Project Proposal for Annual production of 2000 tons of PVC sheathing compounds , 2000 tons of PE sheathing compounds , 1000 tons of PPR pipe compounds , 1000 tons of copper-clad aluminum-magnesium wir

The project plans to invest a total of US $ 300,000 to purchase second-hand refurbished twin-screw plastic granulator , copper-clad aluminum-magnesium wire drawing machine , aluminum-magnesium alloy wire drawing machine and other production equipment .

Table 1 Project product solution table

|

Serial number |

Product Solutions |

Total production |

|

1 |

PVC sheath material ( granulation processing) |

2000 tons /year |

|

2 |

PE sheath material ( granulation processing) |

2000 tons /year |

|

3 |

PPR pipe material ( granulation processing) |

1000 tons /year |

|

4 |

Copper clad aluminum magnesium wire (drawing) |

1000 tons /year |

|

5 |

Aluminum-magnesium alloy wire (wire drawing) |

500 tons/year |

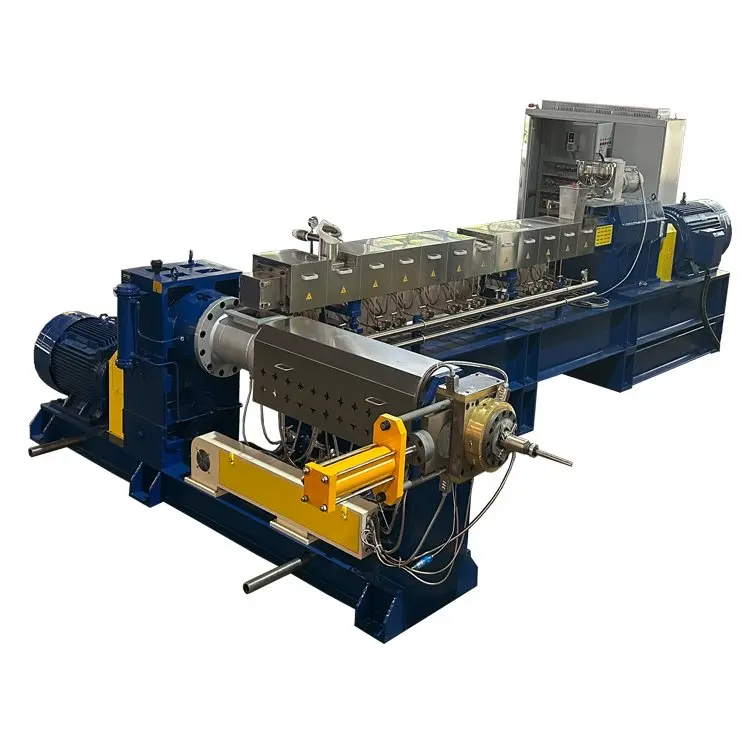

Table 2 List of main production equipment

|

Serial number |

Device Name |

Enterprise equipment after expansion Total quantity |

Specifications |

|

1 |

Double stage twin-screw extruder |

3 units |

65/150 type |

|

2 |

Double stage twin-screw extruder |

2 units |

75/180 type |

|

3 |

Mixing machine |

5 units |

1t |

|

4 |

Strong crusher |

1 unit |

30KW |

|

5 |

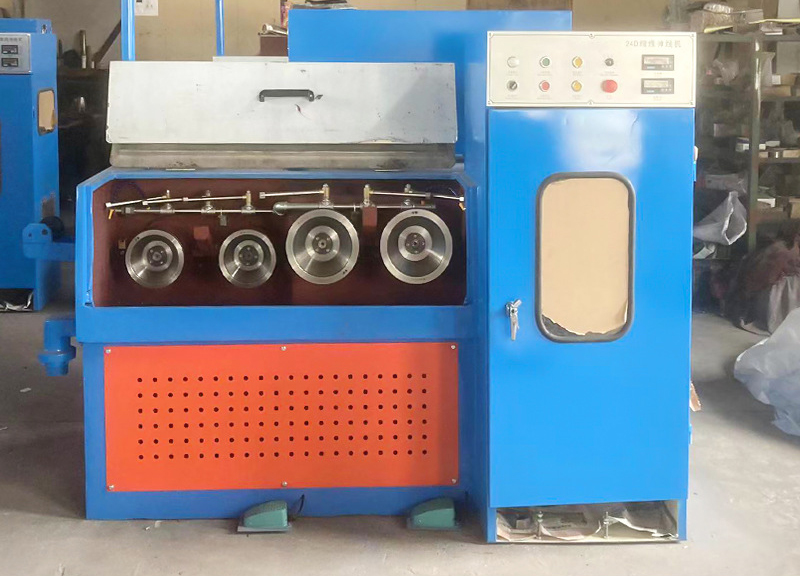

Rod Breakdown Machine |

2 units |

DF -12d |

|

6 |

InterMediate drawing machine |

4 units |

DF -17d |

|

7 |

Fine wire drawing machine |

24 units |

DF -24d |

|

8 |

Annealing furnace |

1 unit |

DF -40d |

65/150 Two-stage twin screw and single screw compounding extrusion granulation unit

75/180 Two-stage twin screw and single screw compounding extrusion granulation unit

Table 3 Main raw and auxiliary material consumption list

|

Serial number |

name |

Annual usage of enterprises |

Remark |

|

1 |

PVC plastic particles |

2000t/a |

Purchased, bagged |

|

2 |

PE plastic particles |

2000t/a |

Purchased, bagged |

|

3 |

PPR plastic particles |

1000t/a |

Purchased, bagged |

|

4 |

Copper clad aluminum magnesium rod |

1000t/a |

Purchased semi-finished products |

|

5 |

Aluminum-magnesium alloy rod |

500t/a |

Purchased semi-finished products |

|

6 |

Wire drawing oil |

2.5t/a |

Purchased, 200kg/barrel, liquid |

|

7 |

Iron spool |

1500pcs/a |

Outsourcing |

|

8 |

Carton |

60000pcs/a |

Outsourcing |

Physical and chemical properties of raw and auxiliary materials:

- PVC plastic particles:

short for polyvinyl chloride , a thermoplastic resin polymerized by vinyl chloride under the action of an initiator , is a homopolymer of vinyl chloride. It appears as a white powder, non-toxic and odorless. The relative density is 1.35-1.46, and the refractive index is 1.544 ( 20 °C ). It is insoluble in water, gasoline, alcohol and vinyl chloride, but soluble in solvents such as acetone, dichloromethane, and xylene. It has high chemical stability and good plasticity . Vinyl chloride homopolymers and vinyl chloride copolymers are collectively referred to as vinyl chloride resins. PVC is an amorphous structure with a low degree of branching. The molecular weight of industrially produced PVC is generally in the range of 50,000 to 120,000, with a large polydispersity, and the molecular weight increases with the decrease of polymerization temperature; it has no fixed melting point , begins to soften at 80 to 85°C, becomes a viscoelastic state at 130°C, and begins to change into a viscous flow state at 160 to 180°C; it has good mechanical properties, with a tensile strength of about 60MPa and an impact strength of 5 to 10kJ/ m2 . However, its heat resistance is poor, with a softening point of 80 °C . It begins to decompose and discolor at 130 °C , and precipitates HCI .

- PE plastic particles:

Polyethylene is a thermoplastic resin obtained by polymerization of ethylene . Non-toxic, odorless particles, milky white in appearance, density 0.86 ~ 0.96 g/ cm3 , melting point 92℃, boiling point 270℃, thermal decomposition temperature 270℃, poor water solubility. In industry, it also includes copolymers of ethylene and a small amount of α-olefins. Polyethylene is odorless, non-toxic, feels like wax , has excellent low temperature resistance (the lowest operating temperature can reach -70 ~ -100 ℃ ) , good chemical stability , can withstand most acid and alkali corrosion (not resistant to oxidizing acids) , is insoluble in general solvents at room temperature , has low water absorption , and has excellent electrical insulation properties .

- PPR plastic particles:

also known as random copolymer polypropylene (PPR), is a thermoplastic resin obtained by polymerization of ethylene . It is non-toxic, odorless, translucent and colorless solid, with a density of 0.92 g/ cm3 , a melting point of 164~170℃, a thermal decomposition temperature of 350℃, and poor water solubility. Its strength, stiffness, hardness and heat resistance are all better than those of low-pressure polyethylene , and it can be used at around 100 ℃ . Its products have good toughness, high strength, excellent processing performance, good creep resistance at higher temperatures, and have the unique high transparency of random copolymer polypropylene . It can be widely used in the production of pipes , sheets, daily necessities, packaging materials, household appliance components and various films.

(4) Raw and auxiliary materials of copper-clad aluminum magnesium and their physical and chemical properties:

Copper: Copper is a good conductor of electricity and heat. Its density is 8.96 g/cm³, its melting point is 1083.4℃, and it has good ductility and plasticity. Copper is chemically stable and not easily oxidized, but it will react with oxygen in a humid environment to form patina.

Aluminum: Aluminum is a lightweight metal with a density of 2.7 g/cm³ and a melting point of 660°C. Aluminum has good electrical and thermal conductivity, but is inferior to copper. Aluminum is chemically active and easily oxidized to form an aluminum oxide protective layer, which affects its electrical conductivity to a certain extent.

Magnesium: Magnesium is a lightweight metal with a density of 1.74 g/cm³ and a melting point of 650°C. Magnesium has good electrical and thermal conductivity and high specific strength, and is often used to enhance the strength and hardness of alloys. Magnesium is chemically active and easily reacts with oxygen, so surface treatment is often required in alloys to prevent oxidation.

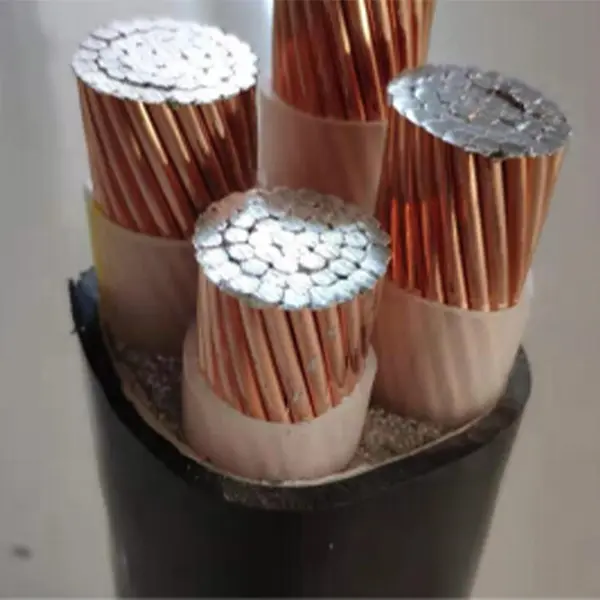

The physical and chemical properties of copper clad aluminum magnesium wire are as follows:

- Chemical composition: The chemical composition of copper-clad aluminum-magnesium is copper, aluminum and magnesium, of which the aluminum content is generally between 5% and 25%, and the magnesium content is generally between 1% and 10%1.

- Physical properties: Copper clad aluminum magnesium wire has relatively high strength and hardness while maintaining good electrical conductivity, thermal conductivity and corrosion resistance, and is suitable for occasions requiring higher material strength1.

- Mechanical properties: According to mechanical properties, it can be divided into soft state (A) and hard state (H), and according to the volume ratio of copper layer, it can be divided into 10% and 15%23.

- Copper clad aluminum magnesium wire is widely used in the following fields:

- Electric power industry: used for cables, transformers, etc.

- Electrical equipment: used for switches, etc.

- Electronic Communications: Used as conductors in high-frequency applications.

- Automobile, aviation, shipbuilding, railways: used for engines, water pumps, etc. 13.

(5) Physical and chemical properties of aluminum-magnesium alloy wire

Density: The density of aluminum is 2.7g/cm³, and the density of magnesium is about 1.8g/cm³, so the density of aluminum-magnesium alloy is between the two, usually less than 1.8g/cm³23.

Hardness: Magnesium alloys have low hardness and are usually improved through alloying technology.

Strength: Aluminum-magnesium alloys have high strength and corrosion resistance and are suitable for application scenarios that require high strength and corrosion resistance.

Processing performance: Aluminum-magnesium alloy wire has good processing performance and can meet complex forming processing requirements. It also has good weldability and surface treatment performance.

Application fields of aluminum-magnesium alloy wire

Aerospace: Used in aircraft fuselage structures, fuel tanks and engine parts, etc., due to its excellent strength and corrosion resistance, while also being able to reduce the overall weight of the aircraft1.

Automobile Manufacturing: Used in automobile body structures, engine components, and suspension systems to improve automobile fuel economy and driving performance1.

Electronic products: Used to manufacture electronic equipment components that require lightweight and high strength4.

Construction: Used for building structures that require high strength and corrosion resistance1.

General layout

This project uses the original factory building for expansion. The main gate of the factory building of this project faces north. On the north side of the factory building, from west to east, there are raw material storage area and finished product storage area; in the middle of the factory building, from west to east, there are small wire drawing machine, medium wire drawing machine, large wire drawing machine, annealing furnace; on the south side of the factory building, from west to east, there are crushers, mixers, two-stage granulation extruders, and cooling water pool facilities.

Labor quota and production days

After the expansion, the company has 20 employees, 300 working days per year, and 24-hour three-shift production.

Public works

(1) Water supply and drainage

Water supply: The water used in this project is supplied by the municipal water supply network .

Drainage: The drainage system of this project adopts the rainwater and sewage separation system .

(2) Power supply

The power supply for this project is provided by the local power supply station .

(3) Heating

production equipment and facilities of this project all use electricity as energy .

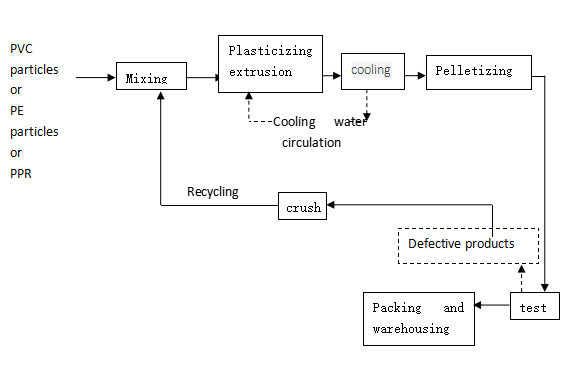

Production process

The specific production process is shown below.

- Production process of PVC sheath material, PE sheath material and PPR pipe material

Figure 1 Production process flow of PVC sheath material, PE sheath material and PPR pipe material

Main process flow:

(1) Mixing and stirring: Mix PE particles, PVC particles, PPR particles, crushed defective products from a crusher and other raw materials in proportion.

(2) Extrusion molding and cooling: The mixed raw materials are fed into the extruder through the feeding port, and then transported to the heating area for drying through the pipeline. The raw materials are placed in the extruder mold (electric heating, heating temperature 160 ℃ ~ 180 ℃ ), and irradiated by infrared high-temperature lamps to soften the plastic. Then compressed air is introduced into the semi-finished product to make the embryo close to the inner wall of the mold. After cooling and demolding, the finished sheath material or pipe material is obtained. After cooling, indirect cooling water is used for cooling. The cooling water is recycled and not discharged. Only evaporation loss needs to be replenished regularly.

(3) Pelletizing: Pelletize the plastic products as required.

(4) Inspection and crushing: The inspection process produces defective products, which are crushed by a crusher and then reused in the production process without being discharged.

of each process is carried out in a relatively closed space, and blowers and pipes are used to deliver semi-finished products to each process in turn .

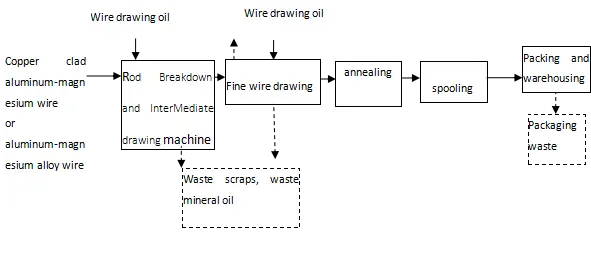

- Metal wire drawing production process

Figure 2 Metal wire drawing production process

Main process flow: The raw material copper-clad aluminum-magnesium wire or aluminum-magnesium alloy wire enters the large drawing machine, medium drawing machine and small drawing machine of different specifications for wire drawing. A small amount of wire drawing oil needs to be added during wire drawing. After wire drawing, it is annealed in the annealing furnace. The annealing temperature is 450℃~500℃, the annealing time is 5 seconds~10 seconds, and no oil mist is generated during the annealing process. After annealing, the product is coiled and packaged for storage .