Production process of aluminum magnesium alloy wire by horizontal continuous casting method

(Horizontal continuous casting aluminum-magnesium alloy wire production process)

6-12mm aluminum rod horizontal continuous casting machine

3.00mm aluminum-magnesium alloy rod

1.07 aluminum-magnesium alloy wire

0.12mm aluminum-magnesium alloy wire

1. Process flow

Aluminum ingot, magnesium ingot -->natural gas aluminum melting furnace -->Φ 8.5 rod (magnesium aluminum rod horizontal continuous caster) -->Φ 6.5 bright rod (skin grinder) -->Φ 3.0 rod (single die Pulley Wire Drawing Machine , a nnealing) -->Φ 1.17 wire ( three die Pulley Wire Drawing Machine , a annealing) -->Φ 0.12 fine wire (28 mode small wire drawing machine, annealing) -->inspection and packaging

2. Process description

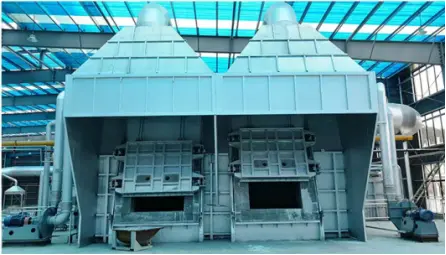

① Aluminum melting: Place purchased aluminum and magnesium ingots in a melting furnace according to product requirements in a certain proportion and heat them to 700 ℃ for melting treatment. The melting furnace uses natural gas heating.

Small aluminum melting furnace

Regenerative natural gas aluminum melting furnace

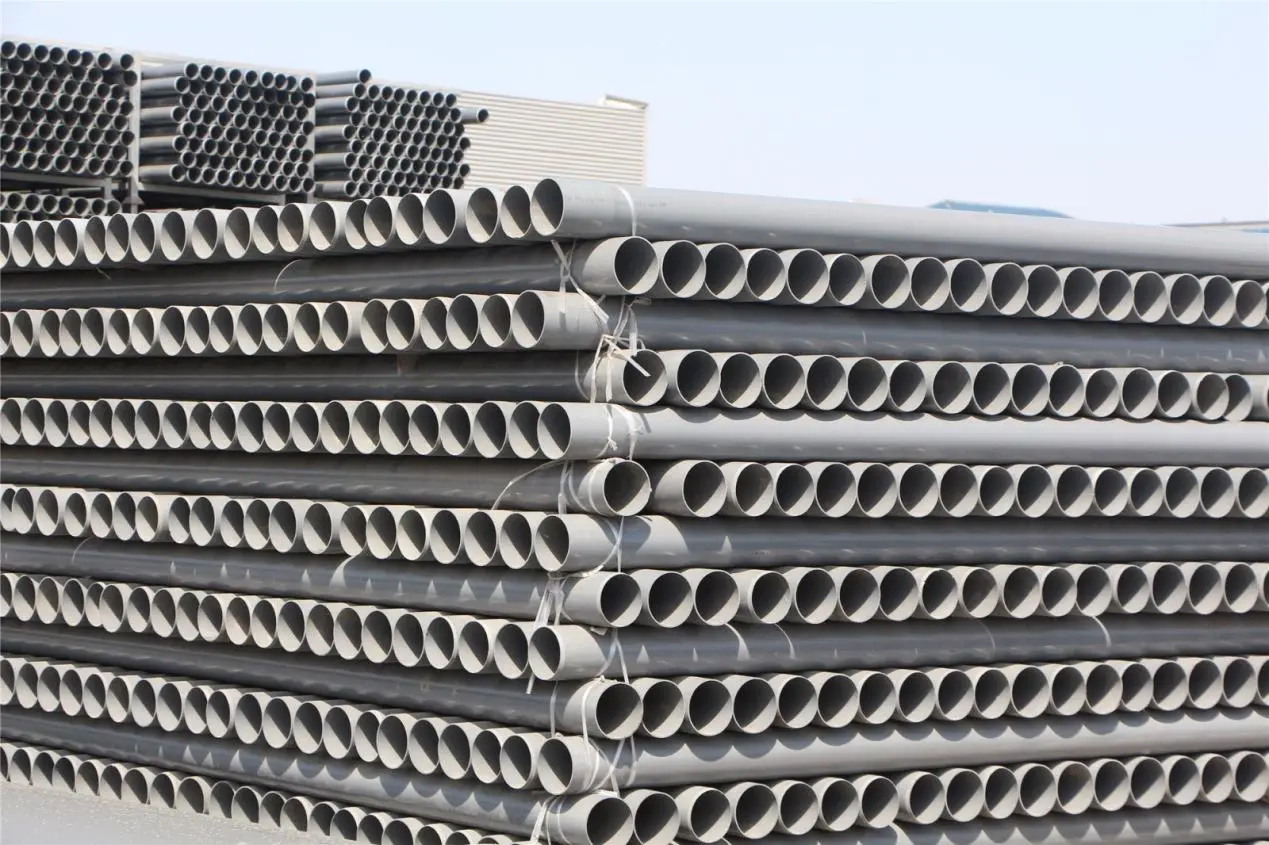

② Casting rod: According to the different specifications of the product, the melted aluminum and magnesium alloys are cast and drawn into the required wire diameter specifications by a horizontal continuous casting unit equipment. The casting and drawing process uses water cooling (indirect cooling), and the diameter of the product after casting and drawing is about 8.5cm. The circulating cooling water is used without discharge.

Horizontal continuous casting machine for copper rod and aluminum rod

Horizontal continuous casting aluminum rod puller and winder

③ Grinding: The metal rod behind the pull rod is roughened using a roughening machine, which requires the use of rubber oil. Over time, the rubber oil may accumulate metal deposits and needs to be replaced regularly. The diameter of the wire rod after roughening is about 6.5cm;

Polishing and dehairing machine

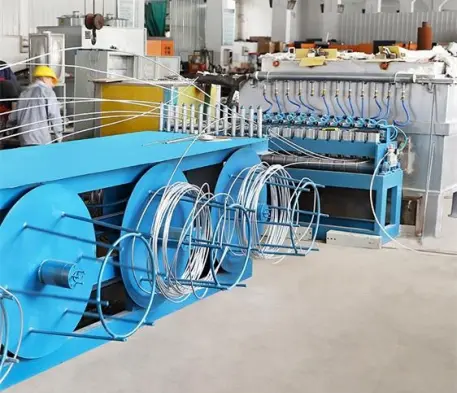

④ Annealing and large wire drawing: Place the wire rod after roughening into an annealing furnace for tempering to reduce product hardness, eliminate residual stress, and reduce deformation; The annealed products are drawn using a water tank drawing machine. The water tank drawing machine is a small continuous production equipment composed of multiple drawing heads. Through step-by-step drawing, the drawing heads are placed in the water tank, and finally the alloy wire is pulled to the required specifications. oil, mainly for lubrication and cooling purposes. The engine oil will precipitate metal after prolonged use and needs to be replaced regularly. This process requires two steps according to product requirements. The wire diameter after the first annealing and drawing is about 2.9cm, and the wire diameter after the second annealing and drawing is about 1.17cm.

Single-mode pulley wire drawing machine

Continuous three-die pulley wire drawing machine

Wire Pit Annealing Furnace

⑤ Annealing and high-speed wire drawing: Some products require finer wire diameters, so products that have undergone large wire drawing are annealed and then subjected to high-speed wire drawing using a high-speed wire drawing machine. High speed wire drawing requires the use of high-speed wire drawing oil, which can cause metal precipitation over time and needs to be replaced regularly. Products with finer diameters can be obtained through high-speed wire drawing, mainly including diameters of 0.12cm, 0.15cm, and 0.16cm; After high-speed wire drawing, it is the finished product.

28-die aluminum-magnesium alloy small wire drawing machine

Continuous annealing machine

⑥ Annealing and rewinding: The welding wire after high-speed drawing is rewinding using a rewinding machine, which requires the use of lubricating oil to maintain the lubricity of the product.

Wire box annealing furnace

Multi-head rewinding machine

List of Main Raw and Auxiliary Material Consumption

Annual production of 5000 tons of aluminum magnesium alloy wires:

| Serial number | Material Name | Actual consumption |

| 1 | aluminum ingots | 4578t/a |

| 2 | Master Alloy | 141t/a |

| 3 | magnesium ingots | 219t/a |

| 4 | rubber oil | 3.5t/a |

| 5 | engine oil | 15t/a |

| 6 | High-speed wire drawing oil | 27t/a |

| 7 | White oil | 11t/a |

| 8 | emulsion | 1.8t/a |

| 9 | Deslagging agent | 4.9t/a |

4. List of Main Production Equipment

Annual production of 5000 tons of aluminum magnesium alloy wires:

| Serial number | Device Name | Actual quantity (units) |

| 1 | Natural gas aluminum melting furnace | 1 |

| 2 | Test furnace | 1 |

| 3 | Roughening and polishing machine | 5 |

| 4 | tempering furnace | 3 |

| 5 | wire drawing machine | 15 |

| 6 | 55 | |

| 7 | Parallel machine | 25 |

| 8 | Water tank wire drawing machine | 10 |

| 9 | Large wire peeling machine | 12 |

| 10 | Intermediate drawing machine | 6 |

| 11 | Rewinding Machine | 4 |