6000 tons Φ 12.5 mm - Φ 30 mm copper rod casting line

Equipment details

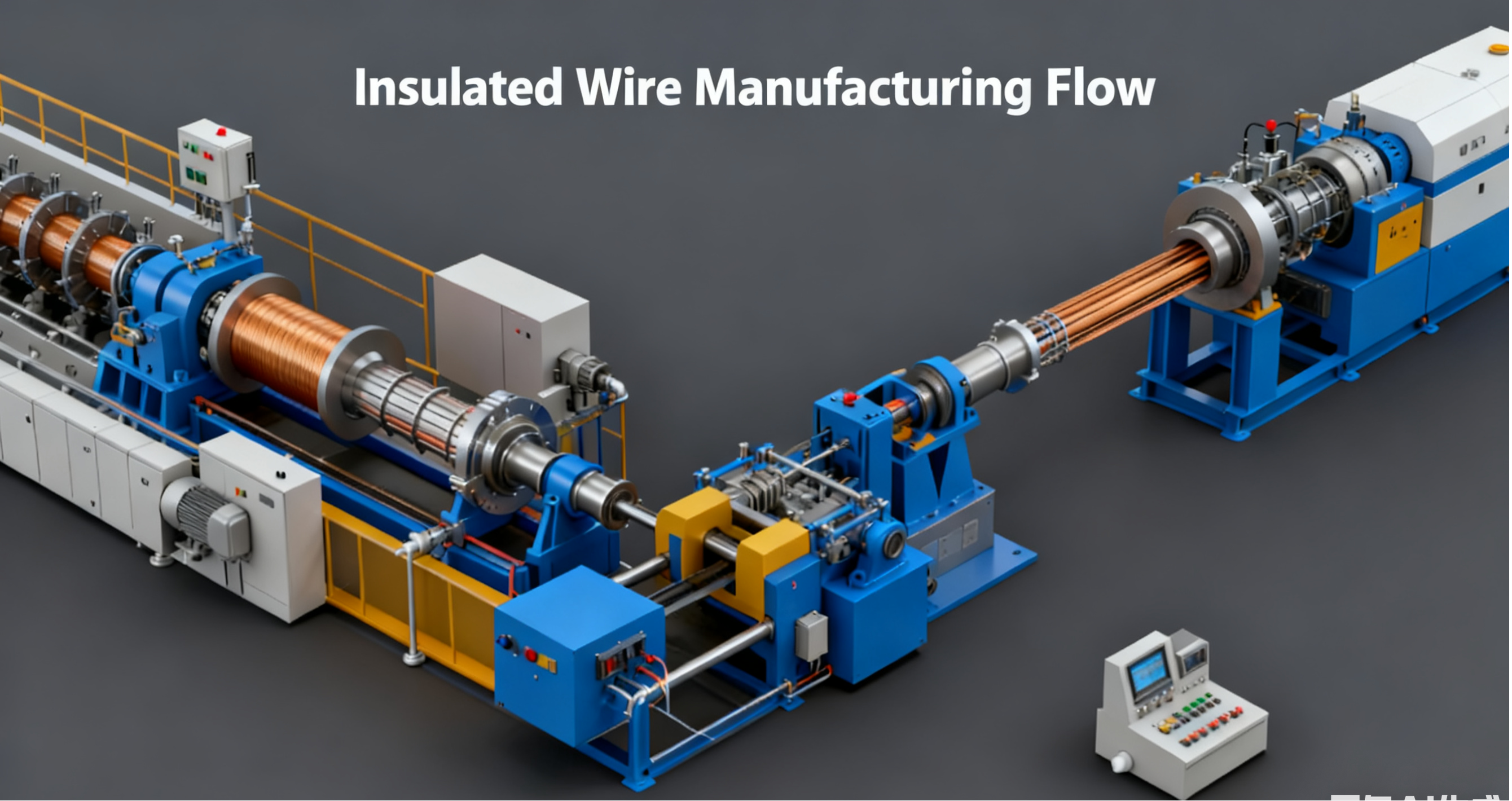

Equipment Overview

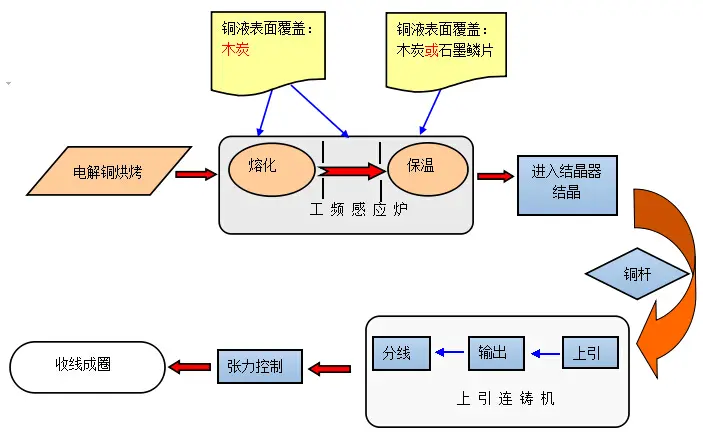

The upward copper rod continuous casting machine is used to produce long length bright oxygen-free copper rods. The unit melts the electrolytic copper into liquid through the industrial frequency induction furnace, isolates it from the air through the charcoal covering the surface (to prevent the copper liquid from oxidation), controls the temperature of the copper liquid at 1150℃± 5 ℃ through the insulation furnace, and the continuous casting machine rapidly crystallizes the copper liquid in the crystallizer to continuously produce copper rods, and finally loads it into a product through auxiliary equipment such as a double-head wire take-up machine.

Main parameters

1 |

Equipment model: SYJ 1012/30 -I3 |

2 |

Annual production capacity: 6 000 tons |

3 |

Installed capacity: 250KW AC three-phase 380 V 50Hz |

4 |

Furnace structure: large three- body combined furnace ( melting furnace on one side , compartment in the middle, holding furnace on the other side). The melting furnace has two 300 - type melting trenches ; the holding furnace has one 300 -type melting trench . |

5 |

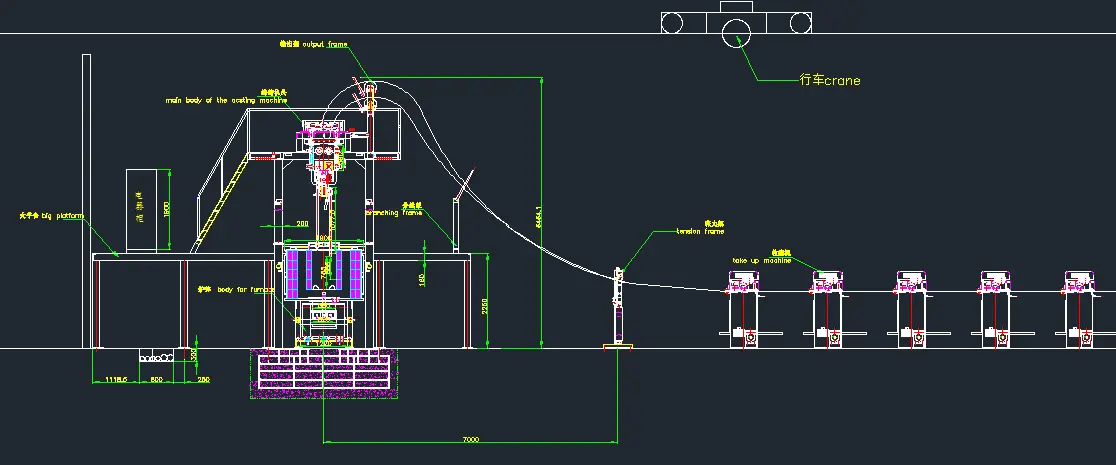

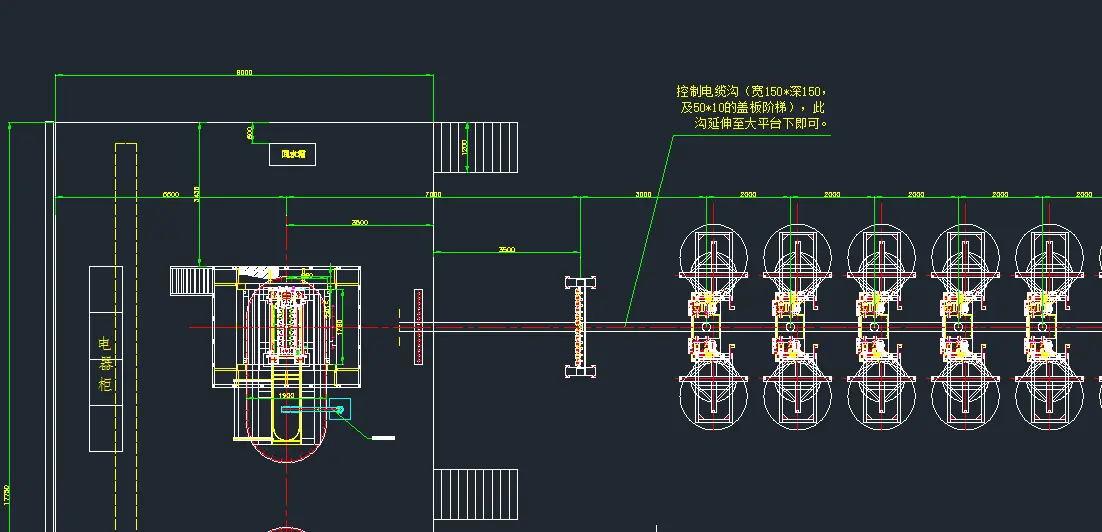

Wire take-up layout: Wire take-up machines are arranged in a single layer ( as shown in the diagram on the next page ) |

6 |

Number of casting rod heads: 2*5=10 in total . |

7 |

Casting rod diameter: Ф 12.5 mm~Ф 30 mm |

8 |

Pull-up speed: 0~ 1300mm /min |

9 |

Annual working hours: 7920 hours |

10 |

Level tracking accuracy: ± 2 mm |

11 |

Specifications of winding coil: φ800mm×φ 2200mm ×800mm |

12 |

Copper melting rate: 760 kg/h |

13 |

Copper melting power consumption rate: ≤ 320 kwh/ton ( power consumption rate for melting + heat preservation within half a year from the start of furnace power-on ) |

14 |

Charcoal consumption: 5 kg/ton of copper |

15 |

Reeling mode: automatic reeling |

16 |

Drive mode of take-up turntable: frequency conversion automatic rod arrangement |

17 |

Feeding method: Automatic copper plate feeder (optional) combined with manual arm electric hoist to feed the whole piece of copper |

18 |

Upper drive mode: AC servo motor drive, transmission chain adopts gapless synchronous toothed belt drive, a total of 2 groups |

19 |

Upper copper rod clamping method: manual clamping |

20 |

Operation interface: Data display and servo motor are controlled by touch screen. All temperature data collection is done by dedicated modules and displayed and monitored on the industrial control screen . It can also be connected to the customer's MES system . |

twenty one |

Furnace life: Under normal operation, the furnace life is not less than 1 to 2 months |

twenty two |

1 Melting furnace, holding furnace contactor electric voltage regulation (sensor protection method: special PLC programming protection) 2 Equipped with temperature measuring cabinet, control cabinet and operating table in the traction servo system adopts Japanese Yaskawa, the driver adopts Japanese Yaskawa, the PLC adopts Mitsubishi or Siemens, and the touch screen adopts a well-known domestic brand. 4. Among the electrical components, the inverters are all made by China Sine ; the voltage regulating contactors are made by China Chint high-end, and the other intermediate relays, thermal relays, etc. are made by Schneider or Chint high-end . The contactors used for the winding and wiring inverters are made by Schneider or Chint high-end , and the buttons and indicator lights are made by first-line brands. 5. Core: Spherical 6 Temperature measurement and display: The temperature of the copper liquid is measured in multiple areas and displayed by the large-screen temperature display. The water temperature is reflected by the water temperature meter. The measurement results are displayed on the digital thermometer and the industrial control screen to achieve production monitoring of the equipment. 7. Thermocouple for measuring copper liquid in holding furnace : Platinum-rhodium-platinum S, graduation number 1150mm 8 Transformer: Insulation Class F |

Equipment composition

The unit consists of a power frequency induction furnace, a melting furnace and a holding furnace, an upper continuous casting machine, a guide wheel frame, a tension frame, a double-head wire take-up machine, a water cooling system, an electrical system, a feeding system and a temperature measurement system. Most of the surfaces of the main equipment are sprayed with plastic, which not only responds to the national environmental protection call, but also improves product quality and beautifies the appearance of the equipment.

Equipment Description

Industrial frequency induction furnace

Industrial frequency induction furnace

Output rack guide wheel

Double-head take-up machine

description2

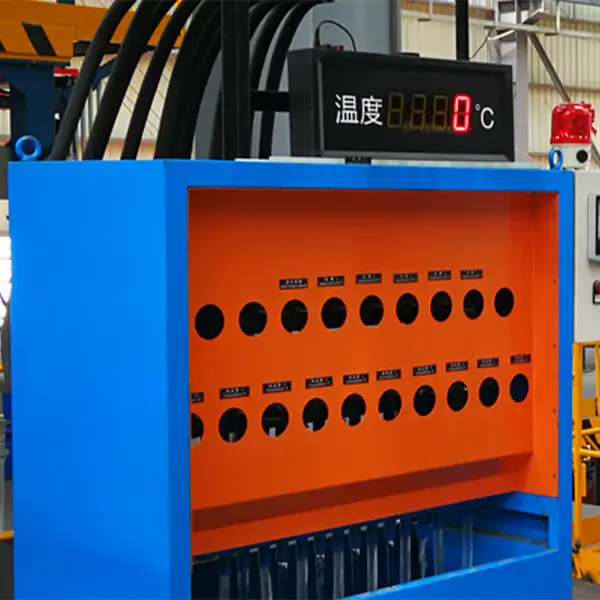

Water Cooling System

Electrical System

The electrical system consists of a power supply system and a control system. The power supply system supplies power to each sensor through several power cabinets. The control system ensures the normal production of the unit and the recording and display of data. The displayed and recorded contents include: sensor voltage, current, furnace temperature, water temperature of each line (including crystallizer water temperature), traction speed and traction pitch, etc.

The electrical system consists of a control cabinet and an operation cabinet. The control cabinet includes: the melting furnace uses two sets of 100K VA stepped autotransformer voltage regulating cabinets, the holding furnace uses a set of 100 K VA stepped autotransformer voltage regulating cabinets, and a set of temperature measuring cabinets (equipped with a communicative temperature data acquisition module).

The operating cabinet includes: a set of furnace, casting machine and servo integrated operating table.

Furnace operation part: current, voltage, power factor, power display, gear control and automatic temperature control system of holding furnace, equipped with PLC ( 1, control data acquisition system ), human-machine interface ( 1 7- inch , display the above data and implement related control )

Casting machine operation part: equipped with PLC ( 1, controlling the servo motor system ), human-machine interface ( 1 7- inch , controlling the servo motor system ), servo system, and responsible for the liquid level tracking control of the continuous casting machine. The human-machine interface can set the corresponding parameters through the PLC controller.

The electrical system can directly display the parameters in the production process digitally, and can also record, save and export them for analysis, and alarm when important parameters such as water pressure, holding furnace temperature, coil current, etc. are out of range.

Parameter ①: Power frequency furnace parameters (smelting furnace voltage, current, temperature; holding furnace voltage, current, temperature)

Parameter ②: Casting parameters (pulling pitch, pulling time, pause time, pulling acceleration, pulling reverse thrust, etc.)

This equipment can be configured with a PROFI-NET interface for communication with the buyer's MES system. The IP address of the interface is determined by the buyer.

The Seller will, based on the Buyer's requirements, place the required furnace and casting machine parameters, setup parameters, operating parameters and other addresses into a specific background data block for collection by the Buyer's data collection system.

Data collection signal points

Serial number |

name |

quantity |

Instrument Display |

Enter PLC |

Remark |

1 |

Total cabinet power |

1 set |

√ |

√ |

of power supply cabinet, melting furnace and holding furnace |

2 |

Incoming current collection |

√ |

√ |

||

3 |

Incoming voltage acquisition |

√ |

√ |

||

4 |

Power harvesting |

√ |

√ |

||

5 |

Power factor acquisition |

√ |

√ |

||

6 |

Single channel coil voltage |

√ |

√ |

||

7 |

Single channel coil current |

√ |

√ |

||

8 |

Copper liquid temperature |

√ |

√ |

||

9 |

Active Power |

√ |

√ |

||

10 |

Reactive power |

√ |

√ |

||

11 |

Inlet water temperature |

1 set |

√ |

√ |

Crystallizer water screen |

1 2 |

Return water temperature |

√ |

√ |

||

1 3 |

Inlet water pressure |

√ |

√ |

||

1 4 |

Each branch return water on-off information (switch quantity) |

√ |

√ |

||

1 5 |

Return water temperature |

1 set |

√ |

√ |

Inductive water dispenser |

1 6 |

Each branch return water on-off information (switch quantity) |

√ |

√ |

||

17 |

Total water supply flow |

|

√ |

√ |

(Customer selection) |

18 |

Total return flow |

|

√ |

√ |

(Customer selection) |

19 |

Number of upper leads |

1 set |

√ |

√ |

Tractor |

20 |

Specifications |

1 set |

√ |

√ |

|

twenty one |

Traction speed |

1 set |

√ |

√ |

|

twenty two |

Pulling pitch |

√ |

√ |

||

twenty three |

Production site management records (manual input):

|

|

|

|

Production date/batch/shift/raw material input quantity/shift production output Time management for winding and reel changing; Time management for crystallizer replacement Graphite mold replacement time management; Graphite protective sleeve replacement time management |

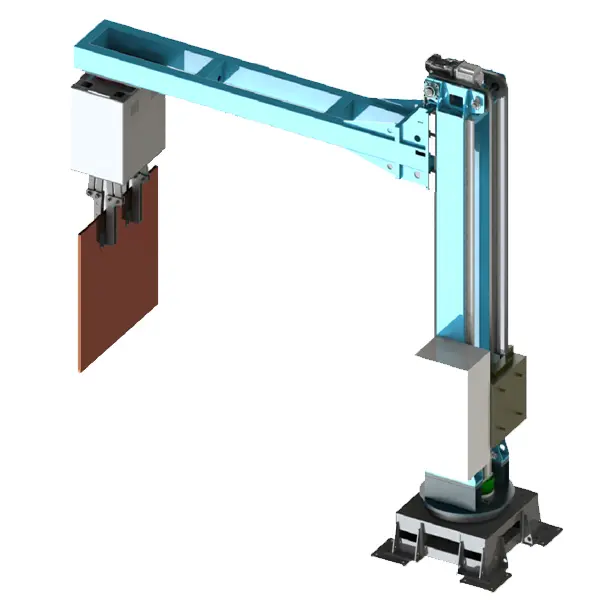

Feeding system

The feeding system is a mechanical whole piece electrolytic copper feeding system, which ensures that the electrolytic copper is continuously supplied to the melting furnace ; hydraulic packing can also be added. In order to ensure reliable feeding, this system is equipped with a hand-operated electric hoist feeding system, and customers can also choose an automatic feeding system.

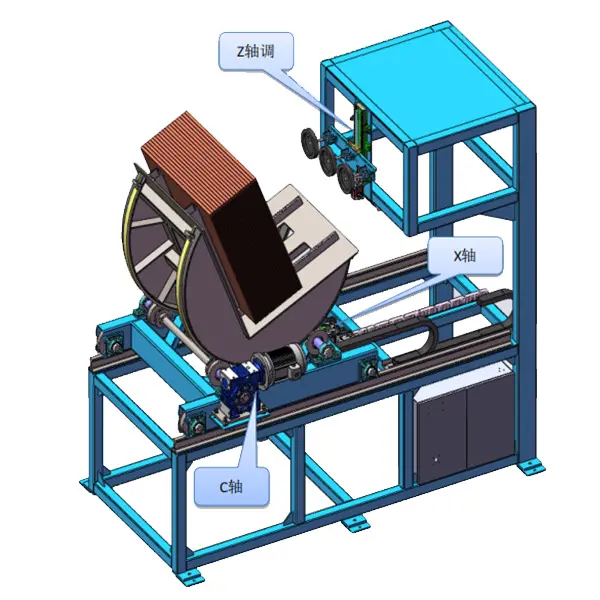

Parameters and configuration of automatic feeder for electrolytic copper plate

A Technical Specifications of Electrolytic Copper Plate Feeding Column Robot

Technical Specifications of Three-axis Column Robot for Electrolytic Copper Plate Feeding | ||||

Serial number |

Project Name |

Specifications/Parameters |

Remark |

Column robot |

1 |

Equipment quality |

About 1100kg |

|

|

2 |

Total height of equipment |

Maximum: about 3460mm |

|

|

3 |

Area |

0.85m² |

920*920mm |

|

4 |

Maximum load |

300kg |

|

|

5 |

C1 axis motor power |

1.5KW (Servo motor) |

Xinjie |

|

6 |

C1 axis travel |

0-360° |

|

|

7 |

C1 rated speed |

30°/s |

|

|

8 |

Z-axis motor power |

1.5KW (Servo motor) |

Xinjie |

|

9 |

Z-axis effective travel |

1700mm |

|

|

10 |

Z-axis rated speed |

200mm/s |

|

|

11 |

Y-axis motor power |

- |

|

|

12 |

Y-axis effective travel |

- |

|

|

13 |

Maximum speed of Y axis |

- |

|

|

14 |

C2 axis motor power |

750W (Servo motor) |

Xinjie |

|

15 |

C2 axis travel |

0-360° |

|

|

16 |

C2 axis rated speed |

64°/s |

|

|

17 |

Radius of rotation |

R2600mm |

|

|

18 |

Claw |

Electric controlled clamping claw |

|

|

19 |

sensor |

Meiji Sensor |

|

|

20 |

Electronic Control |

Chint low configuration |

|

|

twenty one |

PCL |

Inovance PLC |

|

|

twenty two |

lubricating |

Automatic lubrication |

|

|

twenty three |

Drag chains |

Double Xu: Fully enclosed |

|

|

B Electrolytic Copper Plate Feeding and Turning Material Warehouse Technical Specifications

Serial number |

Project Name |

Specifications/Parameters |

Remark |

Column robot |

1 |

Equipment quality |

Approx. 1100 kg |

|

|

2 |

Equipment size specifications |

3000*1560*2628 mm (length*width*height) |

|

|

3 |

Area |

4.68m² |

|

|

4 |

Maximum load |

3000 kg |

|

|

5 |

C-axis motor power |

3 KW (three-phase asynchronous motor) |

With brake |

|

6 |

C-axis travel |

0-120° |

|

|

7 |

C-axis rated speed |

16.8°/s |

|

|

8 |

Z-axis motor power |

750 KW (Servo motor) |

Xinjie |

|

9 |

Z-axis effective travel |

280 mm |

|

|

10 |

Z-axis rated speed |

200 mm /s |

|

|

11 |

X-axis motor power |

1.0 KW (Servo motor) |

|

|

12 |

X-axis effective travel |

1100 mm |

|

|

13 |

X-axis maximum speed |

314 mm /s |

Only low speed driving is allowed |

|

14 |

C2 axis motor power |

|

|

|

15 |

C2 axis travel |

|

|

|

16 |

C2 axis rated speed |

|

|

|

17 |

Claw |

Vacuum suction cup gripper |

|

|

18 |

sensor |

Meiji Sensor |

|

|

19 |

Electronic Control |

Chint low configuration |

|

|

20 |

PL C |

Inovance PLC |

|

|

twenty one |

lubricating |

Automatic lubrication |

|

|

Process

The electrolytic copper plate is lifted to the melting furnace for baking by using the copper lifting mechanism → The feeding speed is determined according to the upward pulling speed, and the electrolytic copper plate is added to the melting furnace to melt into copper liquid (charcoal is needed to cover it at this time to remove oxygen and isolate oxygen) → The copper liquid enters the transition cabin (charcoal is still needed at this time to further remove oxygen and isolate oxygen) → The copper liquid enters the insulation furnace → The copper liquid enters the crystallizer and crystallizes into copper rods → The copper rods enter the traction mechanism to be pulled up → The copper rods enter the output rack → The copper rods enter the wire distribution rack (so that the copper rods will not be entangled with each other) → The copper rods enter the tension rack (to control the wire taking-up speed) → The copper rods enter the wire take-up machine to take up the wire into a coil → Enter the next process

Layout drawing (for reference only)

Other Notes

Power requirements:

Power requirements:

Equipment Configuration List

SYJ 1012/30 -I3 Equipment Configuration List

1. Continuous Casting Machine | ||||

Serial number |

name |

quantity |

illustrate |

Remark |

1 |

Middle Platform |

1 set |

The head mounting parts on the large platform are all made of seamless square tubes, with beautiful appearance |

|

2 |

Traction head |

1 set |

Jiyun's unique design of traction connection uses international standard expansion sleeves, without transmission gap |

|

3 |

Crystallizer clamping mechanism |

1 set |

The crystallizer clamping mechanism is rigorous, and the installation of the crystallizer is simple, easy to operate and safe. |

|

4 |

Return tank |

1 set |

The electric box panel design is beautiful and practical Return water temperature and flow rate can be observed |

|

5 |

Output rack |

1 set |

|

|

6 |

Servo and machine head Electrical operating table |

1 set |

Contains 1 set of Japanese Yaskawa AC servo system, Mitsubishi PLC, touch screen made in Taiwan |

|

7 |

Loading and lifting equipment |

1 set |

Traveling electric hoist ( 1 ton ) |

|

8 |

Tension frame |

1 |

|

|

9 |

Crystallizer |

10 |

12.5-30, specifications to be determined by then |

|

10 |

Cooling water rubber hose |

20 pieces |

With matching quick connector |

|

11 |

Float |

1 item |

|

|

12 |

Crystallizer protective cover |

10 |

|

|

13 |

Crystallizer insulation sleeve |

10 |

|

|

14 |

Graphite mold |

10 |

|

|

15 |

Thermocouple |

1 piece |

|

|

16 |

Guide rod |

1 root |

|

|

2. I3 three-body furnace | ||||

1 |

Furnace body |

1 set |

|

|

2 |

Insulation board |

1 set |

|

|

3 |

Melt groove |

1 set |

|

|

4 |

Aluminum silicate board |

2 boxes |

|

|

5 |

Round bakelite pad |

18 items |

|

|

6 |

Quartz sand |

5500Kg |

Mixed sand |

|

7 |

Straight Lightweight Brick |

1 set |

|

|

8 |

Wedge-shaped lightweight brick |

1 set |

|

|

9 |

Molded bricks |

1 set |

|

|

10 |

Refractory Clay |

1 bag |

|

|

11 |

Water Glass |

1 barrel |

|

|

12 |

Asbestos rope |

2 Kg |

|

|

13 |

Electrical cabinet for furnace |

1 set |

|

|

14 |

Iron Core |

1 set |

2 melting furnaces, 300 type, 1 holding furnace, 300 type |

|

15 |

Coil |

1 set |

2 melting furnaces, 300 type, 1 holding furnace, 300 type |

|

16 |

Water Jacket |

1 set |

2 melting furnaces, 300 type, 1 holding furnace, 300 type |

|

17 |

Positioning plate for furnace |

1 set |

|

|

3. Wire Take-up Machine | ||||

Serial number |

name |

quantity |

illustrate |

Remark |

1 |

Wire take-up machine body |

5 sets |

|

|

2 |

Positioning device |

10 sets |

5 symmetrical on each side |

|

3 |

Wire take-up trolley |

10 sets |

5 symmetrical on each side |

|

4 |

Take-up reel |

10 sets |

5 symmetrical on each side |

The uniquely designed upward copper rod precision coiling machine is adopted (a frequency converter drives a motor reducer directly connected to the coiling disc, non-friction transmission, no transmission loss, making the coils more neatly arranged) , and the diameter of the copper rod to be coiled can be taken into account regardless of size |

4. Electrical appliances and other configurations | ||||

Serial number |

name |

quantity |

illustrate |

Remark |

1 |

Low voltage electrical appliances |

1 set |

Adopt Schneider (Shanghai) or Chint high-end |

|

2 |

Stove appliances |

1 set |

Using Chint high-end |

|

3 |

Take-up reducer |

1 set |

Zhejiang Sankai |

|

4 |

AC servo system |

1 set |

2 sets of Yaskawa AC servo systems , touch screen made in Taiwan , Mitsubishi PLC, Schneider low voltage electrical appliances or Chint high-end |

|

5 |

Traction reducer |

1 set |

Adopt high-precision and high-torque planetary reducer (Zhejiang Sankai) |

|

6 |

Frequency Converter |

1 set |

China Sine or Delta |

|

V. Others | ||||

1 |

Automatic feeding machine for electrolytic copper plate |

1 set |

|

Customer selection |

2 |

Large platform for the traction machine and the platform for the take-up machine |

1 set |

Including materials (including welding accessories) and on-site production |

Customer selection |

3 |

Wires, cables and bridges for the entire equipment |

1 set |

the main electrical cabinet of the upper hoisting machine equipment (arranged according to the equipment layout diagram provided by the supplier), including materials and on-site production |

Customer selection |

4 |

Cooling water pipeline of the whole equipment |

1 set |

All cooling water pipes related to the upper pull-up machine equipment (arranged according to the equipment layout provided by the supplier), including materials and on-site fabrication. Galvanized pipes for water supply and PVC pipes for return water |

Customer selection |

5 |

Bag type dust removal equipment |

1 set |

Including air ducts, which can be used for 2 sets of 6,000-ton equipment , including materials and on-site production. |

Customer selection |

6 |

15KW multistage centrifugal water pump |

2 units |

One for backup and one for use. Including materials and on-site production. |

Customer selection |

7 |

Air compressor ( 1.0 m3 , 0.9Mpa ) |

2 units |

Each unit can be used for 2 sets of 6000 ton equipment, one for backup and one for use. Including gas storage tank , including materials and on-site production. |

Customer selection |

8 |

Square cooling tower ( 50m3 / hour ) |

1 unit |

Including raw materials and on-site production. |

Customer selection |

9 |

Transportation and insurance of equipment |

1 serving |

|

Customer selection |

|

|

|

|

|

Customers should prepare

Serial number |

name |

quantity |

illustrate |

Remark |

1 |

Equipment Basics |

1 set |

For fixing the furnace body and the middle platform (the supplier shall provide drawings) |

|

2 |

Wire and Cable |

1 set |

Used for connection between workshop power cabinet and equipment main cabinet |

|

3 |

Wire Tray |

1 set |

Used for connection between workshop power cabinet and equipment main cabinet |

|

4 |

Water supply system |

1 set |

Including a 120m³ pool, emergency water tower, emergency water source |

|

5 |

Generator Set |

1 |

Capacity: 200KW , as backup power supply |

|

6 |

Power supply system |

1 set |

1. Power requirements: Voltage: Main circuit 380V three-phase Control circuit 220V single phase Frequency 50HZ 2. Unit installed capacity table: Furnace system: The installed capacity of the melting furnace inductor is 2*100KVA; the output power is 2*75kW=150kW The installation capacity of the holding furnace inductor is 1*100KVA; the output power is 1*75kW=75kW Continuous casting machine system: servo motor 4.4kW*2=8.8kW Lifting motor: 3kW Wire take-up system: Traction motor: 0.55kW*10 =5.5kW Looping motor: 0.25kW×10 =2.5kW Water pump: 15kW×2 units=30kW 3. Installed capacity: ≈350KVA 4. Actual operating power: 200~250kW

|

|

7 |

Electric Driving |

1 set |

5 tons |

|

8 |

Raw materials |

10 0 tons |

For trial production |

|

9 |

charcoal |

5 tons |

For trial production |

|

10 |

Graphite flakes |

1 ton |

For trial production |

|

11 |

Factory |

|

Arrange according to actual situation |

|

12 |

All equipment and tools related to installation and trial production |

1 set |

Such as: electric welding machine, gas cutting, pneumatic pick, forklift and other lifting equipment and other tools |

|

13 |

Furnace builder |

3-4 people |

The supplier's engineer guides the operation |

Equipment Consumables List SYJ 1012/30 -I3 Annual Production Consumables List (single set, customers need to purchase separately)

Serial number |

name |

Specification |

unit |

consumption |

1 |

Graphite mold |

Ф 12.5 mm / Ф 20 mm |

Only |

5 tons/piece |

2 |

Graphite protective sleeve |

Ф 12.5 mm / Ф 20 mm |

Only |

5 tons/piece |

3 |

Insulation sleeve |

Ф 12.5 mm / Ф 20 mm |

Only |

5 tons/piece |

4 |

Crystallizer |

Ф 12.5 mm / Ф 20 mm |

Only |

250 tons/piece |

5 |

Crystallizer inner tube |

Ф 12.5 mm / Ф 20 mm |

root |

250 tons/piece |

6 |

Water Jacket |

Model 300 |

set |

1 set /year |

7 |

Coil |

Model 300 |

set |

1 set /year |

8 |

Melt groove |

Model 300 |

set |

1 set /year |

9 |

Quartz sand |

Mixed sand |

ton |

5.5 tons/year |

10 |

Molded bricks |

I3N type |

set |

1 set/year |

11 |

Straight lightweight brick |

|

set |

1 set/year |

12 |

Wedge-shaped lightweight brick |

|

set |

1 set/year |

13 |

Fiberboard |

δ=20mm |

box |

2 boxes/year |

14 |

Asbestos Sheet |

δ=5mm |

box |

1 box/year |

15 |

Quick Connectors |

DG15 |

Item |

6 items/year |

16 |

Glass Ribbon |

|

roll |

60 volumes/year |

17 |

Hose joint |

1600mm |

root |

5 pieces/year |

18 |

charcoal |

|

ton |

5 kg/ton |

19 |

Flake Graphite |

3299 |

ton |

0.5 kg/ton |

Price

Single set 12.5 mm -30 mm 10 heads 6000 tons lifting machine production line quotation | |||||

Serial number |

name |

quantity |

unit price |

total |

Remark |

1 |

12.5 mm -30 mm 10 heads 60 00 tons lifting machine |

1 set |

|

600,000 |

Jiyun Machinery Standard Configuration (including process parameter information acquisition system and detection alarm system ) |

2 |

Multi-axis servo electrolytic copper plate automatic feeder |

1 set |

|

180,000 |

|

3 |

Total inlet and return water flow meter and alarm system |

1 set |

|

20,000 |

|

4 |

Large platform for lifting machine |

1 set |

|

80,000 |

Including materials (including welding accessories) and on-site production |

5 |

Wires, cables and bridges for the entire equipment |

1 set |

|

45,000 |

the main electrical cabinet of the upper hoisting machine equipment (arranged according to the equipment layout diagram provided by the supplier), including materials and on-site production |

6 |

Cooling water pipeline of the whole equipment |

1 set |

|

40,000 |

All cooling water pipes related to the upper pull machine equipment (arranged according to the equipment layout provided by the supplier), including materials and on-site production. Galvanized pipes for water supply and galvanized pipes for return water |

7 |

Bag type dust removal equipment (Zhejiang Tianwei) |

1 set |

|

220,000 |

Including air ducts, which can be used for 2 sets of 6,000-ton equipment , including materials and on-site production. |

8 |

15 KW multistage centrifugal water pump (Nanfang Pump Industry) |

2 units |

|

30,000 |

One for backup and one for use. Including materials and on-site production. |

9 |

Screw air compressor ( 1.0 m3 , 0.9Mpa) (Kaishan , Zhejiang) |

2 units |

|

40,000 |

It can be used for 2 sets of 6000 tons equipment, one for backup and one for use. Including gas storage tanks , including materials and on-site production. |

10 |

Square cooling tower ( 50m3 / h ) with circulating water pump |

1 unit |

|

22,000 |

Including raw materials and on-site production. |

11 |

4T/h reverse osmosis water purifier (Shanghai Bosen) |

1 unit |

|

100,000 |

|

12 |

Transportation and insurance of equipment |

1 serving |

|

|

5 17.5m flatbed trucks (including all the above equipment) Note: This freight quotation is subject to the market price at that time. |

|

Standard equipment only requires two 17.5-meter flatbed trucks Note: This freight quotation is subject to the market price at that time. |

||||

13 |

The supplier 's accommodation, transportation and other expenses for the installation and commissioning personnel, as well as the equipment acceptance and training expenses |

1 serving |

|

0 million |

Overseas installation and commissioning costs are negotiable |

|

|

|

|

|

|

|

|

|

|

|

|

Note: Items 2 to 13 are optional for customers | |||||

Payment Terms

Delivery

Installation, commissioning and acceptance

2. After the test run is completed, the supplier representative shall notify the buyer for acceptance. The buyer shall conduct acceptance within three days after the test run is completed, and submit written objections to whether it complies with the regulations and handling opinions. If the buyer does not raise any objection within the above period, the equipment supplied shall be deemed to comply with the contract provisions.

Warranty

The supplier has sold the goods in recent years

Partial export sales

Serial number |

unit |

Sales Project |

quantity |

1 |

KENO TRADING LIMITED (Russia) |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

2 |

KENO TRADING LIMITED (Russia) |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

3 |

STELLAR POWERHOURSE PTE LTD(Myanmar) |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

4 |

Xinjiang Wotan Import and Export Trading Co., Ltd. |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

5 |

Malaysia Nissin |

15,000 ton Φ 8 mm upward copper rod continuous casting machine |

4 units |

6 |

Pingxiang Maofa Import and Export Trading Co., Ltd. |

3000 ton Φ17mm upper copper rod continuous casting machine |

1 unit |

7 |

SPM POWER & TELECOM PVT LTD (India) |

3000 ton Φ17mm upper copper rod continuous casting machine |

2 units |

8 |

Shanghai Boao Import and Export Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

9 |

Zhejiang Huixin Import and Export Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

10 |

Zhejiang Huixin Import and Export Co., Ltd. |

2000 ton Φ17mm copper rod continuous casting machine |

1 unit |

11 |

Hunan Aotel Foreign Economic and Technological Development Co., Ltd. |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

12 |

Hunan Aotel Foreign Economic and Technological Development Co., Ltd. |

10000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

13 |

FORUSR (Brazil) |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

14 |

VINH THINH ELECTRIC CABLE CO.,LTD (Vietnam) |

2000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

15 |

SHANGHAI BROTHERS (INDORE) PVT LTD (India) |

2000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

16 |

KHATEEB CO., LTD (Syria) |

2000 ton Φ17mm upward copper rod continuous casting machine |

1 unit |

17 |

SIDAS GLOBAL PTELTD (Uzbekistan) |

3000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

18 |

PERSIAN ETESAL SPADANA (Iran) |

5000 ton Φ8mm upward copper rod continuous casting machine |

2 units |

19 |

SIAM CABLE WAY CO., LTD (Thailand) |

3000 ton Φ17mm upper copper rod continuous casting machine |

1 unit |

Partial export sales

Serial number |

unit |

Sales Project |

quantity |

1 |

Taiwan Changchun Petrochemical Co., Ltd. |

10000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

2 |

Ningbo Bowei Alloy Material Co., Ltd. |

12000 tons Φ8~Φ16mm upward copper rod continuous casting machine |

7 units |

3 |

Huigao Precision Electronics Industrial Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

4 |

Yunnan Huitong Copper Industry Co., Ltd. |

12000 tons Φ8~Φ16mm upward copper rod continuous casting machine |

2 units |

5 |

Jiangxi Kaian Copper Co., Ltd. |

12000 tons Φ8~Φ16mm upward copper rod continuous casting machine |

1 unit |

6 |

Hongqi Group Jiangxi Copper Co., Ltd. |

5000 ton Φ17mm upper copper rod continuous casting machine |

1 unit |

7 |

Hongqi Group Jiangxi Copper Co., Ltd. |

6000 ton Φ8mm upward copper rod continuous casting machine |

2 units |

8 |

Hongqi Group Jiangxi Copper Co., Ltd. |

8000 ton Φ8~Φ17mm upper copper rod continuous casting machine |

3 units |

9 |

Jiangsu Gangda Metal Materials Co., Ltd. |

8000 ton Φ12.5mm upward copper rod continuous casting machine |

2 units |

10 |

Huzhou Shenxin Copper Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

11 |

Taizhou Siling Electric Co., Ltd. |

5000 ton Φ17mm upper copper rod continuous casting machine |

1 unit |

12 |

Zhejiang Mingheng Cable Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

13 |

Qingyuan Changfa Enameled Wire Copper Material Co., Ltd. |

6000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

14 |

Qingyuan Changfa Enameled Wire Copper Materials Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

2 units |

15 |

Jiaxing Zhongxing Plastic Industry Co., Ltd. |

5000 ton Φ17mm upward copper rod continuous casting machine |

2 units |

16 |

Suzhou Jinhui Copper Materials Co., Ltd. |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

17 |

Longkou Wire and Cable Factory |

5000 ton Φ17mm upward copper rod continuous casting machine |

2 units |

18 |

Longkou Wire and Cable Factory |

5000 ton Φ8mm upward copper rod continuous casting machine |

1 unit |

19 |

Suzhou Zhongxing Copper Co., Ltd. |

5000 ton Φ20mm upward copper rod continuous casting machine |

1 unit |

20 |

Jiangsu Zhongxing Copper Co., Ltd. |

6000 ton Φ17mm copper rod continuous casting machine |

1 unit |

twenty one |

Taizhou Deke Metal Materials Co., Ltd. |

5000 ton Φ17mm upward copper rod continuous casting machine |

2 units |

twenty two |

Qingdao Xindeyi Copper and Aluminum Products Co., Ltd. |

5000 ton Φ20mm upward copper rod continuous casting machine |

1 unit |

twenty three |

Wen'an County Mei'aote Electric Appliance Co., Ltd. |

6000 ton Φ17mm copper rod continuous casting machine |

1 unit |

twenty four |

Xin'an Cable Material Co., Ltd. |

6000 ton Φ17mm copper rod continuous casting machine |

1 unit |

25 |

Anhui Tianda Copper |

12 000 ton Φ 12.5-20 mm upper copper rod continuous casting machine |

2 units |

26 |

Anhui Chujiang Alloy |

12 000 ton Φ 12-16 mm brass rod continuous casting machine |

5 units |

27 |

Hubei Jintong Copper Industry |

6000 ton Φ17mm copper rod continuous casting machine |

1 unit |