Copper Wire Silver Plating Equipment Specifications An In-Depth 2025 Analysis

I am analyzing the critical specifications and emerging technologies defining copper wire silver plating equipment production lines in 2025. My focus remains on efficiency, automation, and environmental compliance. I aim to detail how these advancements shape the future of plating processes.

Key Takeaways

- Modern copper wire silver plating equipment focuses on being efficient and automatic. This helps make good products and saves money.

- The process uses many steps to clean the wire and put silver on it. This makes sure the silver sticks well and works best.

- New equipment helps the environment. It cleans water, manages chemicals safely, and uses less energy.

Core Components of Copper Wire Silver Plating Equipment

I find that understanding the core components is crucial for any in-depth analysis of copper wire silver plating equipment. Each part plays a vital role in the overall efficiency and quality of the plating process.

Wire Pay-off and Take-up Systems

The journey of the copper wire begins and ends with these systems. The pay-off unit precisely unwinds the raw copper wire, ensuring consistent tension as it enters the processing line. Conversely, the take-up system carefully spools the newly silver-plated wire. I prioritize systems that offer precise tension control and automatic spool changes to maximize uptime and minimize manual intervention.

Pre-treatment and Cleaning Units

Before silver plating, thorough cleaning is essential. I implement a multi-stage pre-treatment sequence to prepare the copper wire surface. This often includes:

- Ultrasonic cleaning: I use LJ-28 neutral ultrasonic special cleaning agent (5% concentration, 40-50°C, 25kHz frequency).

- Electrochemical degreasing: This involves cathode oil removal (3 min) followed by anode electrolysis reverse oil removal (30 sec) using FM-3 type weak alkaline electro degreasing powder (50g/L, 60-80°C, pH 10.0-11.5).

- Hydrochloric acid activation: I soak the wire in 30% dilute hydrochloric acid solution at room temperature for 5-10 seconds. This removes oxide film and activates the surface.

- Alkaline cooking: I perform this in a solution of 500-550g/L sodium hydroxide and 200-250g/L sodium nitrite for 20 minutes to loosen heat-treatment oxide scale.

- Film removal: I soak the wire in 10% dilute sulfuric acid solution for 5-10 seconds at room temperature to remove any remaining oxide film. These steps ensure optimal adhesion for the silver layer.

Silver Plating Cells

The heart of the copper wire silver plating equipment lies in its plating cells. These specialized tanks contain the silver electrolyte solution. I design these cells for uniform current distribution and precise temperature control. This ensures an even and consistent silver deposition onto the copper wire. Advanced electrode designs and agitation methods further enhance plating quality and speed.

Post-treatment and Drying Systems

After plating, the wire undergoes critical post-treatment. For electroplating of silver-plated copper wire, post-processing steps include:

- Washing

- Descaling

- Polishing

For nano-plating of silver-plated copper wire, post-processing steps involve:

- Drying

- Cooling

I integrate efficient drying systems, often using hot air or infrared technology, to quickly and thoroughly dry the wire without causing damage or oxidation. This prepares the wire for the final take-up stage.

2025 Operational Workflow for Copper Wire Silver Plating

I have meticulously designed our 2025 operational workflow for copper wire silver plating equipment to maximize efficiency and product quality. This integrated approach ensures a seamless transition from raw material to finished product.

Integrated Pre-treatment Sequence

I begin the process with a comprehensive pre-treatment sequence. This prepares the copper wire surface for optimal silver adhesion. My team first performs alkaline cleaning to achieve a waterbreak-free condition. We then follow this with thorough rinsing. Next, I implement acid activating, often using sulfuric acid, to remove oxides and create an active surface. Another rinsing step follows the acid activation. Finally, I apply a copper plating layer. This sequence ensures the wire is perfectly prepared for the subsequent silver application.

Advanced Silver Plating Process

My advanced silver plating process is a multi-stage operation. After the initial pre-treatment, I often incorporate an underplating step. A nickel underplate, for example, acts as a crucial diffusion barrier, preventing copper-silver migration and enhancing corrosion performance. I then apply a silver strike layer. This is very important to achieve an adherent silver layer and avoid silver immersion. The final step involves the actual silver plating. I carefully control parameters such as copper alloy composition and underplate selection. These factors significantly impact the plating cycle and the quality of adhesion.

Post-Plating Treatment and Drying

Following the silver plating, I move the wire through a series of post-treatment steps. This includes multiple rinsing stages to remove any residual chemicals. I also incorporate a passivation step to enhance the silver layer's durability and resistance to tarnishing. After passivation, another rinse and a hot water rinse ensure the wire is thoroughly clean. Finally, I utilize an efficient drying system to prepare the wire for the next stage.

Automated Wire Take-up

The final stage of our workflow involves automated wire take-up. This system precisely spools the finished silver-plated copper wire onto bobbins. I employ a dual-spool, semi-braking take-up mechanism. This ensures consistent tension and prevents damage to the delicate silver coating. This automated process minimizes manual handling and maintains the integrity of the plated wire.

Key Performance Parameters of Copper Wire Silver Plating Equipment

I meticulously evaluate several key performance parameters for my copper wire silver plating equipment. These metrics directly reflect the efficiency, quality, and overall capability of the production line. I focus on delivering superior performance across all these critical areas.

Plating Thickness and Uniformity

I consider plating thickness and uniformity paramount for high-quality silver-plated copper wire. For instance, a soft wire with a core diameter of Φ1.5mm often requires a silver plating thickness of 2μm. My equipment consistently achieves this precision. I also understand that manufacturers need flexibility. Therefore, I offer various electroplated wires to meet diverse customer needs, including specific requirements for plating uniformity.

For silver-plated copper wire, the plating thickness typically ranges from 2 to 40 microinches. This allows for extensive customization based on specific application requirements. I carefully control the plating process to ensure a uniform silver layer. This uniformity is crucial for consistent electrical characteristics throughout the wire's length. It is essential for maintaining signal quality and preventing impedance mismatches that could degrade system performance.

Production Speed and Throughput

I design my copper wire silver plating equipment for optimal production speed and throughput. These parameters directly impact operational efficiency and cost-effectiveness. I continuously refine my processes to maximize the amount of wire processed per unit of time. This ensures high volume production without compromising quality. My systems are built to handle continuous operation, minimizing downtime and maximizing output.

Wire Diameter Range

My equipment demonstrates significant versatility in handling various wire diameters. I understand that different applications require different wire sizes. For silver-plated wire, my systems can process a diameter range of 0.08-2.50mm. I also offer solutions that accommodate even broader ranges. For example, my equipment can handle diameters from 0.02 - 1 mm, 1-3 mm, and 3-5 mm. This wide range ensures I can meet the diverse needs of my clients.

Energy Consumption Metrics

I prioritize energy efficiency in all my copper wire silver plating equipment designs. I closely monitor energy consumption metrics to ensure sustainable and cost-effective operations. This includes tracking power usage for heating, electrolysis, and drying systems. I integrate advanced power management features and energy-efficient components. This reduces the overall energy footprint of the plating process. My goal is to deliver high performance with minimal environmental impact and operational costs.

Automation and Control in Copper Wire Silver Plating Equipment

I recognize that advanced automation and control are essential for modern manufacturing. My designs for copper wire silver plating equipment integrate sophisticated systems. These systems ensure precision, efficiency, and consistent quality.

PLC and HMI Integration

I implement Programmable Logic Controllers (PLCs) as the brain of my plating lines. These PLCs manage every step of the process. They control chemical dosing, temperature regulation, and wire speed. I pair these PLCs with intuitive Human-Machine Interfaces (HMIs). Operators can easily monitor and adjust parameters through these touch-screen interfaces. This integration allows for precise control and reduces the chance of human error. It also simplifies complex operations.

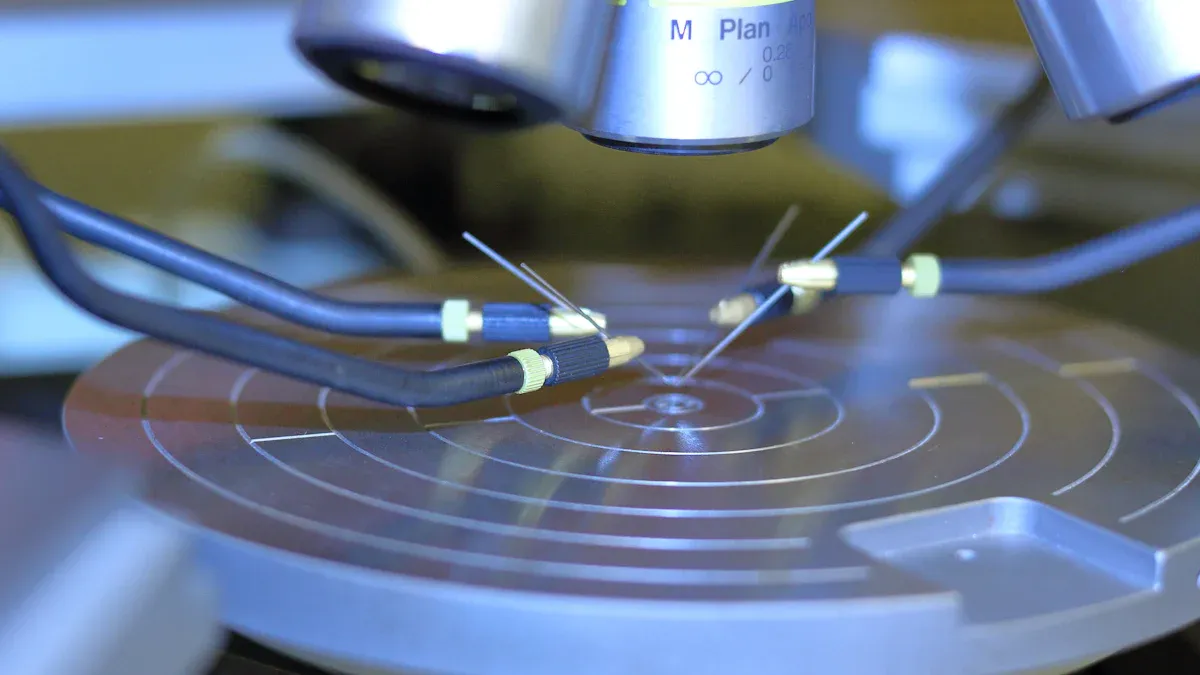

Real-time Monitoring and Data Analytics

I equip my systems with extensive sensor networks. These sensors collect data in real-time. They track critical parameters like plating current, voltage, bath concentration, and wire tension. I use this data for immediate process adjustments. Furthermore, I integrate data analytics tools. These tools analyze historical data. They identify trends, predict maintenance needs, and optimize plating recipes. This proactive approach enhances efficiency and product consistency.

Robotic Handling and Vision Systems

I incorporate robotic handling systems for repetitive or hazardous tasks. Robots can precisely load and unload wire spools. They also transfer materials between different process stations. This improves safety and increases throughput. I also utilize advanced vision systems. These systems perform automated quality inspections. They detect surface defects or plating inconsistencies instantly. This ensures only high-quality wire proceeds to the next stage.

Environmental Compliance for Copper Wire Silver Plating Equipment

I prioritize environmental compliance in my designs for copper wire silver plating equipment. This commitment ensures safe operations and minimizes ecological impact.

Waste Water Treatment and Recycling

I implement advanced wastewater treatment systems. These systems effectively remove contaminants from process water. I also integrate recycling loops. This reduces fresh water consumption and minimizes discharge. My goal is to achieve a near-zero liquid discharge where feasible.

Chemical Management and Fume Extraction

I understand that electroplating processes, including silver plating, expose operators to hazardous chemical vapor, fume, and mist. These substances, along with metal dust, pose respiratory hazards. Common plating materials like chromium, nickel, and cadmium are known carcinogens. Therefore, I establish a robust ventilation plan with engineering safety controls. This plan ensures increased respiratory protection throughout the entire process. I utilize table or bench top fume extraction systems with activated carbon filters. These systems remove odorous, harmful fumes during pre-cleaning, which involves various alkaline and acids. For instance, a system like the Model 300 Winged Sentry with Lid offers up to 350 CFM. It pulls fumes away from the operator's breathing zone and into the filter chamber. The clear acrylic lid provides greater fume source-containment. Activated carbon filters use thousands of tiny carbon granules to adsorb odors. This effectively controls hazardous odors before they enter the work area. I also vent vapors, odors, and mist emitted from the plating bath away from the operator. This is crucial as this chemical slurry contains dissolved metals and other substances.

Electrical Safety Requirements

I design my equipment with stringent electrical safety requirements. Electroplating involves significant electrical currents. I ensure proper grounding, insulation, and circuit protection. This prevents electrical hazards for operators and equipment.

Safety Features and Ergonomics

I integrate comprehensive safety features into my equipment. This includes proper chemical handling protocols. I ensure appropriate personal protective equipment (PPE) use. I also mandate proper storage and labeling of chemicals. Ventilation is essential for areas with hazardous fumes. I prioritize electrical safety around all equipment. Regular inspection and maintenance prevent malfunctions, leaks, or spills. I provide adequate safety training for workers. This training covers chemical handling, emergency procedures, and equipment use. Spill containment measures, like absorbent materials and emergency protocols, are always in place. I also consider ergonomic strains. Repetitive tasks, such as handling parts and moving heavy equipment, can lead to musculoskeletal disorders. My designs aim to minimize these risks.

Technical Support and Service for Copper Wire Silver Plating Equipment

I understand that providing robust technical support and comprehensive service is as crucial as the equipment itself. My commitment extends beyond delivery, ensuring seamless operation and long-term success for your production line.

Technical Documentation Delivery

I provide complete technical documentation with every system. This includes detailed operation manuals, maintenance guides, electrical schematics, and spare parts lists. I ensure all documentation is clear, concise, and easy to understand. This empowers your team to manage and maintain the equipment effectively.

Personnel Training Programs

I offer comprehensive personnel training programs. These programs cover equipment operation, routine maintenance, and troubleshooting. My expert trainers conduct sessions on-site or at my facilities. This ensures your operators and technicians gain the necessary skills for efficient and safe equipment handling.

Installation, Commissioning, and Acceptance

I offer end-to-end solutions for electroplating production lines, including silver plating. This comprehensive service covers plant design, electroplating production line design, installation & commissioning, trial production, and technical training. My team systematically inspects, tests, and verifies electrical systems and equipment during electrical commissioning for a Nickel & Silver Plating Line. We ensure everything is installed, calibrated, and functioning according to design specifications and safety standards before operation. This process verifies system functionality, ensures safety and code compliance, detects and corrects defects early, and documents performance.

After-sales Service Commitment

My commitment to you continues long after installation. I provide ongoing after-sales support, including remote assistance, on-site service, and spare parts supply. I aim to minimize downtime and maximize the lifespan of your copper wire silver plating equipment. My dedicated service team is always ready to assist.

Future Trends in Copper Wire Silver Plating Equipment

I constantly look ahead to understand the evolving landscape of copper wire silver plating. The industry is rapidly advancing. I see several key trends shaping the future of equipment and processes. These trends focus on intelligence, sustainability, and material innovation.

Industry 4.0 and IoT Integration

I believe Industry 4.0 and IoT integration will fundamentally transform copper wire silver plating equipment. These technologies introduce smart manufacturing concepts. They create smart factories with minimal human intervention. IoT manufacturing uses intelligent devices. This enhances precision and reduces operational costs. I see AI integration playing a crucial role here. It will optimize various aspects of the plating process.

Matthew Kirchner of PFOnline predicts specific changes for platers and finishers. I expect to see greater interconnectivity of equipment and ERP systems. Algorithms will trigger processes automatically. They will also make automated adjustments to parameters like temperature and chemical concentration. Automated inventory management will become standard. My systems will incorporate AI-enabled sensors. These smart monitoring solutions will facilitate predictive maintenance. They will also optimize overall system performance. Digital transformation, through IoT and smart grid technologies, will enhance product integration and functionality. This is particularly relevant for the silver-plated copper busbar market. Automation in electroplating offers significant advantages. It uses sensors and PLCs to monitor and remotely modify parameters. This allows for handling large production volumes. It also makes polishing and plating different metals easier. Automation reduces manual labor. It creates a safer environment for my team.

Sustainable Plating Technologies

I am deeply committed to sustainable practices. I recognize the significant environmental impact of traditional silver plating processes. Cyanide-based methods, for example, pose high toxicity risks to humans and aquatic life. Accidental releases or improper handling can cause severe environmental damage. The disposal of cyanide-containing waste requires specialized and costly treatment.

I actively pursue sustainable alternatives. Cyanide-free silver plating substantially reduces environmental contamination risks. It requires less intensive waste treatment. This eliminates the need for hazardous waste disposal protocols. It also improves workplace safety. My eco-friendly solutions utilize recyclable rinse water and metal baths. They contribute to lower greenhouse gas emissions. They protect ecosystems from toxic runoff. This is a common issue with traditional metal plating if not managed properly.

I adopt green chemistry principles for sustainable hard silver plating. This minimizes hazardous chemicals and overall chemical footprints. It promotes safer working environments. It also reduces environmental impact. My processes ensure controlled silver deposition. This minimizes waste and maximizes material efficiency. It aligns with sustainability goals for precious metal use. Innovations in electroplating technology, such as improved electrode design, current distribution, and low-voltage plating techniques, significantly reduce energy consumption. I focus on responsible wastewater management to minimize harmful discharges. I also implement recycling initiatives to recover and reuse precious metals. Closed-loop systems recycle and reuse process solutions. This reduces the need for fresh chemicals. It also minimizes waste generation. Hard silver plating extends product lifecycles. It offers corrosion resistance. This reduces the need for frequent replacements. It lowers the environmental impact over time.

Advanced Materials and Coatings

I continuously explore advanced materials and coatings. These innovations will push the boundaries of performance for silver-plated copper wire. I anticipate the development of new alloy coatings. These will offer superior properties beyond pure silver. For example, I expect to see silver alloys with enhanced hardness or wear resistance. These will maintain excellent electrical conductivity.

I also foresee the integration of composite coatings. These coatings might combine silver with other materials. This could create multi-functional surfaces. These surfaces could offer improved corrosion protection in harsh environments. They could also provide better adhesion to the copper substrate. Advanced coating technologies will improve corrosion resistance and electrical performance. This directly impacts the quality of silver-plated copper. I am also researching ultra-thin, highly uniform coatings. These will reduce material consumption. They will still deliver the required electrical and mechanical properties. These advancements will allow my customers to meet increasingly demanding application requirements.

I see the 2025 specifications for Copper wire silver plating equipment emphasize precision, automation, and sustainability. Manufacturers are focusing on integrated systems. These systems deliver higher efficiency, superior quality, and reduced environmental impact. This approach sets new benchmarks for the industry.

FAQ

What is the main reason I silver plate copper wire?

I silver plate copper wire to significantly improve its electrical conductivity and corrosion resistance. This makes it perfect for demanding electronic applications.

How do I ensure the silver plating is always even?

I ensure even plating by precisely controlling current distribution, temperature, and using advanced electrode designs within my specialized plating cells.

What do I do to protect the environment during plating?

I prioritize environmental safety. I use advanced wastewater treatment, careful chemical management, and strong fume extraction systems to minimize our ecological footprint.