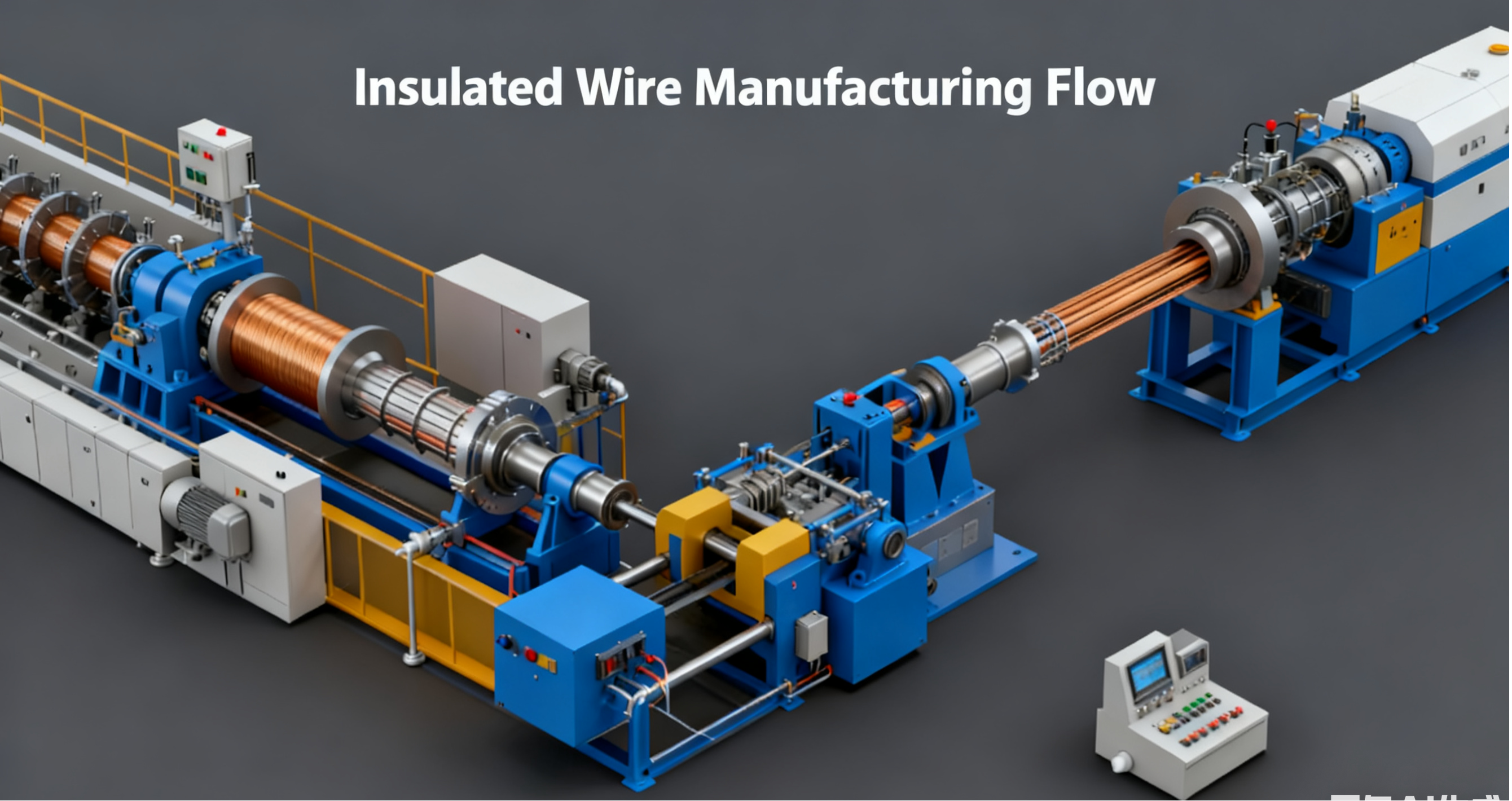

We have mastered the manufacturing and know-how of wire drawing and annealing three-layer co-extruded foamed insulated tandem line, twist-free pair twisted shielded tapping machine, untwisted payoff single-twisted cabling machine, etc. Welcome to cooperate, communicate and customize the purchase.