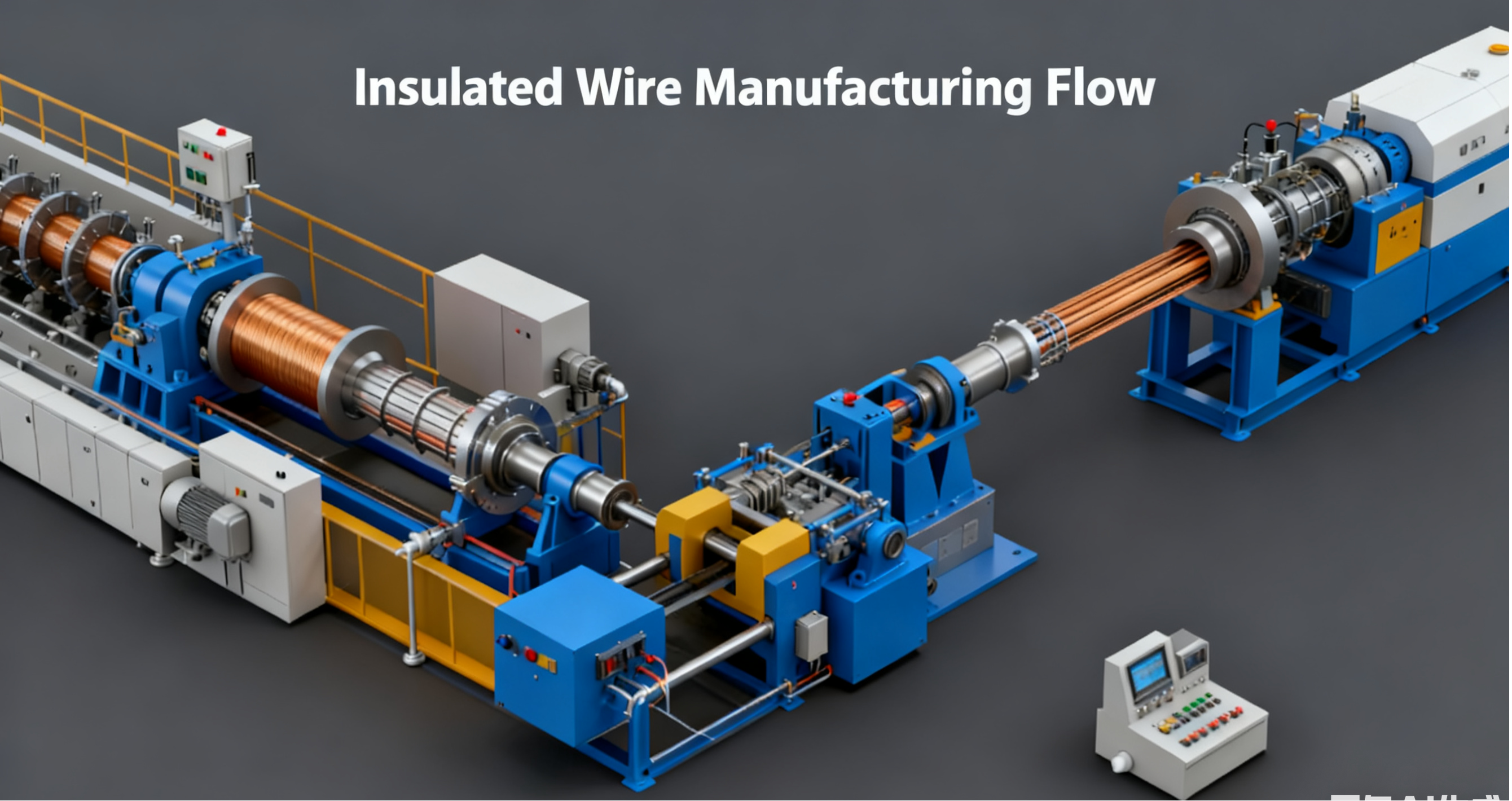

GT-65MM+35MM HIGH SPEED TANDEM LINE

TECHNICAL PARAMETER

Technical Parameter

Items |

Details |

Wire Inlet Diameter |

1.8MM Hard(Soft)copper wire (According to Finished wire dia) |

Finished Wire Flange |

0.40-0.90MM |

Wire Diameter after Insulation |

0.40 - 0.90MM |

Copper Wire Outside Diameter Deviation (As per online laser measurement value) |

±0.001mm |

Copper Wire Ovality (As per online laser measurement value) |

±0.001mm |

Copper Wire Ductility |

15 - 30% |

Outer Diameter Deviation for LAN Cable (As per online laser measurement value) |

±0.006 within AVG |

Outer Diameter Deviation for Insulated Communication Cable (As per online laser measurement value) |

±0.015 within AVG |

LAN Cable Concentricity |

>96% |

Concentricity Calculation Formula |

f = 1 - (e1 - e2)/(e1 + e2), e1 = Max.Thickness, e2 = Min.thickness |

Average control value for Single wire capacitance (As per online measurement value) |

±1.0 - 1.5pf/m within AVG |

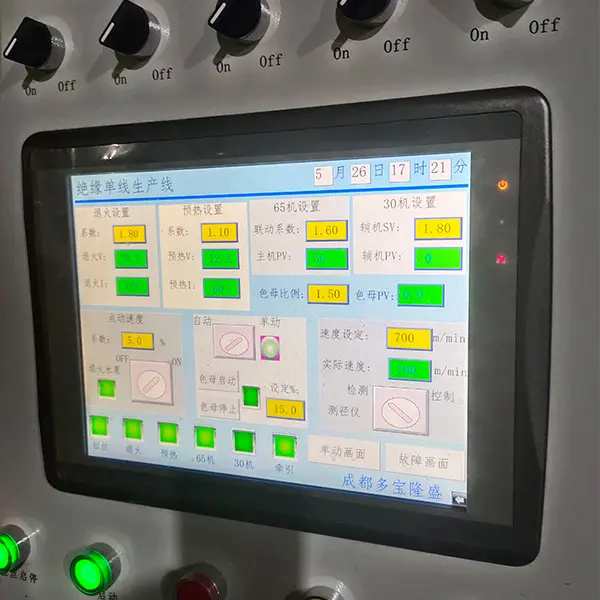

Linear Speed |

Max 2000m/min, 33.3 m/Sec, stable at 1500M/Min (In condition continuous production per month, 24hrs per day), 1350 - 1450M/min is the best |

Applicable Insulation Material |

PE, PP, PVC (Add extrusion material) |

Copper Wire |

1.8MM Hard(Soft)copper wire (According to Finished wire dia) |

Insulation Outside Diameter |

0.5 ~ 2.5 mm |

Copper Wire Extension Rate |

Can be adjusted to 22 ± 2% during production |

MECHANICAL SPECIFICATION

Screw Rotation Speed

description2

Main Extruder: |

20-110RPM |

Sub Extruder: |

20-80RPM |

Screw Extruding Capacity |

|

Main Extruder |

HDPE 120KG/Hr |

Co-extruder |

HDPE 40KG/Hr |

Production Line Speed |

Max.1500M/min |

Equipment Surface Coating |

|

Mechanical Parts |

As per customer’s request |

Rotation Parts |

As per customer’s request |

Safety Door |

As per customer’s request |

Electric Control Box |

As per customer’s request |

Control Box Base |

As per customer’s request |

Production Line Center Height |

1000MM |

Max.Temp for Cooling Water |

≤25℃ |

Lubricant |

HD-220# (The gear box is filled with lubricant before production) |

Min.Air Supply Pressure |

6bar |

Temperature during running |

|

Electric Control Box |

+10 bis +40℃ |

Motor |

+10 bis +40℃ |

Relative Air humidity: |

As per DIN 40040 F Level |

Noise Level |

65dB(A)+/-2Dba |

Production Line Direction |

from left to right |

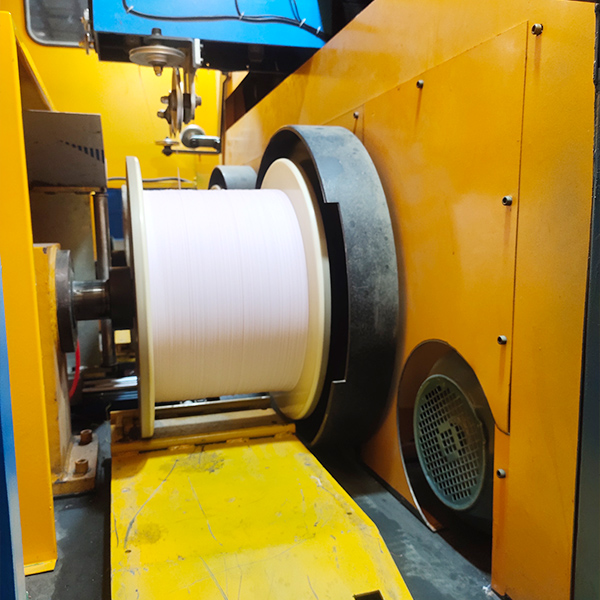

Pay Off and Take Up Bobbin Size

Pay Off Bobbin (Unit:MM)

Basket Take Up Bobbin(Unit:MM) |

|

|

|

Diameter Overall Width |

Inside Width |

Barrel |

Bore |

500 370 |

315 |

250 |

55 |

Electric Components

Items |

Details |

Production Norm Safety Level |

Refer to EN60204, EN954-1 |

Working Voltage Frequency |

3*400V, 50HZ |

Voltage Fluctuation |

±5% |

Zero Line |

Use zero line that can bear full load and have base 24V GS |

Control Voltage |

24V |

Magnetic Valve Voltage |

24 |

Light Voltage |

230V, 50HZ |

Electric Control Box Basement |

150MM |

Main Power Cable Inlet, |

TOP |

Control Cable Inlet |

Bottom

|

Motor |

Major is SIEMENS system, about 180KW total power for installation |

Equipment List

Configuration

No. |

QTY. |

Unit |

Name of product |

Type/Note |

Manufacturer |

1 |

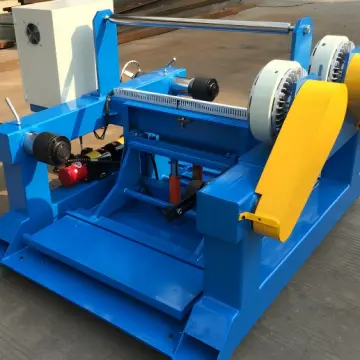

1 |

Set |

Coil- Type Vertical Pay Off |

630/800 |

GOLDEN |

2 |

1 |

Set |

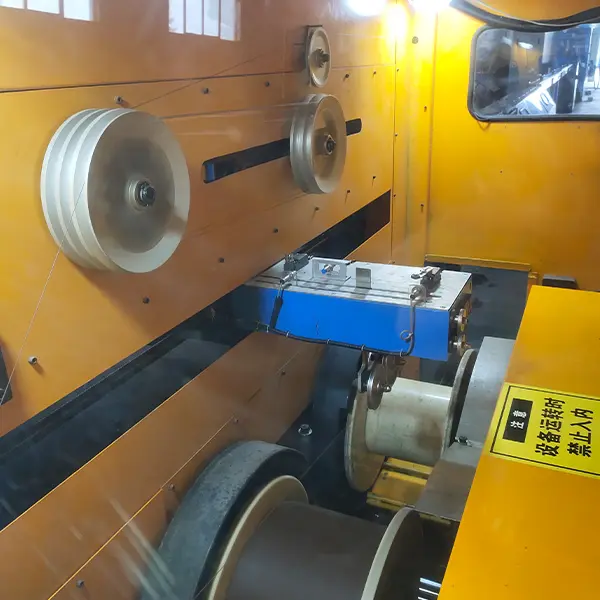

Drawing Machine |

ZL250-17D |

GOLDEN |

3 |

1 |

Set |

TH600SAnnealer |

TH600S |

GOLDEN |

4 |

1 |

Set |

Drawing Lubricant Circulation, Cooling and Copper Powder Filtration Device |

|

GOLDEN |

5 |

1 |

Set |

Steam Generator |

|

GOLDEN |

6 |

1 |

Set |

Annealing Cooling Fluid Circulation Cooling System |

|

GOLDEN |

7 |

1 |

Set |

Copper Wire Head Rolling and passing Machine (Equipped on the drawing machine) |

|

GOLDEN |

8 |

1 |

Set |

Pneumatic Tension Connecting Lever |

Pneumatic Type |

GOLDEN |

9 |

1 |

Set |

¢65Main Extruder |

|

GOLDEN |

9.1 |

1 |

Set |

Dosing Station for 65MM Extruder |

|

WOYWOD |