Top 10 best-selling cable varieties and price trends in the Indian market (updated in 2025)

According to industry knowledge, common cables in India include power cables (low voltage, medium voltage), control cables, communication cables (optical fiber, coaxial), building wires (PVC insulation), solar cables, etc. In addition, there may be specific demand for water-blocking cables and fire-resistant cables, especially for infrastructure and energy projects.

In terms of price, material costs (copper, aluminum), certification requirements (ISI, BIS) and tariffs need to be considered. Suppliers may include local manufacturers such as Polycab, Havells, and local distributors of international brands.

PART ONE,Top 10 best-selling cable in the Indian market

The following is an overview of the best-selling cable varieties, price ranges and major suppliers based on public data and industry trend analysis of the Indian cable market, suitable for purchase reference on the www.indiamart.com platform:

1.Cable Type : PVC insulated building wire (2.5 sq.mm)

Application scenario : residential/commercial power distribution

Price Range (Rs./m) : 15-25

Core suppliers (Indiamart certified) : Polycab, Havells, Finolex

Fully automatic Insulation and Rolling line for building wire

Extrusion method: single layer, double layer, double color insulation extrusion

Applicable conductor: 1.5mm2 , 2-6mm2

Finished outer diameter: Ф1.0mm-Ф7.0mm

70mm main extrusion capacity: 130kg/h (soft PVC).

35mm auxiliary extrusion capacity: 15kg/h (soft PVC)

Speed:200m/min (max)

600/1000V IEC 60502 standard PVC insulation, PVC sheath, non-armored power cable (single core)

application

IEC 60502-1 600/1000V PVC insulated, PVC sheathed non-armoured power cables are mainly used for fixed installation in industrial areas, buildings and similar applications but not directly buried in the ground or in pipelines. This type of cable has been certified by TUV.

standard

Designed to IEC 60502-1

Certification

TUV certificate (Z1 17 08 98200 008)

Fire performance

| Flame retardancy (single vertical cable test) | IEC 60332-1-2 |

Rated voltage

600/1000V

Cable structure

| conductor | Annealed copper conductor in accordance with IEC 60228 Class 2. |

| insulation | Complies with standard IEC 60502-1 PVC/A. |

| Outer sheath | Conforms to standard IEC 60502-1 extruded PVC type ST1/ST2. |

| Outer sheath optional | Can provide UV resistance, hydrocarbon resistance, oil resistance, rodent resistance, termite resistance and other properties. Compliance with fire protection standards (IEC60332-1, IEC60332-3, UL 1581, UL 1666, etc.) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided according to customer requirements. |

Chromatography

| Insulation color | Brown or blue, other colors available upon request. |

| Sheath color | Black, other colors available upon request. |

Mechanical and electrical properties

| Maximum operating temperature range | 70°C | ||||||

| Maximum short circuit temperature (5s) |

| ||||||

| |||||||

| Minimum bending radius |

| ||||||

| |||||||

Structural parameters

| conductor | FGD300 1RV-R | ||||

| Number of cores x cross-sectional area | Conductor Type | Nominal insulation thickness | Nominal sheath thickness | Nominal overall diameter | Approximate weight |

| No.xmm 2 |

| mm | mm | mm | kg/km |

| 1x1.5 | 2 | 0.8 | 1.4 | 5.8 | 55 |

| 1x2.5 | 2 | 0.8 | 1.4 | 6.2 | 70 |

| 1x4.0 | 2 | 1 | 1.4 | 7.1 | 98 |

| 1x6.0 | 2 | 1 | 1.4 | 7.6 | 124 |

| 1x10 | 2 | 1 | 1.4 | 8.4 | 173 |

| 1x16 | 2 | 1 | 1.4 | 9.3 | 240 |

| 1x25 | 2 | 1.2 | 1.4 | 10.8 | 350 |

| 1x35 | 2 | 1.2 | 1.4 | 11.9 | 468 |

| 1x50 | 2 | 1.4 | 1.4 | 13.6 | 646 |

| 1x70 | 2 | 1.4 | 1.4 | 15 | 854 |

| 1x95 | 2 | 1.6 | 1.5 | 17.2 | 1154 |

| 1x120 | 2 | 1.6 | 1.5 | 18.6 | 1428 |

| 1x150 | 2 | 1.8 | 1.6 | 20.6 | 1764 |

| 1x185 | 2 | 2 | 1.7 | 22.7 | 2160 |

| 1x240 | 2 | 2.2 | 1.8 | 25.5 | 2796 |

| 1x300 | 2 | 2.4 | 1.9 | 28.1 | 3449 |

| 1x400 | 2 | 2.6 | 2 | 31.8 | 4570 |

| 1x500 | 2 | 2.8 | 2.1 | 35 | 5641 |

| 1x630 | 2 | 2.8 | 2.2 | 38.3 | 7015 |

| 1x800 | 2 | 2.8 | 2.3 | 42.1 | 8798 |

| 1x1000 | 2 | 3 | 2.5 | 46.7 | 10970 |

Electrical properties

| Conductor operating temperature | 70°C |

| Ambient temperature | 30°C |

Current carrying capacity (Amp) According to BS 7671:2008 table 4D1A

| Conductor cross-sectional area | Reference Method A (Attached to a duct on a thermally insulated wall) | Reference Method B (Attached to a conduit in a wire duct or wall, etc.) | Reference method C (directly clamp with a clip) | Reference Method F (In a cable box with aperture, horizontal or vertical) | |||||||

| 2 cables, single-phase AC or DC | 3 or 4 three-phase AC power lines | 2 cables single phase AC or DC | 3 or 4 three-phase AC power lines | 2 cables single phase AC or DC. Horizontally adjacent | 3 or 4 three-phase AC cables are separated horizontally and next to each other or three phases are separated | 2 cables single phase AC or DC cables separated horizontally | 3 cables, three-phase AC cables are separated horizontally | 3 cables, three phases of three-phase AC cable separated | 2 cables single phase AC or DC or 3 cables three phase AC the cables are split horizontally | ||

| level | vertical | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| mm² | A | A | A | A | A | A | A | A | A | A | A |

| 1 | 11 | 10.5 | 13.5 | 12 | 15.5 | 14 | - | - | - | - | - |

| 1.5 | 14.5 | 13.5 | 17.5 | 15.5 | 20 | 18 | - | - | - | - | - |

| 2.5 | 20 | 18 | 24 | 21 | 27 | 25 | - | - | - | - | - |

| 4 | 26 | 24 | 32 | 28 | 37 | 33 | - | - | - | - | - |

| 6 | 34 | 31 | 41 | 36 | 47 | 43 | - | - | - | - | - |

| 10 | 46 | 42 | 57 | 50 | 65 | 59 | - | - | - | - | - |

| 16 | 61 | 56 | 76 | 68 | 87 | 79 | - | - | - | - | - |

| 25 | 80 | 73 | 101 | 89 | 114 | 104 | 131 | 114 | 110 | 146 | 130 |

| 35 | 99 | 89 | 125 | 110 | 141 | 129 | 162 | 143 | 137 | 181 | 162 |

| 50 | 119 | 108 | 151 | 134 | 182 | 167 | 196 | 174 | 167 | 219 | 197 |

| 70 | 151 | 136 | 192 | 171 | 234 | 214 | 251 | 225 | 216 | 281 | 254 |

| 95 | 182 | 164 | 232 | 207 | 284 | 261 | 304 | 275 | 264 | 341 | 311 |

| 120 | 210 | 188 | 269 | 239 | 330 | 303 | 352 | 321 | 308 | 396 | 362 |

| 150 | 240 | 216 | 300 | 262 | 381 | 349 | 406 | 372 | 356 | 456 | 419 |

| 185 | 273 | 245 | 341 | 296 | 436 | 400 | 463 | 427 | 409 | 521 | 480 |

| 240 | 321 | 286 | 400 | 346 | 515 | 472 | 546 | 507 | 485 | 615 | 569 |

| 300 | 367 | 328 | 458 | 394 | 594 | 545 | 629 | 587 | 561 | 709 | 659 |

| 400 | - | - | 546 | 467 | 694 | 634 | 754 | 689 | 656 | 852 | 795 |

| 500 | - | - | 626 | 533 | 792 | 723 | 868 | 789 | 749 | 982 | 920 |

| 630 | - | - | 720 | 611 | 904 | 826 | 1005 | 905 | 855 | 1138 | 1070 |

| 800 | - | - | - | - | 1030 | 943 | 1086 | 1020 | 971 | 1265 | 1188 |

| 1000 | - | - | - | - | 1154 | 1058 | 1216 | 1149 | 1079 | 1420 | 1337 |

Voltage drop (A/M) according to BS 7671:2008 table 4D1B

| Conductor cross-sectional area | 2 cables DC | 2 cables single phase AC | 3 or 4 three-phase AC power lines | |||||||||||||||||||

| Reference Methods A and B (Attached to Wireway or Conduit) | Reference Method C & F (directly clamped with wire clamps, placed in cable ducts or exposed to air) | Reference Method A & B (Attached to Wireway or Conduit | Reference Method C & F (directly clamped with wire clamps, placed in cable ducts or exposed to air) | |||||||||||||||||||

|

|

|

| Cable adjacent | Cable separation* | Cable three phases adjacent | Cables are adjacent horizontally | Horizontal cable separation* | |||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||||||||||||||

| mm² | mV/A/m | |||||||||||||||||||||

| 1 | 44 | 44 | 44 | 44 | 38 | 38 | 38 | 38 | ||||||||||||||

| 1.5 | 29 | 29 | 29 | 29 | 25 | 25 | 25 | 25 | ||||||||||||||

| 2.5 | 18 | 18 | 18 | 18 | 15 | 15 | 15 | 15 | ||||||||||||||

| 4 | 11 | 11 | 11 | 11 | 9.5 | 9.5 | 9.5 | 9.5 | ||||||||||||||

| 6 | 7.3 | 7.3 | 7.3 | 7.3 | 6.4 | 6.4 | 6.4 | 6.4 | ||||||||||||||

| 10 | 4.4 | 4.4 | 4.4 | 4.4 | 3.8 | 3.8 | 3.8 | 3.8 | ||||||||||||||

| 16 | 2.8 | 2.8 | 2.8 | 2.8 | 2.4 | 2.4 | 2.4 | 2.4 | ||||||||||||||

|

|

| r | x | z | r | x | z | r | x | With | r | x | With | r | x | With | r | x | With | r | x | With |

| 25 | 1.75 | 1.8 | 0.33 | 1.8 | 1.75 | 0.2 | 1.75 | 1.75 | 0.29 | 1.8 | 1.5 | 0.29 | 1.55 | 1.5 | 0.175 | 1.5 | 1.5 | 0.25 | 1.55 | 1.5 | 0.32 | 1.55 |

| 35 | 1.25 | 1.3 | 0.31 | 1.3 | 1.25 | 0.195 | 1.25 | 1.25 | 0.28 | 1.3 | 1.1 | 0.27 | 1.1 | 1.1 | 0.17 | 1.1 | 1.1 | 0.24 | 1.1 | 1.1 | 0.32 | 1.15 |

| 50 | 0.93 | 0.95 | 0.3 | 1 | 0.93 | 0.19 | 0.95 | 0.93 | 0.28 | 0.97 | 0.81 | 0.26 | 0.85 | 0.8 | 0.165 | 0.82 | 0.8 | 0.24 | 0.84 | 0.8 | 0.32 | 0.86 |

| 70 | 0.63 | 0.65 | 0.29 | 0.72 | 0.63 | 0.185 | 0.66 | 0.63 | 0.27 | 0.69 | 0.56 | 0.25 | 0.61 | 0.55 | 0.16 | 0.57 | 0.55 | 0.24 | 0.6 | 0.55 | 0.31 | 0.63 |

| 95 | 0.46 | 0.49 | 0.28 | 0.56 | 0.47 | 0.18 | 0.5 | 0.47 | 0.27 | 0.54 | 0.42 | 0.24 | 0.48 | 0.41 | 0.155 | 0.43 | 0.41 | 0.23 | 0.47 | 0.4 | 0.31 | 0.51 |

| 120 | 0.36 | 0.39 | 0.27 | 0.47 | 0.37 | 0.175 | 0.41 | 0.37 | 0.26 | 0.45 | 0.33 | 0.23 | 0.41 | 0.32 | 0.15 | 0.36 | 0.32 | 0.23 | 0.4 | 0.32 | 0.3 | 0.44 |

| 150 | 0.29 | 0.31 | 0.27 | 0.41 | 0.3 | 0.175 | 0.34 | 0.29 | 0.26 | 0.39 | 0.27 | 0.23 | 0.36 | 0.26 | 0.15 | 0.3 | 0.26 | 0.23 | 0.34 | 0.26 | 0.3 | 0.4 |

| 185 | 0.23 | 0.25 | 0.27 | 0.37 | 0.24 | 0.17 | 0.29 | 0.24 | 0.26 | 0.35 | 0.22 | 0.23 | 0.32 | 0.21 | 0.145 | 0.26 | 0.21 | 0.22 | 0.31 | 0.21 | 0.3 | 0.36 |

| 240 | 0.18 | 0.195 | 0.26 | 0.33 | 0.185 | 0.165 | 0.25 | 0.185 | 0.25 | 0.31 | 0.17 | 0.23 | 0.29 | 0.16 | 0.145 | 0.22 | 0.16 | 0.22 | 0.27 | 0.16 | 0.29 | 0.34 |

| 300 | 0.145 | 0.16 | 0.26 | 0.31 | 0.15 | 0.165 | 0.22 | 0.15 | 0.25 | 0.29 | 0.14 | 0.23 | 0.27 | 0.13 | 0.14 | 0.19 | 0.13 | 0.22 | 0.25 | 0.13 | 0.29 | 0.32 |

| 400 | 0.105 | 0.13 | 0.26 | 0.29 | 0.12 | 0.16 | 0.2 | 0.115 | 0.25 | 0.27 | 0.12 | 0.22 | 0.25 | 0.105 | 0.14 | 0.175 | 0.105 | 0.21 | 0.24 | 0.1 | 0.29 | 0.31 |

| 500 | 0.086 | 0.11 | 0.26 | 0.28 | 0.098 | 0.155 | 0.185 | 0.093 | 0.24 | 0.26 | 0.1 | 0.22 | 0.25 | 0.086 | 0.135 | 0.16 | 0.086 | 0.21 | 0.23 | 0.081 | 0.29 | 0.3 |

| 630 | 0.068 | 0.094 | 0.25 | 0.27 | 0.081 | 0.155 | 0.175 | 0.076 | 0.24 | 0.25 | 0.08 | 0.22 | 0.24 | 0.072 | 0.135 | 0.15 | 0.072 | 0.21 | 0.22 | 0.066 | 0.28 | 0.29 |

| 800 | 0.053 | - | - | - | 0.068 | 0.15 | 0.165 | 0.061 | 0.24 | 0.25 | - | - | - | 0.06 | 0.13 | 0.145 | 0.06 | 0.21 | 0.22 | 0.053 | 0.28 | 0.29 |

| 1000 | 0.042 | - | - | - | 0.059 | 0.15 | 0.16 | 0.05 | 0.24 | 0.24 | - | - | - | 0.052 | 0.13 | 0.14 | 0.052 | 0.2 | 0.21 | 0.044 | 0.28 | 0.28 |

Note: *When the cable spacing is greater than one cable diameter, the voltage drop is greater.

r = conductor resistance at operating temperature

x = reactance

z = impedance

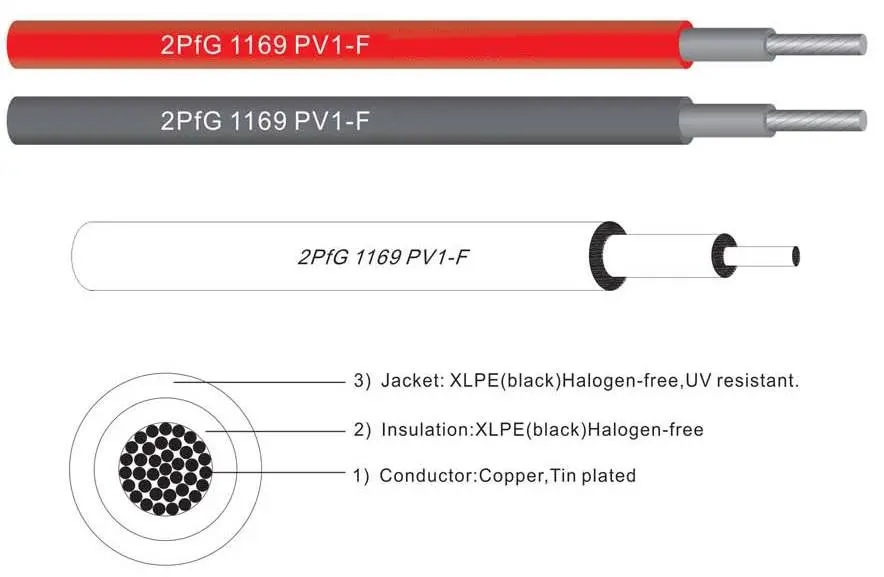

2.Cable Type : Solar DC Cable (4mm²)

Application scenario : photovoltaic power station component connection

Price Range (Rs./m) : 80-120

Core suppliers (Indiamart certified) : RR Kabel, LAPP India, Ultracab

application

This product is suitable for indoor and outdoor solar photovoltaic system circuit connections under extreme climatic conditions.

standard

2PfG 1169/08.2007 (PV1-F)

structure

Conductor: Stranded tinned copper wire in accordance with DIN VDE 0295 and IEC 60228 Class 5

Insulation: Electron beam cross-linked, low smoke zero halogen flame retardant compound

Sheath: Electron beam cross-linked, low smoke zero halogen flame retardant compound, black

Electrical properties

Rated voltage U0/U: 0.6/1 kV AC; 0.9/1.5 kV DC

Maximum permissible AC voltage: 1.8 kV DC (conductor/conductor, no grounding system, circuit without load)

Insulation resistance: 1000 MΩ-km

Spark test: 6000 Vac (8400 Vdc)

Withstand voltage: 6500 Vac for 5 min

Thermal properties

Indoor temperature: -40℃ ~ +90℃

Maximum conductor temperature: IEC/EN 60216-1 120℃ (20000h)

Short circuit temperature: 200℃/5 sHeat

resistance test: EN 60216-2 (temperature is +120° C)

High temperature pressure test: EN 60811-3-1Damp

heat resistance: EN60068-2-78, 85% humidity

Mechanical properties

Minimum bending radius: 4×OD (fixed), 5×OD (flexing)

Dynamic penetration: 2 PfG 1169/08.2007 Annex F

Slot propagation: 2 PfG 1169/08.2007 Annex G

Tensile strength and elongation of insulation and sheath: EN 60811

Expected service life: 25 years

Chemical properties

Ozone resistant: EN 50396 part 8.1.3 method B

Weathering and UV resistant: HD 605/A1

Ammonia resistant

Good oil and chemical resistance

Good wear and ageing resistance

Acid and alkali resistant: According to EN 60811-2-1 (oxalic acid & sodium hydroxide)

EC Index

The cable complies with European standards CE 2006/95/EC (Low Voltage Directive) and RoHS 2002/95/EC (Restriction of the use of hazardous substances)

Fire performance

Flame retardant according to EN 50265-2-1, IEC 60332-1, VDE 0482-332-1-2, DIN EN 60332-1-2

Low smoke performance according to IEC 61034, EN 50268

Halogen-free according to EN 50267-2-1, IEC 60754-1

Low corrosive gas performance according to EN 50267-2-2, IEC 60754-2

Specifications and dimensions

| Number of cores & nominal cross-sectional area | Number of strands/cable | Nominal conductor diameter | Nominal insulation thickness | Nominal sheath thickness | Nominal outer diameter | Nominal Weight |

| No. ×mm² | - | mm | mm | mm | mm | kg/km |

| 1×1.5 | 30/0.25 | 1.58 | 1.14 | 0.82 | 5.4 | 52 |

| 1×2.5 | 50/0.25 | 2.04 | 1.14 | 0.82 | 5.8 | 67 |

| 1×4.0 | 56/0.30 | 2.59 | 1.14 | 0.82 | 6.4 | 87 |

| 1×6.0 | 84/0.30 | 3.17 | 1.14 | 0.82 | 7.0 | 113 |

| 1×10 | 78/0.40 | 4.07 | 1.52 | 0.82 | 8.6 | 178 |

| 1×16 | 128/0.40 | 5.22 | 1.52 | 0.82 | 9.8 | 254 |

| 1×25 | 199/0.40 | 6.51 | 1.52 | 0.82 | 11.1 | 363 |

| 1×35 | 279/0.40 | 7.71 | 1.52 | 0.82 | 12.3 | 473 |

Current carrying capacity

| Conductor cross-sectional area | AWG | Maximum conductor resistance at 20°C | Current carrying capacity | ||

| Single cable exposed to air | Single | Several | |||

| mm² | - | Ω | A | A | A |

| 1.5 | 16 | 13.7 | 30 | 29 | twenty four |

| 2.5 | 14 | 8.21 | 41 | 39 | 33 |

| 4 | 12 | 5.09 | 55 | 52 | 44 |

| 6 | 10 | 3.39 | 70 | 67 | 57 |

| 10 | 8 | 1.95 | 98 | 93 | 79 |

| 16 | 6 | 1.24 | 132 | 125 | 107 |

| 25 | 4 | 0.795 | 176 | 167 | 142 |

| 35 | 2 | 0.565 | 218 | 207 | 176 |

Conversion coefficient for deviation temperature

| Indoor temperature ℃ | Transformation coefficient |

| Up to 60 | 1.00 |

| 70 | 0.91 |

| 80 | 0.82 |

| 90 | 0.71 |

| 100 | 0.58 |

| 110 | 0.41 |

The cumulative reduction factor in accordance with IEC60364-5-52 standard is shown in Table B.52-17

3.Cable type : Water-blocking optical fiber composite overhead ground wire (24 cores)

Application scenario : Telecom backbone network/submarine communication

Price Range (Rs./m) : 350-600

Core Supplier (Indiamart certified) : Sterlite Tech, Paramount Cables

4.Cable type : Aluminum core aerial insulated cable (AAC)

Application scenario : Rural power grid transformation

Price Range (Rs./m) : 40-70

Core suppliers (Indiamart certified) : KEI Industries, Diamond Power

Tips: A batch of high-quality Second-Hand Cable Equipment:

① 8 sets of 90% new tapping machine,2500 Gantry take-up,1250 Caterpillar Traction, 4 head non-woven fabric wrapping head.

② Hefei Smarter Technology Group Corp. ,2 sets of 2015 produced Large bearing Tubular Strander.

③ Jiangsu Handing Cable Machinery,1 set of 90% new 1000 Cantilever type Single twist cabling machine, 8 pcs pay-offs with motor, and 1 pcs wrapping head

④ Two sets of twin-screw grouting machines for fire-resistant cables, 2500 Gantry take-up, 2000 Caterpillar Traction.

⑤ Hefei Smarter Technology Group Corp. ,almost new,630/61 Rigid Frame Stranding Machine,bottom lumped loading system.

⑥ almost new double Copper Rod Breakdown Machine with Continuous Annealer,Double spool take-up,Barrel coiling package.

⑨ 90% of the new 800 wire bunching machine,8 pcs pay offs with motor.

⑩ Jiangsu Handing Cable Machinery,1250 Cantilever type Single twist cabling machine, 8 magnetic powder tension pay-offs.

⑪ Hefei Smarter Technology Group Corp. ,630/1+6 Large bearing Tubular Strander.

⑫ 500/1+6 Tubular Strander.

⑬ 500/12+18 Rigid Frame Stranding Machine.

⑭ 800 Barrel coiling package, 40 pcs.

5 . Cable type : Fire-resistant LSZH cable (fire resistance rating: IEC 60332)

Application scenario : subway/high-rise building emergency system

Price Range (Rs./m) : 200-350

Core Supplier (Indiamart Certified) : Nexans India, Gupta Power

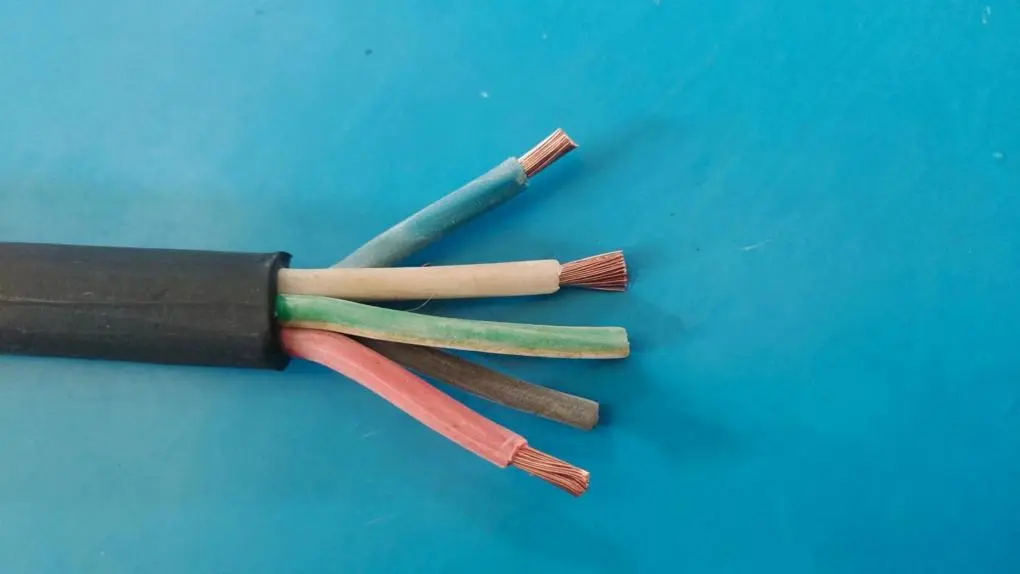

6 . Cable type : Rubber soft cable (3 cores, oil resistant)

Application scenario : power supply for industrial machinery and equipment

Price Range (Rs./m) : 120-200

Core Supplier (Indiamart Certified) : Anchor by Panasonic, V-Guard

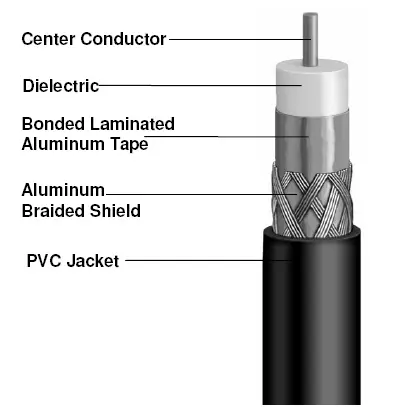

7 , Cable type : coaxial cable (RG6 type)

Application scenario : Cable TV/monitoring system

Price Range (Rs./m) : 25-45

Core suppliers (Indiamart certified) : GANPATI ELECTRONICS , AMP Netconnect , Belden India

RG 6 Coaxial Cable

structure

| Inner conductor | Copper Clad Steel (CCS) | Φ1.02 mm |

| insulation | Foamed PE | Φ4.57 ±0.20 mm |

| Tape shield (shield 1) | Aluminum-plastic composite polyester belt |

|

| Shielding coverage |

| 100% |

| Outer conductor (shield 2) | Aluminum Wire | 96 x 0.12 mm |

| Shielding coverage |

| 82% |

| jacket | PVC / Low Smoke Zero Halogen | Φ6.91 mm |

Electrical and physical properties

| Characteristic impedance | 75±5 Ohm |

| Nominal capacitance | 54 pF/m |

| Propagation speed | 83% |

| Insulation resistance | >5000 Mohm.Km |

| Inner conductor resistance | 21.7 Ohm/Km |

| Outer conductor resistance | 24.1Ohm/Km |

| Operating temperature range | -30 °C - +70 °C |

| Cable weight (approx.) | 45 Kg/Km |

attenuation

| Frequency (MHz) | Attenuation (dB/100 m) | Attenuation(dB/100ift) |

| 50 | 5.0 | 1.5 |

| 100 | 6.7 | 2.0 |

| 200 | 9.5 | 2.9 |

| 400 | 14.1 | 4.2 |

| 700 | 19.9 | 6.0 |

| 900 | 23.2 | 7.0 |

| 1000 | 24.8 | 7.5 |

| 1350 | 29.9 | 9.0 |

| 1750 | 35.1 | 10.5 |

| 2150 | 37.9 | 11.4 |

| 2500 | 39.0 | 11.7 |

8 . Cable type : Medium voltage cross-linked polyethylene cable (11kV)

Application scenario : Urban power transmission and distribution network

Price Range (Rs./m) : 450-800

Core Supplier (Indiamart Certified) : APAR Industries, Torrent Cables

Tips: List of high-quality second-hand cable equipment for the entire factory (located in Fujian, China)

① Nanjing Yigong Electrical Equipment Company,35KV Triple-layer Extrusion Dry ② Cross-linking Cable Production line,Eight stage heating, double Gantry take-up and pay-off.

③ German SIKORA X-RAY 6000 PRO Cable derivometer.

④ Hefei Smarter Technology Group Corp. ,3150/1+4 CPD Drum Twister With Caterpillar,5 sets of pay-off.

⑤ Concentric Type Copper Tape Screening Machine,Gantry take-up and pay-off.

⑥ Concentric Type Steel tape Screening Machine,Gantry take-up and pay-off.

⑦ Wuxi Hengtai(HNT)Cable Machinery Manufacture company,150 plastic sheath extruder,Double Caterpillar Traction,Gantry take-up and pay-off.

⑧ SHANGHAI LANPO HIGH VOLTAGE TECHNOLOGY & EQUIPMENT COMPANY,10KV/35KV cable withstand voltage partial discharge test

⑨ Hefei Smarter Technology Group Corp. ,1+6 Φ1000 CLYG Planetary Laying up Machine.

⑩ Wuxi Hengtai(HNT)Cable Machinery Manufacture company,120+65 Double layer plastic sheath extruder,Gantry take-up.

⑪ Wuxi Hengtai(HNT)Cable Machinery Manufacture company,120 single layer plastic sheath extruder,Gantry take-up

⑫ Tianjin TianLan electric machinery,90+90 Double layer rubber sheath extruder,Gantry take-up.

⑬ Tianjin TianLan electric machinery,70+70 Double layer rubber insulation extruder,Gantry take-up.

9 . Cable type : Marine cable (CXFR type)

Application scenario : Ship power and control system

Price Range (Rs./m) : 280-500

Core Supplier (Indiamart certified) : L&T Electrical, Cords Cable

10.Cable type : Electric vehicle charging pile cable (Type 2)

Application scenario : public charging station/home charger

Price Range (Rs./m) : 600-1,200

Core suppliers (Indiamart certified) : TE Connectivity, HUBER+SUHNER

What is liquid-cooled supercharging

Liquid-cooled supercharging is to set up a special liquid circulation channel between the cable and the charging gun, add liquid coolant to the channel for heat dissipation, and promote the circulation of the coolant through a power pump, so as to bring out the heat generated during the charging process and reduce the cable temperature. Compared with the traditional air cooling system, the liquid cooling system has more sufficient cooling performance and is more efficient, which greatly improves the working efficiency and life of the charging system.

Charging cables for electric vehicles

Liquid-cooled charging cable

application

The application mode of oil-cooled charging cable is mainly used to connect the charging equipment of electric vehicles to the charging infrastructure, thereby providing fast power transmission for electric vehicles, and equipped with a certain number of signal and control lines to ensure accurate control and safe and error-free operation of the entire charging process. The structure of oil-cooled charging cable is mainly composed of power main core, ground wire, signal wire or shielded wire group, return pipe, filler and reinforcing rope combination. The DC+ and DC conductors are immersed in the cooling medium to take away the heat in the medium and form a cooling loop through the circulation of the return pipe, which ultimately carries a large current and a small conductor cross-section, achieving high-power and fast charging. The use scenarios of oil-cooled charging cables are generally used in centralized charging stations, large parking lots, hotels, garages and other areas.

Standards and certifications

The basic design complies with IEC62893-4-2

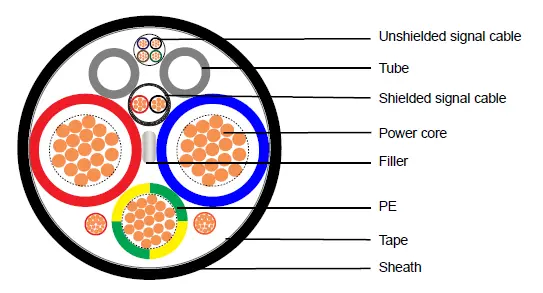

Cable structure

Conductor: Bare or tinned copper, grade 5 to IEC60228.

| Power core | 16mm2~ 150mm2 |

| Control or ignition core | Minimum 0.5mm2 |

| Optional PE conductor | Minimum 25mm2 |

| Optional auxiliary power supply core | 2.5mm2~ 6mm2 |

Insulation: Irradiated cross-linked polyolefin.

Shield (optional): Braided copper wire.

Tube: Irradiated cross-linked polyolefin.

Filler: PP hemp or cotton yarn.

Tape: Non-woven fabric.

Jacket: TPU, black, other colors available on request.

Technical features

Temperature range: - 40º C to + 90º C

Rated voltage: AC 600V/1000V ;DC 1500V

Flame retardant: According to EN 60332-1-2

Minimum bending radius: 6×OD

Dielectric voltage: 3.5kVac/15min. No breakdown

Oil resistance: IRM902, 100°C/168h tensile and elongation>=60%

Cold bending: -40°C/4h no cracks

Thermal shock: 150°C/1h no cracks

Compression resistance: >11KN

Weathering resistance: 720 minutes Xenon arc weatherometer, no cracks

Construction parameters

| Number of cores × cross-sectional area | Nominal thickness of insulation | Nominal thickness of sheath | Maximum outer diameter | Minimum insulation resistance at 90 °C |

| mm² | mm | mm | mm | MΩ km |

| 2×16 | 0.8 | 2.4 | Design structure according to standard or customer requirements | 0.0044 |

| 2×25 | 1.0 | 2.8 | 0.0043 | |

| 2×35 | 1.0 | 3.2 | 0.0037 | |

| 2×50 | 1.1 | 3.6 | 0.0034 | |

| 2×70 | 1.2 | 4.0 | 0.0031 | |

| 2×95 | 1.2 | 4.4 | 0.0028 | |

| 2×120 | 1.3 | 4.8 | 0.0027 | |

| 2×150 | 1.5 | 5.3 | 0.0028 |

Note: 1. Signal line range n = 0-10

2. The number of return pipes is based on customer requirements.

3. The cooling medium is defined by the customer.

PART TWO,Analysis of the competitiveness of core suppliers

1.Polycab India

- Advantageous areas: Building wiring (market share over 35%), low-voltage power cables

- Price strategy: High cost performance, 20-30% lower than imported brands

- Certification: ISI, BIS, IEC 60502

2.RR Kabel

- Featured product: Solar power cable (UL 4703 certified)

- Innovative technology: weather-resistant double-layer insulation (-40℃~120℃)

3.Sterlite Technologies

- High-end market: Submarine water-blocking optical cable (cooperation with Reliance Jio submarine network)

- Technology source: Water-blocking glass fiber yarn produced by patented water-blocking resin coating process

PART THREE,Price sensitivity factors

1.Raw material fluctuations

- Impact of copper prices: Copper cable prices fluctuate by ±15%/quarter (copper price in 2023 is about ₹750/kg)

- Aluminum substitution trend: Aluminum cable price is only 30-40% of copper cable, but BS-7886 certification is required

2.Tariff Policy

- Imported cables: GST 18% + anti-dumping duty 7-15% (additional tariff for cables made in China)

- Local sourcing advice: give priority to suppliers with the "Make in India" label

PART FOUR,Procurement strategy recommendations

1.Bulk Purchase Discounts

- 5-8% discount for orders over 10,000 meters (like Polycab's tiered pricing policy)

2.Authentication and Verification

- Required certification: ISI mark (mandatory), ISO 9001 (quality system)

- High-end scenarios: Prioritize products with IEC 60754 (low smoke and halogen-free) certification

- Logistics Optimization

- Regional distribution centers: Mumbai (west coast), Chennai (South India) warehouse delivery price is 10-15% lower

PART FIVE,Risk Warning

1.Identification of counterfeit products

- Counterfeit brands: Beware of variant trademarks such as "P0lycab" (the number 0 replaces the letter o)

- Verified channels: filter suppliers by Indiamart's "Verified Plus" label

2.Delivery delay

- Rainy season impact: Mumbai Port is congested from June to September, it is recommended to place orders 45 days in advance

Through this analysis, we can quickly identify high-demand categories and compliant suppliers in the Indian cable market, and optimize procurement costs by combining tariff policies and localized production advantages. We need to focus on growth areas such as water-blocking optical cables and solar cables (annual growth rate of 12-18%).