Customization of Non-standard Components and Devices

Module Categories

Featured Module

Specification for Φ800 Steel Tape Armoring Machine Production Line

2025-10-30

I. Equipment Purpose

Suitable for continuous steel tape lapping and armoring of power cables with metal sheaths;

II. Main Specifications

- Adaptable cable diameter: Φ10mm - Φ100mm

- Maximum production line speed: 80m/min (depending on steel tape width and overlap width)

- Pay-off reel specification: PN1600~PN3150

- Take-up reel specification: PN1600~PN3150

- Traction force: 2000KG

- Dual-disk lapping motor: 15kW (AC servo motor)

- Steel tape armoring motor: 22kW (AC servo motor)

- Traction motor: 15kW (AC servo motor)

- Center height: 1000mm

- Power supply: 380V±10%, 50HZ, three-phase five-wire system

- Operation direction: Facing the operation - Left-hand machine (right pay-off → left take-up) □; Right-hand machine (left pay-off → right take-up) □

- Machine color: Overall exterior - Blue orange texture RAL5015 (color card provided by customer)

- Electric cabinet exterior: RAL7035 gray-white corrugated paint

- Safety color: Yellow

III. Composition of Single Set of Equipment

| No. | Equipment Name | Specification | Quantity | Function | Remarks |

|---|---|---|---|---|---|

| 1 | Gantry-type Magnetic Powder Driven Pay-off Machine | Φ1600-3150 | 1 unit | Wire pay-off | - |

| 2 | Aligner | DZQ | 1 unit | Wire centering | - |

| 3 | Semi-cut Non-metallic Tape Lapping Main Machine | 630*2 | 1 unit | Wire lapping | - |

| 4 | Semi-cut Steel Tape Armoring Main Machine | 800*2 | 1 unit | Wire lapping | - |

| 5 | Unit Synchronous Control System | KZR-2.0 | 1 unit | Lapping control | - |

| 6 | Mechanical Length Counter | JMA-159.16 | 1 unit | Cable length measurement | - |

| 7 | Crawler-type Traction Machine | 2000KG | 1 unit | Tension control | - |

| 8 | Aligner | DZQ | 1 unit | Wire centering | - |

| 9 | Gantry-type Take-up Machine | Φ1600-3150 | 1 set | Cable take-up | - |

| 10 | Molding Die | Provided by customer | 1 set | Cable restraint | - |

| 11 | Spare Tools | Professional tools | 1 set | Equipment accessories | - |

IV. Equipment Introduction of Production Line Components

Φ1600/3150 Gantry-type Passive Pay-off Rack

- Pay-off rack type: Gantry ground rail traveling, magnetic powder tension

- Adaptable reels: PN1600—PN3150

- Reel diameter range: Φ1600~Φ3150mm

- Adaptable reel width: 1300~2300mm

- Adaptable cable diameter: Φ10—Φ120mm

- Travel motor: 2.2kw AC motor + cycloidal pinwheel reducer (1 set)

- Lifting motor: 3kw AC motor + cycloidal pinwheel reducer (2 sets)

- Clamping motor: 0.75kw AC motor + cycloidal pinwheel reducer (1 set)

- Load capacity: 20 tons

- Structure type: Gantry ground rail traveling type, upper sleeve type; gantry frame formed by bending and welding; the two centers of the reel are lifted by lead screws and nuts driven by two motors via cycloidal reducers; each center seat can be lifted individually or simultaneously, with dual mechanical and electrical protection devices; different specifications of center sleeves can be equipped if needed to meet the installation of different reel specifications; reel clamping is achieved via motor-reduction, with clamping overload protection.

- Tension mode: Passive tension by magnetic powder brake, adjustable tension according to cable size.

Aligner

When the pay-off rack moves left or right, the command is controlled by signals from the aligner installed at the front end of the pay-off rack, ensuring the wire is always paid off at the center position.

Semi-cut Non-metallic Tape Lapping Main Machine

- Adaptable cable diameter: Φ10~Φ60mm

- Tape thickness: 0.1~0.4mm

- Tape reel specification: Φ630×Φ80×(15~80)mm

- Tray outer diameter: Φ650×14mm

- Number of tape reels: 2

- Lapping head speed: 600rpm

- Lapping head pitch: Steplessly adjustable

- Motor power: 15kw (permanent magnet servo motor)

- Equipment direction: Right-hand machine/Left-hand machine

- Equipment center height: 1000mm

- Tape pay-off tension: Controlled by imported German ZF hysteresis tension control, with automatic adjustment.

- Driven by a separate permanent magnet servo motor, speed regulated by frequency converter; lapping pitch adjusted proportionally to meet the pitch requirements of the lapping process.

- The main machine is equipped with a pneumatic clamp-type brake device (equipped with a compressed air storage tank); brake speed can be adjusted via air pressure to achieve consistent overall braking, inching and other actions.

- Equipped with tape breakage stop function (pulse vector detection) to realize automatic shutdown and compensation.

- Equipped with bearing temperature sensing; pre-alarm and shutdown when temperature is too high.

- Lubrication method: Automatic timed oil injection for spindle bearing seats.

- Safety cover: Axially movable (push-pull type), fully enclosed structure.

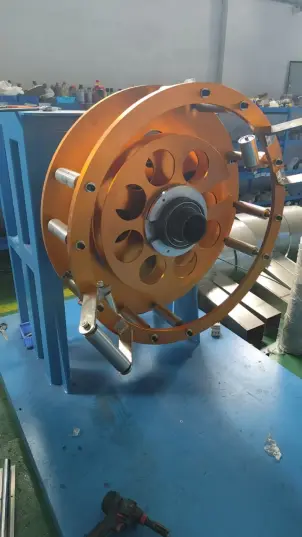

Φ800×2 Semi-cut Steel Tape Armoring Machine

- Adaptable cable diameter: Φ10~Φ100mm

- Tape thickness: 0.2~0.8mm

- Tape reel specification: Φ630×Φ200×(20~60)mm

- Number of tape reels: 2 (See Image)

- Steel tape head speed: 600rpm

- Steel tape head pitch: Steplessly adjustable

- Motor power: 22kw (AC servo motor)

- Equipment direction: Right-hand machine/Left-hand machine

- Equipment center height: 1000mm

- Tape pay-off tension: Controlled by imported German ZF hysteresis tension control, with automatic adjustment.

- The steel tape head adopts an integral frame structure: after integral welding to eliminate internal stress, integral machining is performed, and finally dynamic balance verification is conducted, suitable for high-speed operation with low failure rate.

- Driven by a separate AC variable frequency motor, speed regulated by frequency converter; lapping pitch adjusted proportionally to meet the pitch requirements of the lapping process.

- The steel tape armoring machine is equipped with a pneumatic clamp-type brake device; brake speed can be adjusted via air pressure to achieve consistent overall braking, inching and other actions.

- The discharged steel tape passes through multiple guide rollers, which play the role of tape stabilizing and leveling.

- Equipped with tape breakage stop function (pulse vector detection) to realize automatic shutdown and compensation.

- Safety cover: Axially movable (push-pull type), fully enclosed structure.

Unit Synchronous Control System + Console-type Operation Platform

- The entire machine is operated via a 10.7-inch touch screen, controlled by Siemens PLC; the operating system is reasonably and reliably designed, with Ethernet interface and support for MES system data interface.

- The touch screen displays the speed, current, frequency signals of each motor, as well as line speed, length counting and other information.

- The control panel is equipped with separate control buttons for operation; the speed of the main lapping head and traction is given via communication, with single-action and linkage control functions.

- During the linkage speed-up process of the entire machine, synchronous control is well implemented; the lapping pitch can be automatically tracked with closed-loop control to accurately control the steel tape overlap rate and save materials.

- Length counting mode: Internal length counting, displayed on the touch screen;

- Controller type: Servo and frequency conversion control

- Separate power cabinet + operation control platform

Mechanical Length Counter

- Components: Mechanical bracket, left-right double wheels, 5-digit length counter, encoder, etc.;

- Type: Double-wheel (horizontal structure); two pressure wheels are equipped with buffer springs, with automatic centering function; wire guide rollers are provided for both wire inlet and outlet;

- Length counter wheel diameter: 159.15mm;

- Length counting range: 9999m;

- Length counter wheel circumference: 500mm;

- Length counting accuracy: 0.3%;

- Material: Aluminum alloy wheel circumference;

- Counting method: Dual length counting via 5-digit length meter combined with encoder;

- Length counter wheel surface: Electroplated.

2000kg Crawler-type Traction Machine

- Cable passing outer diameter: φ130mm

- Maximum traction force: 2000kg

- Traction speed: 2.3-80m/min

- Crawler contact length: 2395mm

- Number of cylinder pairs: 7 pairs

- Equipment center height: 1000mm

- Main motor: 15kw permanent magnet servo motor

- Pneumatic emergency stop brake

Aligner

When the take-up rack moves left or right, the command is controlled by signals from the aligner installed at the front end of the take-up rack, ensuring the wire is always at the center position.

Φ1600/3150 Gantry-type Take-up Rack

- Adaptable reels: PN1600—PN3150

- Reel diameter range: Φ1600~Φ3500mm

- Adaptable reel width: 1300~2300mm

- Adaptable cable diameter: Φ10—Φ120mm

- Main take-up motor: 11kw/1450rpm AC variable frequency

- Take-up speed: 60m/min (max)

- Lifting power: 3Kw AC motor + cycloidal pinwheel reducer (2 sets)

- Clamping motor: 0.75kw AC motor + cycloidal pinwheel reducer (1 set)

- Cable arrangement motor: 2.2kw/1500rpm (AC variable frequency motor)

- Transmission method: 2.2Kw AC variable frequency motor + cycloidal pinwheel reducer

- Load capacity: 20T (max)

- Structure type: Gantry ground rail traveling type, upper sleeve type; gantry frame formed by bending and welding; the two centers of the reel are lifted by lead screws and nuts driven by two motors via cycloidal reducers; each center seat can be lifted individually or simultaneously, with dual mechanical and electrical protection devices; different specifications of center sleeves can be equipped if needed to meet the installation of different reel specifications; reel clamping is achieved via motor-reduction, with clamping overload protection; the take-up motor is a variable frequency motor, and the transmission method is that the motor drives the reel spindle to rotate via a 3-speed gearbox. The take-up motor is driven by a Siemens frequency converter. The cable arrangement adopts a high-speed ratio cycloidal reducer, driven by a 2.2kw AC variable frequency motor and frequency converter; when the cable arrangement reverses, the take-up rack stops for 3/4 of a circle before starting to move again; the cable arrangement pitch is set on the TD-400 display screen, and the cable arrangement pitch and tension can be set on the TD-400; the cable arrangement speed automatically tracks the take-up line speed; there are jog buttons for forward and reverse take-up; tension display and cable arrangement pitch display are provided.

Molding Die

| Die Type | Specification 1 | Specification 2 |

|---|---|---|

| Nylon Material | - | - |

Spare Tools

| No. | Specification | Quantity |

|---|---|---|

| 1 | Hexagon Socket Wrench | 1 set |

| 2 | Flat-head Screwdriver | 1 piece |

| 3 | Cross-head Screwdriver | 1 piece |

| 4 | Adjustable Wrench | 1 piece |

| 5 | Locking Pliers | 1 piece |

| 6 | Toolbox | 1 piece |

V. Main Accessory Brands

| No. | Accessory Name | Brand | Remarks |

|---|---|---|---|

| 1 | Programmable Logic Controller (PLC) | Siemens | - |

| 2 | Touch Screen | Weinview | - |

| 3 | Main Motor | Zhima | - |

| 4 | Driver | Inovance | - |

| 5 | Low-voltage Electrical Appliances | Chint/Schneider | - |

| 6 | Bearing | HRB/NTN/NSK/SKF | - |