01

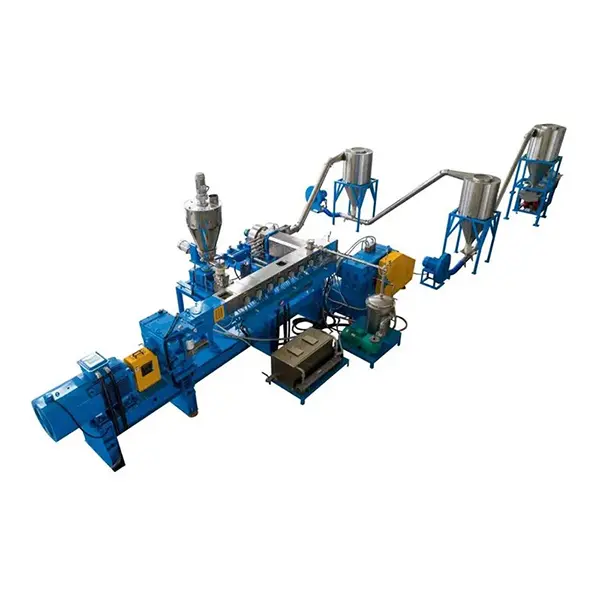

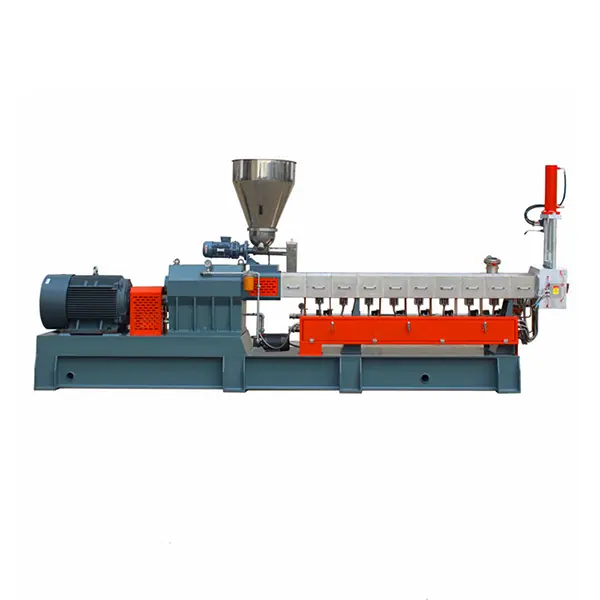

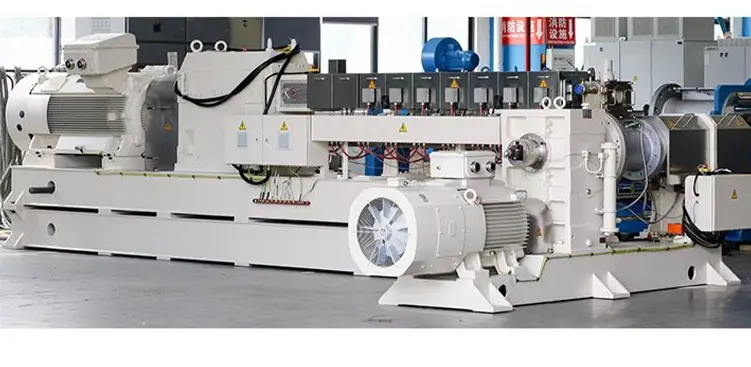

PVC cable compounding double-stage twin-screw pelletizing line

Two-stage extruder granulation production line

In order to fully mix in the first stage, parallel co-rotating or parallel counter-rotating twin screws are used.

The second stage is a low-speed rotating single-screw extruder, which combines and complements the advantages of the two and is widely used in granulation of various heat-sensitive material systems, large-capacity devolatilization and other operations.

The mixer has efficient plasticizing, mixing and shearing dispersion, and no head back pressure reflux, which avoids local high shear overheating. The single screw cooling, low speed and high pressure extrusion also avoids the contradiction of overheating.

This decomposes the process functions and increases independent operating variables, which is conducive to the step-by-step optimization of each process and higher efficiency and production capacity.

description2

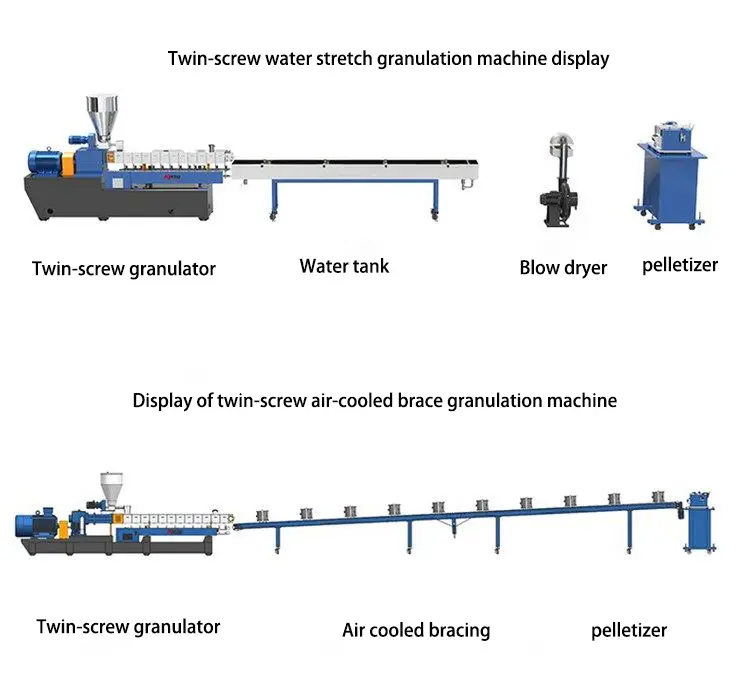

The simplest configuration and the cheapest investment: twin-screw Plastic monofilament cooling pelletizing unit, twin-screw Plastic monofilament air blast cooling pelletizing unit

PVC CABLE MATERIAL GRANULATION UNIT PROCESS INTRODUCTION

1,After the PVC material is put into the high-speed mixer for mixing, the powdered material is fed into the upper-stage parallel twin-screw extruder through a screw feeder.

2,The upper parallel twin-screw extruder mixes the materials evenly, completes plasticizing and mixing at a temperature of 140-160°C, and fully disperses them. The extruded mixed material then becomes a melt (temperature at 130-140°C) and falls directly into the large-diameter lower single-screw extruder.

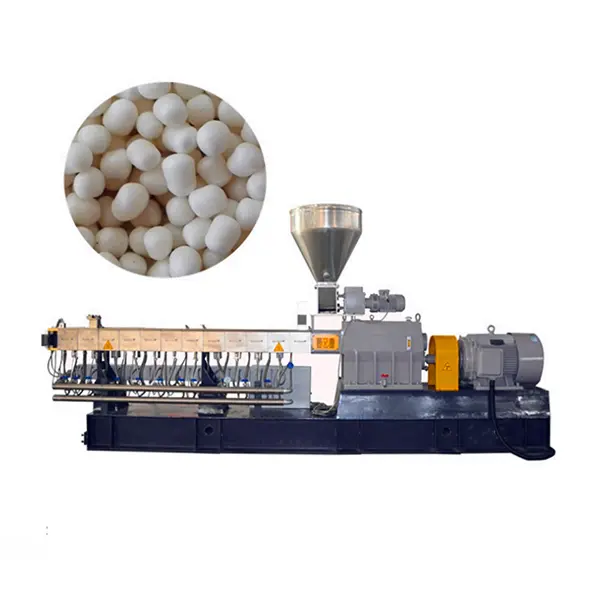

3,The lower-stage single-screw extruder granulates the 120°C melt at low speed, high pressure and cooling state. The temperature has dropped to 120-140 degrees Celsius during extrusion. Only then can the air-cooled die surface hot pelletizing be completed, and it is guaranteed that the pellets will not stick during the pelletizing process.

4,The particles cut off by the air-cooled die surface are cooled by the secondary air-cooled cyclone separator until the particle temperature drops to room temperature so that they can be sent to the finished product warehouse for packaging.

High speed mixer---screw automatic feeder---twin screw mixer---single screw granulator---blow hot cutting die head---first cyclone separator---second cyclone separator---extended air-cooled vibrating screen---finished product silo.

Because the formula of PVC cable materials is very easy to adjust, there are many formula examples that can be shared, which will be introduced in detail later.

Because of poor formulation, the surface of PVC cable materials is most likely to be rough, one is bumps and the other is pitting.

The lumps are mainly composed of some powder aggregates that are unevenly dispersed during mixing. They cannot be plasticized during the extrusion process and are thus wrapped by the plasticized PVC material and extruded together from the die, forming in the cable material.

Fisheye resin and PVC resin particles that have not fully absorbed the plasticizer will also form lumps. When the situation is not serious, they are generally small and appear as pitting.

Nowadays, the formulation pursues finer and more fillers. If the surface treatment of the filler is not good, the mixing effect will be poor and the probability of agglomeration will be relatively high. However, the degree of agglomeration and whether it is serious in the cable material will affect the performance.