Tapping machines for high-speed copper cables

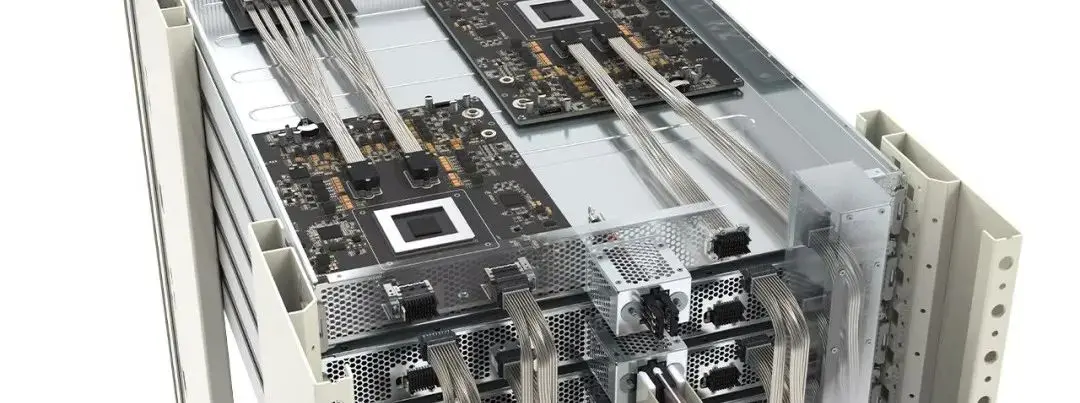

The AI wave has driven a surge in data processing, driving an increase in demand for cloud computing power. The demand for high-speed connections within data centers has increased significantly, requiring interconnection channels with greater carrying capacity as support.

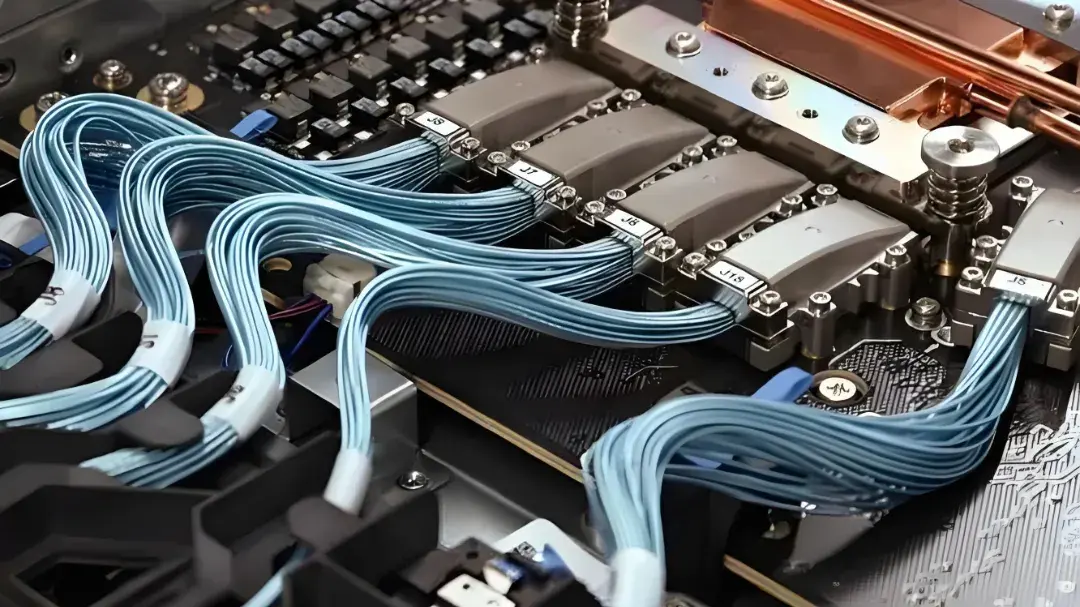

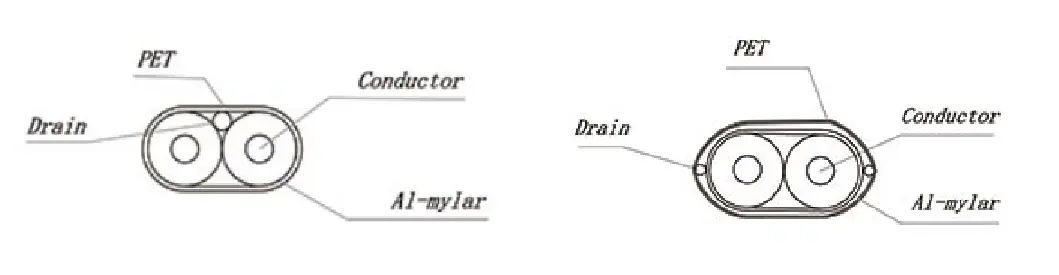

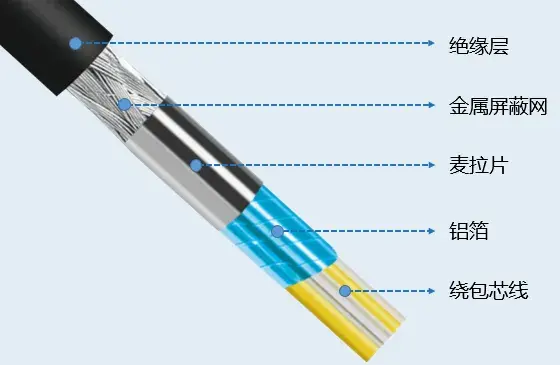

High-speed cables are generally used to achieve short-distance high-speed interconnection communications. They basically use silver-plated conductors and foamed insulated core wires, which have excellent attenuation performance and low delay. They can transmit signals correctly while increasing the transmission speed. They also use a parallel pair-wound cable shielding structure, which has good shielding effect and low delay difference performance, enabling the wire to have high-frequency broadband transmission and excellent anti-interference performance.

The function of the taping machine is to allow the tape to be tightly wound around the copper wire according to the set pitch during the cable production process to improve the performance of the cable. The technical difficulty lies in controlling the combined use of taping, pulling and unwinding to ensure that the tape is evenly and tightly wound around the cable.

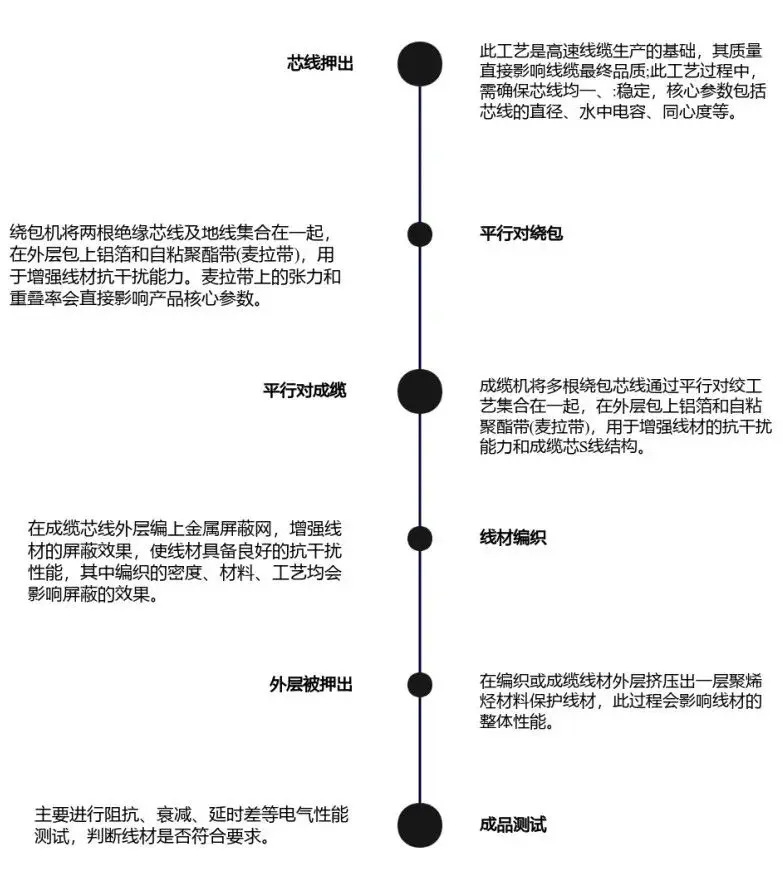

The production process of high-speed cables is mainly divided into six steps:

Core winding process:

1) Paying off the wire with constant tension. Ensure the stretching amount of the wire;

2) Parallel winding. When the core wires are parallel, wrap the two core wires and the ground wire evenly on the outer layer of the four wires with aluminum foil, and use Mylar sheet to evenly wrap it on the outer layer of the core wire according to a specific process;

3) Heating in the oven. The Mylar sheet shrinks when heated, making it tightly wrap around the core wire;

4) Wire diameter measurement. Check whether the line diameter error meets the process standards;

5) Laser coding. Spraying the core line mark is convenient for later use

6) Arrange the wires evenly to avoid interweaving of wires and affecting quality.

As a combination standard of group standards such as "224Gbps high-speed backplane transmission symmetrical cable" and "224Gbps high-speed direct-connect copper cable", "Taping Machine for High-Speed Transmission Cable" focuses on standardizing the manufacturing process and equipment performance of high-speed transmission cables, filling the long-standing standard gap in the field of high-speed transmission Cable Manufacturing Equipment, and effectively assisting the precise adaptation and close connection of manufacturing equipment and upstream and downstream industrial chains. For manufacturers, this standard will play a positive role in optimizing product manufacturing processes, strengthening product reliability, reducing supply chain costs, and improving overall operational efficiency, making products more in line with market demand and laying a solid foundation for high-quality development of the industry.