Proposal for a plant with an annual output of 120,000 km of coaxial cables and 2,000 tons of PVC cable compounds

It is planned to invest approximately US$500,000 to rent a factory building and purchase new or second-hand refurbished copper-clad steel conductor production lines, physical foaming insulation extruders , magnesium-aluminum wire braiding machines , PVC outer sheath extruders, two-stage single-screw and double-screw mixing extruders and other production equipment.

Product plan table for this project

PVC cable material 2000 tons/year

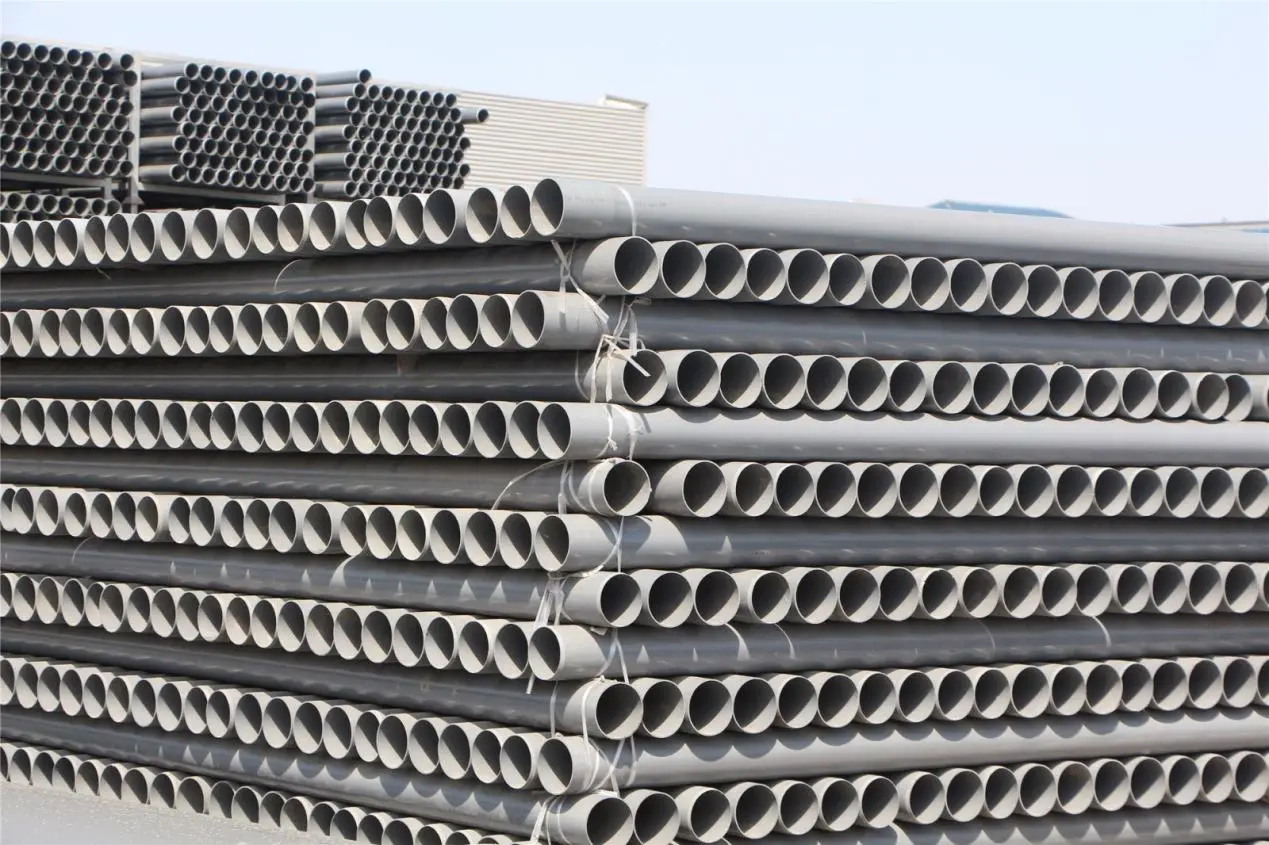

Coaxial cable 120,000 km/year

List of main production equipment of this project

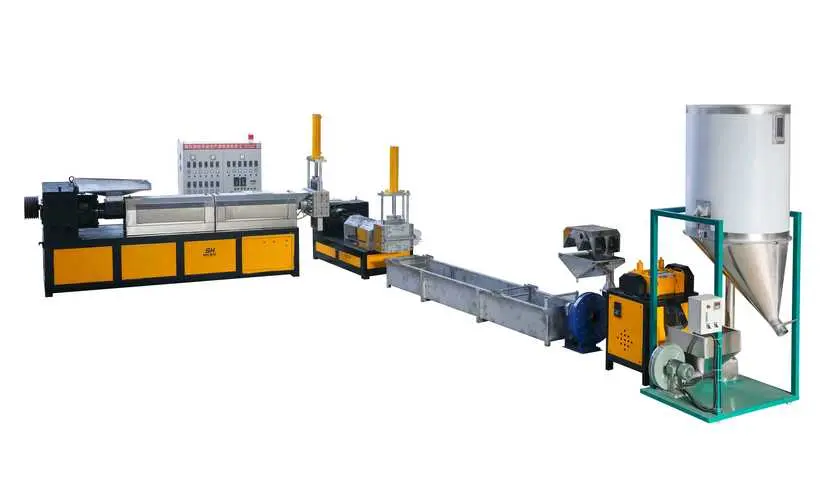

ONE. Annual production of 2,000 tons of PVC cable materials :

- SDJ75/180 twin-screw two-stage extruder unit , 1 set

- SJ90*28/SJ120*10 plastic granulator , 1 set

- 300L mixer , 1 set

- 4.900 type loader , 1 set

- Automatic feeding machine , 1 set

- Silo mixer , 1 unit

TWO. Annual production of 120,000 kilometers of coaxial cables:

1 65# foam insulation extruder , 4 sets

2 45# foam insulation extruder , 3 sets

3 16-spindle knitting machines , 35 units

4 24-spindle knitting machines , 5 sets

5 doubling machines , 8 sets

6 Loop forming machines, 3 units

7 Taping machines, 3 units

8 Cooling tower , 1 unit

Summary table of main raw and auxiliary materials for this project Unit: t/a

|

name |

Raw materials |

unit |

Total annual demand |

Maximum storage capacity

|

|

Annual production of 2,000 tons of PVC cable materials project |

PVC resin powder |

t/a |

930 |

10 |

|

Dioctyl phthalate |

t/a |

80 |

2 |

|

|

Calcium carbonate |

t/a |

800 |

10 |

|

|

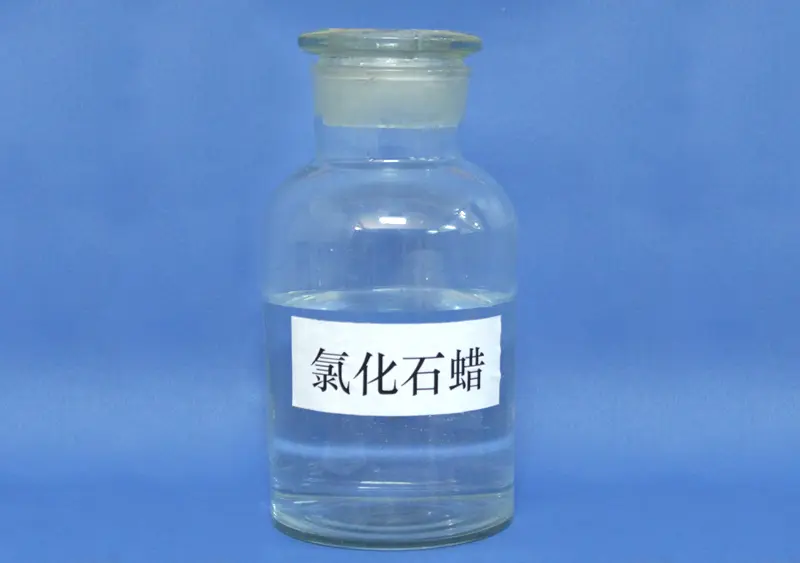

Chlorinated paraffins |

t/a |

135 |

5 |

|

|

Stearic acid |

t/a |

25 |

5 |

|

|

Kaolin |

t/a |

16 |

2 |

|

|

Antioxidants |

t/a |

0.5 |

0.2 |

|

|

Carbon Black |

t/a |

17 |

3 |

|

|

Pigment powder |

t/a |

1 |

0.2 |

|

|

Annual production of 120,000 kilometers of coaxial cable project |

Copper wire |

t/a |

100 |

10 |

|

Copper Clad Steel |

t/a |

200 |

20 |

|

|

Copper Clad Aluminum |

t/a |

80 |

20 |

|

|

Aluminum-magnesium alloy wire |

t/a |

30 |

10 |

|

|

Aluminum foil |

t/a |

10 |

2 |

|

|

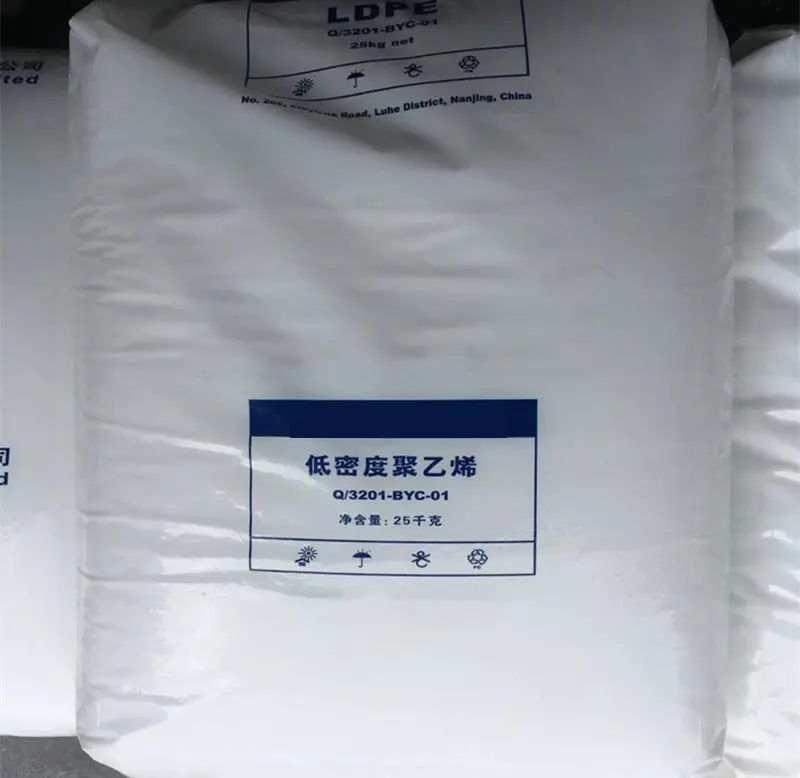

Polyethylene |

t/a |

300 |

5 |

|

|

Polyvinyl chloride |

t/a |

600 |

5 |

|

|

N2 foaming agent |

Bottle/year |

40 |

5 |

Physical and chemical properties:

- PVC resin powder Polyvinyl chloride, referred to as PVC in English, is a polymer formed by the polymerization of vinyl chloride monomer in the presence of initiators such as peroxides and azo compounds, or by the mechanism of free radical polymerization under the action of light or heat. It has stable physical and chemical properties, is insoluble in water, alcohol, and gasoline, and has low gas and water vapor permeability; it can withstand any concentration of hydrochloric acid, sulfuric acid below 90%, nitric acid of 50-60%, and caustic soda solution below 20% at room temperature, and has a certain degree of chemical corrosion resistance; it is quite stable to salts, but can be dissolved in organic solvents such as ether, ketones, chlorinated aliphatic hydrocarbons and aromatic hydrocarbons.

- PE (Polyethylene) Polyethylene, referred to as PE, is a thermoplastic resin obtained by polymerization of ethylene. In industry, it also includes copolymers of ethylene and a small amount of α-olefins. Polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance (the lowest operating temperature can reach -100~-70°C), good chemical stability, and can withstand the corrosion of most acids and alkalis (not resistant to oxidizing acids). It is insoluble in general solvents at room temperature, has low water absorption, and has excellent electrical insulation.

- PVC (polyvinyl chloride), polyvinyl chloride resin is a thermoplastic plastic with an amorphous structure. Under ultraviolet light, hard PVC produces light blue or purple-white fluorescence, while soft PVC emits blue or blue-white fluorescence. The refractive index is 1.544 at 20°C, the specific gravity is 1.40, and the density of products with plasticizers and fillers is usually in the range of 1.15-2.00, the density of soft PVC foam is 0.08-0.48, and that of hard foam is 0.03-0.08. It has no fixed melting point, starts to soften at 80-85°C, becomes viscoelastic at 130°C, and starts to change into viscous flow at 160-180°C; has good mechanical properties, tensile strength of about 60MPa, impact strength of 5-10kJ/m2; has excellent dielectric properties.

- Dioctyl phthalate (DOP)is a colorless oily liquid with a slight odor. Its main uses are as plasticizer, solvent, and gas chromatography stationary liquid. Its melting point is -40℃, boiling point is 340℃, and flash point is 218℃. It is flammable, stable, irritating, and difficult to dissolve in water. It is easily soluble in organic solvents such as methanol, ether, and carbon disulfide. It is mainly used in the processing of polyvinyl chloride resins, and can also be used in the processing of chemical fiber resins, acetate resins, ABS resins, rubbers, and other polymers. It can also be used in the production of paints, dyes, and dispersants.

- Chlorinated paraffin, chlorinated paraffin is a chlorinated derivative of paraffin hydrocarbons, with the advantages of low volatility, flame retardancy, good electrical insulation, low price, etc., can be used as a flame retardant and auxiliary plasticizer for polyvinyl chloride. It is odorless, non-toxic, and has good chemical stability. It is widely used in the production of cable materials, floor materials, hoses, artificial leather, rubber and other products.

- Calcium carbonate, short for heavy calcium carbonate, is a white powder, colorless and odorless. It is made by grinding natural carbonate minerals such as calcite, marble and limestone. It is a commonly used powdered inorganic filler with the advantages of high chemical purity, high inertness, low chemical reaction, good thermal stability, no decomposition below 400°C, non-toxicity and good dispersibility. It is stable in the air. It is almost insoluble in water and alcohol. It has been widely used in papermaking, plastics, plastic films, etc.

(7) N2 foaming agent . This product is a physical foaming agent. Nitrogen is low in cost, flame retardant and pollution-free, so it has a high application value. Moreover, physical foaming agents leave no residue after foaming, and have little effect on the properties of foamed plastics. However, it requires a special extruder and auxiliary equipment. The use requirements of this type of foaming agent are: its temperature and pressure must ensure that the foaming agent is mixed with the plastic in liquid form. When the temperature or pressure is changed, the foaming agent can be vaporized, that is, foaming begins. Its chemical name is nitrogen, and its molecular formula is N2. Under normal circumstances, it is a colorless, tasteless and odorless gas, and is usually non-toxic. Nitrogen accounts for 78.12% (volume fraction) of the total atmosphere and is the main component of air. It is a gas at room temperature. When cooled to -195.8℃ under standard atmospheric pressure, it becomes a colorless liquid. When cooled to -209.86℃, liquid nitrogen becomes a snow-like solid. The chemical properties of nitrogen are very stable. It is difficult to react with other substances at room temperature. However, under high temperature and high energy conditions, it can undergo chemical changes with certain substances and be used to produce new substances that are useful to humans.

Labor quota and production arrangement

The labor quota of this project is 20 people, and the production is carried out in three shifts of 8 hours, with an annual production day of 300 days.

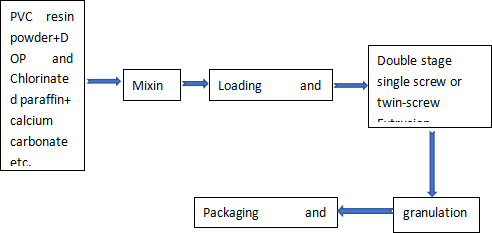

PVC cable compounds extruding process flow:

- Mixing: Mix PVC resin powder and other raw materials according to the product formula .

- Feeding and drying : After the raw materials are stirred and mixed, they are transported to the extruder through a closed pipeline. The equipment has its own heating device, the heating method is electric heating, and the feeding is automatic.

- Extrusion: The mixed raw materials are fed into the extruder. In order to fully mix the various ingredients, a special extruder is selected for the project.

- Pelletizing: Cut the extruded material into small pellets, some of which are used for subsequent coaxial cable product sheaths.

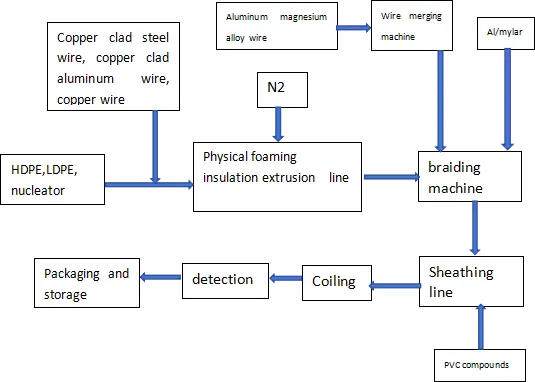

RG6 coaxial cable processing flow:

- Physical foaming extrusion: PE (polyethylene) is physically foamed with N2 and extruded with copper-clad steel or copper-clad aluminum on a physical foaming extruder production line.

- Wire drawing: It is the process of combining two or more single yarns into one strand, or combining two or more strands into one composite strand.

- Cooling: The products extruded by the core wire machine are directly cooled by cooling water before proceeding to the next step. The cooling water is not discharged, and the cooling water needs to be added regularly due to evaporation.

- High-speed weaving, sheathing, inspection and coiling: The cooled semi-finished products are woven by a high-speed weaving machine with aluminum foil, alloy wire, etc., and then sheathed with PVC (polyvinyl chloride). The products are then coiled, inspected, tested and put into storage.