Manufacturing process characteristics of wires and cables and their main production equipment

Main processes of wires and cables

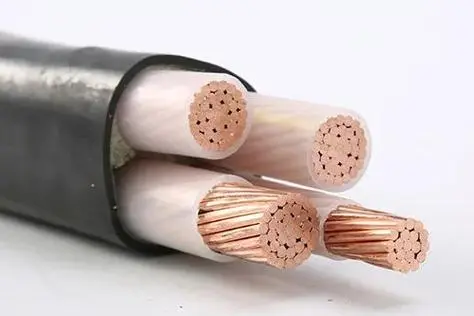

Wires and cables are made through three processes: drawing, twisting, and coating. The more complex the model and specifications, the higher the repeatability.

1. Drawing

In metal pressure processing, the metal is forced through a die (pressing wheel) under the action of external force, the metal cross-sectional area is compressed, and the technical processing method of obtaining the required cross-sectional shape and size is called metal drawing.

The drawing process is divided into: single wire drawing and twisted drawing.

2. Twisting

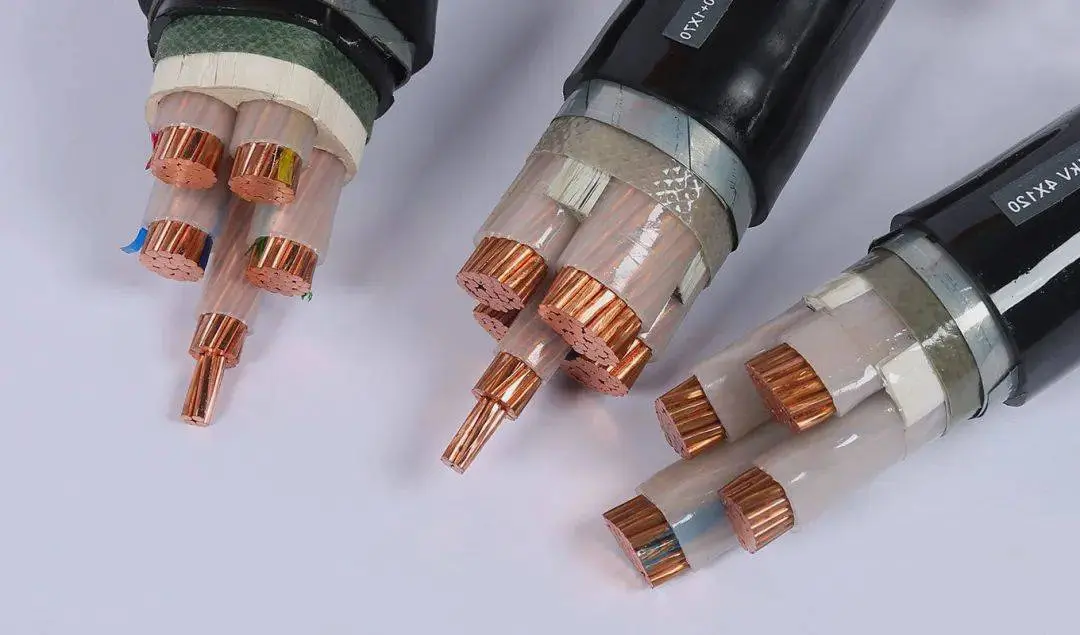

In order to improve the softness and integrity of wires and cables, two or more single wires are interwoven together in a specified direction, which is called twisting.

The stranding process is divided into: conductor stranding, cabling, braiding, wire armoring and winding.

3. Wrapping

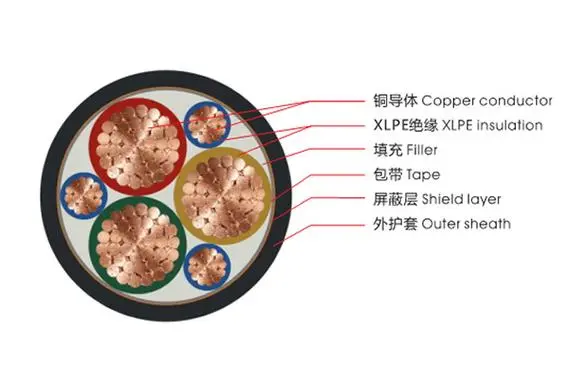

According to different performance requirements for wires and cables, special equipment is used to coat different materials on the outside of the conductor.

Coating process points:

- Extruded packaging: rubber, plastic, lead, aluminum and other materials.

- Longitudinal packaging: rubber, corrugated aluminum strip materials.

- Wrapping: ribbon-shaped paper tape, mica tape, alkali-free glass fiber tape, non-woven fabric, plastic tape, etc., and thread-shaped fiber materials such as cotton yarn and silk.

- Dip coating: insulating paint, asphalt, etc.

The manufacturing of wires and cables is completely different from the production of most electromechanical products. Electromechanical products are usually assembled into components, and then multiple components are assembled into a single product, and the products are measured by the number of units or pieces. Wires and cables are measured by length. All wires and cables start with conductor processing, and insulation, shielding, cabling, sheathing, etc. are added layer by layer on the outer periphery of the conductor to make wire and cable products. The more complex the product structure, the more layers are superimposed.

1. Cable production process characteristics

There are many categories of cable production processes and a large material flow. The manufacturing of wires and cables involves a wide range of processes, from the smelting and pressure processing of non-ferrous metals to chemical technologies such as plastics, rubber, and paint; textile technologies such as wrapping and weaving of fiber materials, to wrapping of metal materials and longitudinal wrapping of metal strips, welding of metal forming processes, etc. The various materials used in the manufacture of wires and cables are not only of many categories, varieties, and specifications, but also of large quantities. Therefore, the amount, spare amount, batch cycle, and batch size of various materials must be verified. At the same time, the decomposition, processing, recycling, reuse, and waste treatment of waste products are an important part of management. We should do a good job in material quota management and pay attention to conservation. In the production of wires and cables, from the entry and exit, storage of raw materials and various auxiliary materials, the flow of semi-finished products in each process to the storage and delivery of products, the material flow is large, and it must be reasonably laid out and dynamically managed.

Special equipment The manufacturing of many wires and cables uses special production equipment with the process characteristics of this industry to adapt to the structure and performance requirements of cable products and meet the requirements of long-length continuous and as high-speed production as possible, thus forming a series of special equipment for cable manufacturing. Such as extruder series, wire drawing machine series, stranding machine series, wrapping machine series, etc. The manufacturing process of wires and cables is closely related to the development of special equipment and promotes each other. New process requirements promote the generation and development of new special equipment; conversely, the development of new special equipment improves and promotes the promotion and application of new processes. Special equipment such as wire drawing, annealing, extrusion series line; physical foaming production line, etc., have promoted the development and improvement of wire and cable manufacturing technology and improved the product quality and production efficiency of cables.

2. Main processes of wires and cables:

Wires and cables are made through three processes: drawing, twisting, and coating. The more complex the model and specifications, the higher the repeatability.

- Drawing In metal pressure processing , the metal is forced through the die (pressing wheel) under the action of external force , the metal cross-sectional area is compressed , and the technical processing method of obtaining the required cross-sectional area shape and size is called metal drawing. Drawing processes are divided into: single wire drawing and strand drawing.

- Twisting In order to improve the softness and integrity of wires and cables, two or more single wires are interwoven together in a specified direction, which is called twisting. The twisting process is divided into: conductor twisting, cabling, braiding, steel wire armoring and winding.

According to the different performance requirements of wires and cables, special equipment is used to coat different materials on the outside of the conductor. The coating process is divided into:

Extruded packages: rubber, plastic, lead, aluminum and other materials.

Longitudinal package: rubber, corrugated aluminum strip material.

Wrapping: ribbon-shaped paper tape, mica tape, alkali-free glass fiber tape, non-woven fabric, plastic tape, etc., and linear fiber materials such as cotton yarn and silk.

Dipping: insulating paint, asphalt, etc.

3. Main production equipment of wires and cables

1. Necessary production equipment and testing equipment for overhead stranded wire products

|

Serial number |

Product Name |

Necessary production equipment and process equipment |

Necessary testing equipment |

|

1 |

Overhead stranded wire |

1. Wire drawing machine; 2. Wire twisting machine; 3. Aluminum clad steel wire continuous extrusion/continuous coating production line; 4. Aluminum alloy wire aging equipment; 5. Roller head die-piercing machine; 6. Welding equipment (annealing equipment should be provided when resistance welding is used); 7. Threading tube; 8. Parallel line mode; 9. Machine reels and delivery reels |

1. Conductor resistance tester; 2.Metal material testing machine 3. Wire winding tester 4. Adhesion test device 5. Zinc layer weight test device 6. Butterfly extensometer 7. Torsion testing machine 8. Precision balance 9. Vernier Caliper |

2. Necessary production equipment and testing equipment for enameled round winding wire products

|

Serial number |

Product Name |

Necessary production equipment and process equipment |

Necessary testing equipment |

|

1 |

Enameled round winding wire |

1. Wire drawing machine; 2. Wire drawing die; 3. Annealing furnace; 4. Paint mixing kettle; 5. Enameling machine; 6. Enamel mold; 7. Welding equipment (annealing equipment should be provided when resistance welding is used); 8. Machine reels and delivery reels |

1. Conductor resistance tester; 2. Elongation tester 3. Rebound tester 4. Softening breakdown tester 5. One-way paint scraper 6. Thermostat 7. Voltage tester 8. Winding test device 9. Oven 10. Magnifying Glass 11. Paint film continuity tester 12. Snap-off Tester 13. Peel tester 14.Solder tester 15. Thermal bonding test device 16. Refrigerant resistance test device 17.Metal tensile testing machine 18. No. 4 viscosity cup 19. Libra 20. Stopwatch 21. Micrometer |

3. Necessary production equipment and testing equipment for plastic insulated control cable products

|

Serial number |

Product Name |

Necessary production equipment and process equipment |

Necessary testing equipment |

|

3 |

Plastic insulated control cable |

1. Wire drawing machine; 2. Annealing furnace; 3. Wire harness machine 4. Plastic extruder; 5. Cabling machine; 6. Armoring machine; 7.Steel strip welding machine; 8. Metal textile looms; 9. Printing machine; 10. Printing wheel; 11. Cable making machine conductor mold; 12. Machine wire reels; 13. Delivery reels |

1. Conductor resistance tester; 2. AC voltage tester 3. Non-metallic material tensile testing machine 4. Chipper 5. Film processing machine 6. Projector 7. Spark machine |

4. Necessary production equipment and testing equipment for extruded insulated power cable products with rated voltage from 1KV to 35KV

|

Serial number |

Product Name |

Necessary production equipment and process equipment |

Necessary testing equipment |

|

3 |

Rated voltage 1KV to 35KV extruded insulation power cable |

1. Wire drawing machine; 2. Annealing furnace; 3. Wire twisting machine 4. Plastic extruder; 5. Cabling machine; 6. Armoring machine; 7.Steel strip welding machine; 8. Printing machine; 9. Printing wheel; 10. Machine wire reels; 11. Delivery reels |

1. Conductor resistance tester; 2. AC voltage tester 3. Partial discharge detection device for cable reels 4. Thermal extension test device 5. 200℃ air aging test chamber 6.Semiconductor resistance tester 7. Non-metallic material tensile testing machine 8. Chipper 9. Film processing machine 10. Projector |

5. Necessary production equipment and testing equipment for overhead insulated cables (1KV, 10KV, 35KV)

|

Serial number |

Product Name |

Necessary production equipment and process equipment |

Necessary testing equipment |

|

5 |

Overhead insulated cables (1KV, 10KV, 35KV) |

1. Wire drawing machine; 2. Annealing furnace; 3. Wire twisting machine 4. Plastic extruder; 5. Cabling machine; 6. Printing machine; 7. Printing wheel; 8. Machine wire reels; 9. Delivery reel |

1. Conductor resistance tester; 2. AC voltage tester 3. Partial discharge detection device for cable reels 4. Thermal extension test device 5. 200℃ air aging test chamber 6. Insulation resistance tester 7. Non-metallic material tensile testing machine 8. Chipper 9. Film processing machine 10. Projector 11. Tensile testing machine (10t) |

6. Product units, sampling units and models of wire and cable products

|

Serial number |

Product Unit Name |

Unit Name |

Implementation Standards |

|

|

1 |

Overhead stranded wire |

1 |

Aluminum stranded wire |

GB/T1179-1999 |

|

Steel core aluminum stranded wire |

||||

|

Anti-corrosion steel core aluminum stranded wire |

||||

|

2 |

Aluminum Alloy Stranded Wire |

|||

|

Steel core aluminum alloy stranded wire |

||||

|

Aluminum alloy core aluminum stranded wire |

||||

|

3 |

Aluminum Clad Steel Stranded Wire |

|||

|

Aluminum Clad Steel Core Aluminum Stranded Wire |

||||

|

Aluminum clad steel core aluminum alloy stranded wire |

||||

|

4 |

Steel strand |

|||

|

2 |

Enameled round winding wire |

1 |

Polyester enameled round copper wire |

GB/T6109.2-1990 GB/T6109.7-1990 |

|

2 |

High strength acetal enameled round copper wire |

GB/T6109.3-1985 |

||

|

3 |

Direct solderable polyurethane enameled round copper wire |

GB/T6109.4-1988 |

||

|

4 |

Polyester imide enameled round copper wire |

GB/T6109.5-1988 |

||

|

5 |

Polyimide enameled round copper wire |

GB/T6109.6-1988 |

||

|

6 |

Thermal or solvent bonded polyester enameled round copper wire |

GB/T6109.8-1989 |

||

|

7 |

Heat bonded or solvent bonded solderable polyurethane enameled round copper wire |

GB/T6109.9-1989 |

||

|

8 |

180 grade polyesterimide/polyamide composite enameled round copper wire |

GB/T6109.10-1989 |

||

|

9 |

200 grade polyesterimide/polyamideimide composite enameled round copper wire |

GB/T6109.11-1989 |

||

|

3 |

Plastic insulated control cable |

|

PVC insulated control cable |

GB9330-1988 |

|

4 |

Rated voltage 1kV and 3 kV extruded insulation power cable |

1 |

PVC insulated power cables with rated voltage of 1kV and 3kV |

GB/T12706.1-2002 Implementation Rules for Wire and Cable Production License Supplementary Technical Conditions (see Appendix 3) |

|

2 |

Rated voltage 1kV and 3kV cross-linked polyethylene insulated power cables |

|||

|

3 |

Rated voltage 1kV and 3 kV EPDM insulated power cables Rated voltage 1kV and 3 kV hard EPDM rubber insulated power cable |

|||

|

5 |

Rated voltage 6kV and 3 kV extruded insulation power cable |

1 |

Power cables with rated voltage of 6kV and 30 kV |

GB/T12706.2-2002 |

|

2 |

Rated voltage 35 kV power cable |

GB/T12706.3-2002 |

||

|

6 |

Overhead insulated cable |

1 |

1kV PVC overhead insulated cable |

GB12527-1990 |

|

2 |

10kV, 35kV overhead insulated cables |

GB14049-1993 |

||