Indonesia's hot-selling cable varieties and matching second-hand cable machinery

1. Analysis of hot-selling cable varieties in Indonesia

Indonesia's infrastructure and industrial expansion have boosted demand for cables, with the following varieties experiencing strong demand and supply:

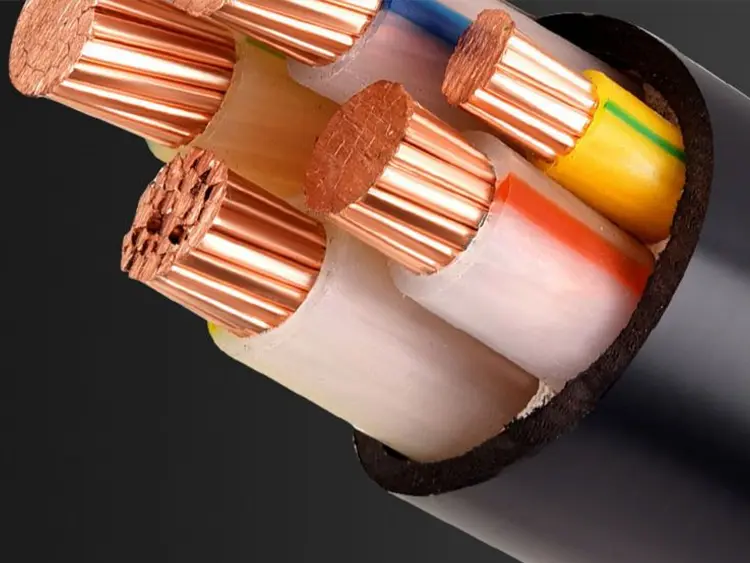

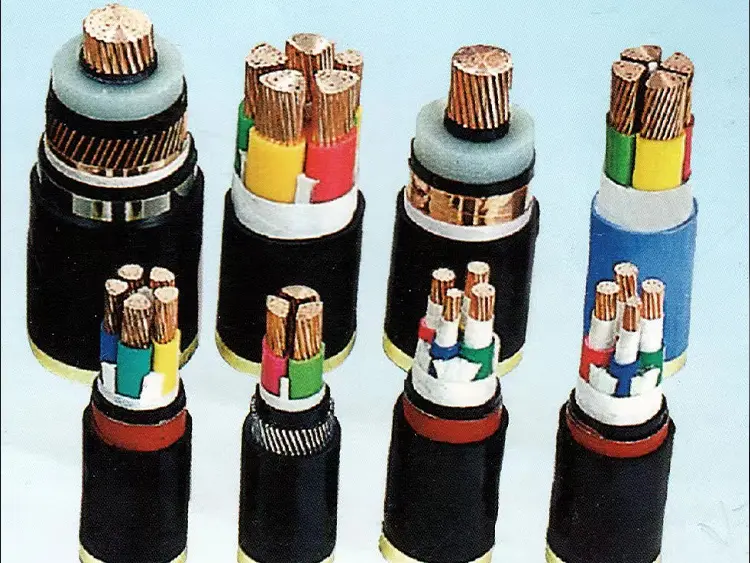

1. Copper Conductor Power Cables

- Demand driven: New energy projects (photovoltaic power stations, wind power) and power grid upgrades, applicable voltage levels 1kV-35kV.

- Technical features: XLPE insulation (high temperature resistant to 90°C), flame retardant sheath, common cross-section 4mm²–95mm².

- Market data: Ranked second in the market popularity list (demand index 4.24), with significant demand for similar photovoltaic projects in Indonesia.

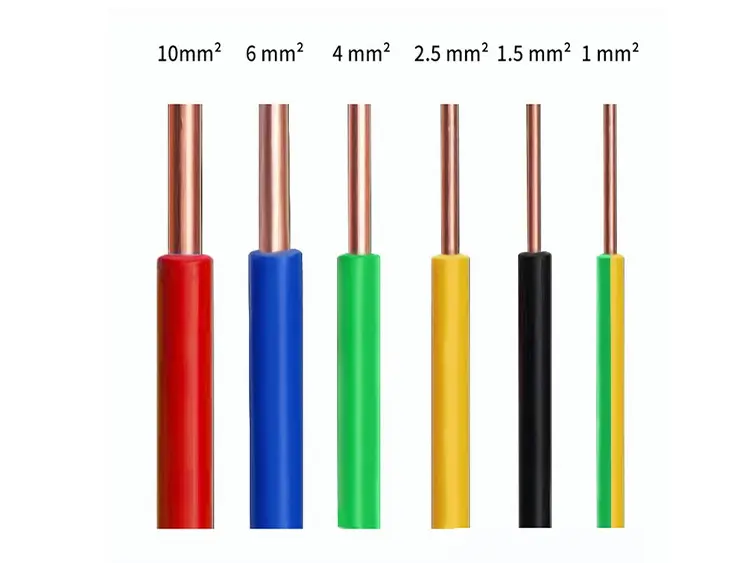

2. Insulated Electrical Wires

- Application scenarios: residential electrical wiring, low-voltage electrical appliance connections, mainly PVC insulation.

- Hot-selling specifications: 1.5mm²–6mm² single-core/multi-strand wire, home installation cost is about 10 yuan/meter.

3. Welding Cables

- Industrial demand: essential for shipbuilding and metal processing plants, carrying current up to 800A, requiring super flexibility and bending resistance.

- Mainstream products: 120mm² rubber sheathed cable (-20℃~90℃ temperature resistance), OEM quotation $0.8–$23.6/meter.

4. Reeling Cables

- Mechanical accessories: dedicated to port cranes and conveying equipment, the German brand LAPPKABEL NSHTOU series dominates the high-end market.

- Performance requirements: Neoprene sheath (flame retardant, oil resistant), tensile braided layer, specifications such as 4G25, 7G1.5, etc.

5. Aluminum-clad steel optical fiber composite overhead wire (OPGW)

- Infrastructure needs: power grid and communication integration projects. Indonesia's import volume will increase by 15% year-on-year in 2024.

- Trade dynamics: China is the main supplier, while Russia and India are also increasing their exports.

2. Recommendation of suitable second-hand cable machinery

Indonesian SMEs tend to purchase cost-effective second-hand equipment. The following machines are highly compatible with popular products:

1. Copper cable/insulated wire production equipment

①Second -hand extrusion production line:

- Applicable products: PVC insulated wires, low voltage power cables.

- Recommended model: Cable and wire production line (made in Guangdong), including extruder, cooling tank, and take-up rack, unit price starts from $3,000.

- Advantages: Supports 4mm²–70mm² cross-sections and is compatible with double-layer extrusion of insulation and sheath.

② Wire Stranding Machine:

- Applicable products: multi-strand wires, twisted conductors.

- Technical parameters: Processing copper wire diameter 0.1mm-3.0mm, rotation speed 1,500rpm.

2. Special cable machinery

① Cable drum complete equipment:

- Core equipment: twisting machine + cabling machine + braid coating device.

- Second-hand source: German Demag/Vahle production line, supporting neoprene sheath process.

Cable drum design process

Conductor: Polyurethane reel cable The cable is made of multi-strand finely twisted oxygen-free copper wire

Insulation: Special mixed PVC insulation

Color: ≤0.5mm² color identification, brown, black, blue, purple, pink, orange >0.5mm² Black numbers and white numbers, 3 cores or more with yellow-green wire

Inner sheath: Polyurethane cable can add inner sheath according to customer's actual use

Lining layer: Special non-woven fabric wrapped cushioning

Reinforcement: Center steel wire rope for tension resistance/multi-strand jute rope for filling (optional)

Shield: Tinned copper mesh braided shield, density above 85%

Sheath: Nitrile elastomer /imported polyurethane material, color can be selected by yourself.

②OPGW composite production line:

- Function: Aluminum clad steel wire + optical fiber unit synchronous composite twisting.

- Supply: Equipment with a production capacity below 35mm² is common in the Chinese second-hand market.

3. Detection and auxiliary equipment

①High voltage tester:

- Used for: Verifying the insulation strength of power cables (0–30kV).

②Marking inkjet printer:

- Compatibility: Supports erasure-resistant printing on the cable surface.

3. Suggestions for Indonesian Market Development

1. Channel strategy

- B2B platform: Push keywords such as "XLPE cable for photovoltaics" and "rubber welding cable" on Indotrading/Alibaba, and highlight UL/VDE certification.

- Local cooperation: Cooperate with Indonesian electromechanical installers (accounting for 60% of cable users) to provide construction + product packaging services.

2. Equipment procurement cost control

- Second-hand machinery is preferred to be from Guangdong, China (high cost performance, easy to obtain repair parts), such as $3,000-level stranding machines.

- Avoid old European equipment (maintenance costs can be up to 40% of new equipment).

Comparison table of popular cable varieties and matching equipment

Cable Type | Core application scenarios | Adaptation for second-hand equipment | Key parameters/cost |

Copper core power cable | Photovoltaic power stations and power grid upgrades | Extrusion Line | From $3,000, supports 4-70mm² |

Insulated wire | Residential wiring, low voltage electrical appliances | Wire stranding machine + extruder combination | 1.5-6mm², installation cost ~10 yuan/m |

Welding Cables | Shipbuilding, metal processing | Rubber sheath extruder | 120mm² price $0.8-23.6/meter |

Reeling Cables | Port cranes and conveying equipment | Demag/Vahle units | Neoprene sheath process |

Optical fiber composite overhead wire | Power grid communication project | OPGW composite stranding production line | Production capacity below 35mm² |