Innovative Development of Advanced Manufacturing of New Materials for Metal Conductors

Abstract: High performance conductors need both strength and electrical conductivity. However, due to the inherent physical properties of metal materials, the strength and electrical conductivity are not well compatible. Therefore, it is necessary to sacrifice the strength of some metals to improve the electrical conductivity of alloys or metal-nonmetal composites. The advanced manufacturing technologies of new metal conductor materials or metal-nonmetal composites were reviewed. The existing and ongoing research achievements and industrial applications of metal conductor materials or metal-nonmetal composites at home and abroad in recent years were briefly reviewed. Finally, the development trend of metal-related materials was put forward.

As human civilization moves towards modernization, electrification, automation, informatization and networking, many application fields require that the materials used must have both high conductivity and high strength. For example, to produce high pulse magnetic fields, the required materials are not only required to have low resistivity and low thermal effect, but also to have sufficient strength to reduce thermal effect, and at the same time, their strength is required to be greater than 1 GPa and their conductivity is required to be greater than 34.8 mS/m. In 2017, the total consumption of copper and aluminum conductors in China was 6.7 million tons and 1.9 million tons respectively, of which the total consumption of electrical copper conductors accounted for about 1/3 of the corresponding international total and more than 60% of China's total copper consumption; the total sales output value of the wire and cable industry has reached 1.42 trillion yuan. In the large machinery industry, except for the automotive industry, the total consumption of copper conductors ranks second. In recent years, new materials, new processes, new technologies, new equipment and new products related to the advanced manufacturing of metal conductors have continued to emerge.

Metal conductor materials mainly include copper and copper alloy conductors, aluminum and aluminum alloy conductors, metal-metal, metal-nonmetal composite conductors, and special conductors. Among them, copper and copper alloy conductors mainly include copper-silver alloy wires and "Czochralski" single crystal copper; aluminum and aluminum alloy conductors mainly include film-wrapped and combined film-wrapped transposed rectangular aluminum stranded wires, aluminum and aluminum alloy cables, and Al-Mg-Si alloy wires; metal-metal, metal-nonmetal composite conductors mainly include improved composite core carbon fiber wires and aluminum-manganese alloy clad steel wires. ] A detailed introduction is given to Cu-Ag alloy wires, Al-Mg-Si alloy wires, and special conductors. On this basis, this article reviews the current status of research on other high-performance conductor contact wires.

1 Copper and copper alloy conductors

1.1 Development Status of Copper and Copper Alloy Conductors in my country

With the support of the Ministry of Science and Technology, the fire refining process of scrap copper (FRHC) rod manufacturing passed the acceptance of the Ministry of Science and Technology in 2014 and immediately became a key promotion project of the Ministry of Science and Technology. The FRHC rod can be used in the production of power cables, equipment cables, enameled wires and bare copper wires. At present, "FRHC rod" has become a special term in product standards, and has been included in the European standard, China's YS/T793-2012 industry standard, and the American standard drafted by the American Society for Testing and Materials. The FRHC direct rod manufacturing process, equipment technology and product quality have reached the international advanced level. The performance of the FRHC rod is shown in Table 1. The green environmental protection requirements have also met the national standards.

my country has independently developed an ultrafine grain reinforced copper-magnesium alloy contact wire. The contact wire can run at 350-410 km/h. Compared with similar international advanced products, its tensile strength is increased by 10%, its conductivity is increased by 5%IACS, its toughness is increased by 25%, and its contact network energy consumption is reduced by 5%. The procurement cost of similar products is reduced by 22%, and its price is more than 30% lower than that of foreign products. The manufacturing process of this product is an international first.

Tab. 1 Performance of FRHC bar

Cu-Ag alloy wire is a high-strength and high-conductivity conductor for overhead transmission lines. It can effectively increase the current carrying capacity of the conductor. The operating temperature can reach 150°C. Compared with the use of other high-temperature conductors (aluminum-zirconium heat-resistant aluminum alloy conductors), the transmission energy loss can be reduced by up to 40%.

The "Czochralski" single crystal copper manufacturing method is different from the "Ohno" continuous casting method developed in Japan. The single crystal copper manufactured by this method has a conductivity of up to 105.6% IACS. When used in video/audio cables, it can improve the signal transmission effect.

The oxygen-free copper strip manufactured by the "grain growth control" technology has excellent heat resistance. With the technological innovation of electric vehicles, hybrid vehicles, wind power and photovoltaic power generation, the high output of power components such as automobile engine control and power conversion will help improve the bonding performance between the power component substrate and peripheral components.

1.2 Application and large-scale production of single-crystal copper wire made by the “Czochralski” method in video/audio cables

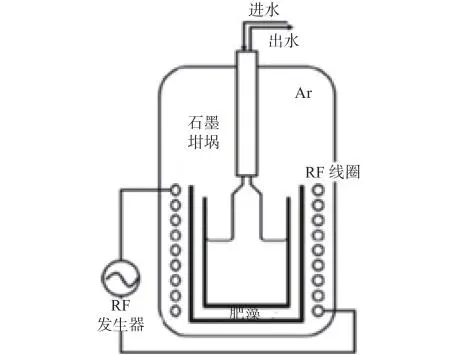

The "Czochralski" melt crystal growth method is a method for growing high-quality single crystals from a melt and is also one of the most common single crystal growth methods. Its main features are that it can quickly pull large-sized single crystals and the crystal growth direction is easy to control [ 15 ] . The relevant crystal growth process is shown in Figure 1.

Fig. 1 Schematic diagram of the crystal growth system

Figure 2 is a photo of single-crystal copper (SCC) grown by the "Czochralski" melt crystal growth method. SCC wires made by the "Czochralski" method can reduce resistivity and improve signal transmission, and are widely used in video/audio cables.

Fig. 2 Picture of the single-crystal copper

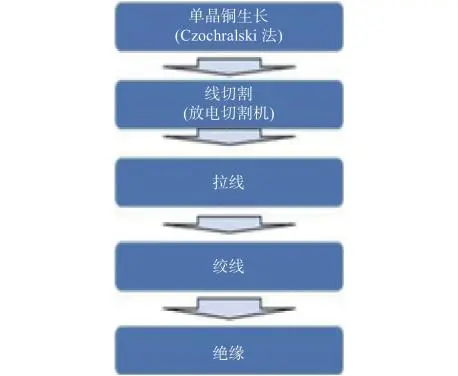

Figure 3 shows the cable preparation process.

Fig. 3 Whole process of cable manufacturing

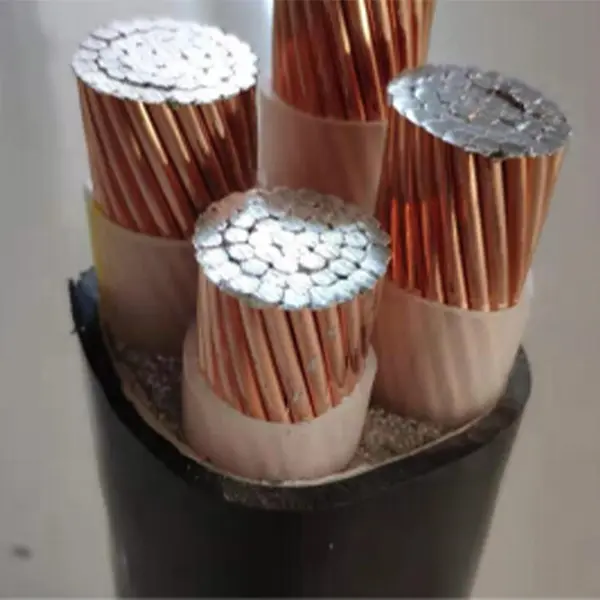

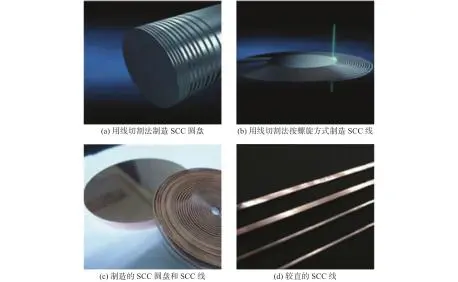

Figure 4 shows a video/audio cable made of SCC conductors. SCC is prepared by the "Czochralski" method, and SCC discs and SCC wires are produced by wire cutting ( as shown in Figure 5). After wire drawing, stranding, and insulation protection, cables for video/audio are prepared.

Fig. 4 Vedio/audio cable made of SCC conductor

Fig. 5 SCC disks and SCC wires making and made by wire-electrode cutting method

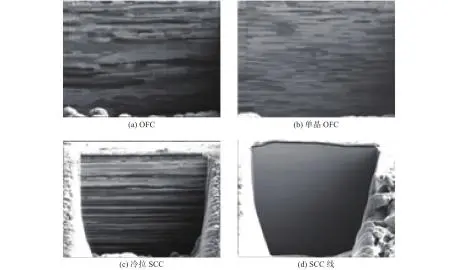

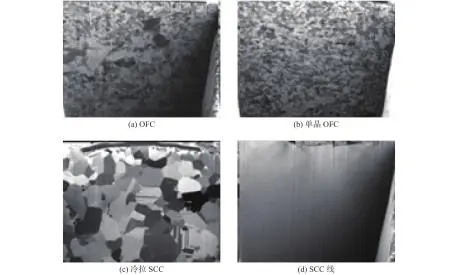

Figure 6 shows the microstructure of oxygen free copper (OFC), single crystal oxygen free copper, SCC after cold drawing, and the longitudinal cross section of the SCC wire after wire cutting.

Fig. 6 Longitudinal section focus ion beam scanning electron microscope images of the 4 types of copper alloys after wire-electrode cutting

FIG. 7 shows the lateral interface microstructure of the above materials.

Fig. 7 Cross-section focus ion beam scanning electron microscope images of the 4 types of copper alloys after wire-electrode cutting

Table 2 shows the resistivity of four different types of copper materials. As shown in Table 2 , the resistivity of SCC wire is the smallest, which is 1.5945×10 −8 Ω·cm (conductivity is 105.6 %IACS). Therefore, cables made of SCC wire have better performance and show better characteristics in video/audio cables.

Tab. 2 Resistivity and electric conductivity of different types of copper materials

2 Aluminum and aluminum alloy conductors

2.1 Current status of aluminum and aluminum alloy conductor development in China

The world's first ±1100 kV DC UHV transmission project, which runs from Zhundong, Xinjiang to southern Anhui, with a total length of 3,324 km, increased its transmission capacity to 12 million kW, and extended its economic transmission distance to more than 3,000 km, was completed at the end of 2018, creating a technical foundation for cross-border interconnected power transmission. China 's 1,000 kV and ±800 kV AC and DC transmission lines and their conductors are already at the international leading level. Secondly, membrane packages and combined membrane packages are used in high-voltage, ultra-high-voltage and ultra-high-voltage transmission lines, and may be used in high-speed flying trains. It is reported that China will reduce the fuel consumption of each new passenger car to 4 L per 100 kilometers by 2025. With the development of lightweight, electrification and pollution reduction of automobiles, aluminum and aluminum alloy cables for vehicles are indispensable products. The draft of the new standards ISO/DIS 19642-4, 6, 8, 10 of the International Organization for Standardization has been published, which will help promote the development of China's automobile industry. Highly conductive, ultra-high conductive and ultra-ultra-high conductive Al-Mg-Si alloys have been successfully developed and standardized in Europe, which is conducive to user selection and reduces the transmission loss of overhead transmission lines. ZnAl15 alloy is first made into 12 mm rods and 1.2-6.4 mm wires, and then sprayed onto parts or moving objects by hot spraying. Its anti-corrosion effect is much better than that of hot-dip galvanizing. ZnAl15 alloy rods can be made using existing up-drawing continuous casting machines. Heating treatment can effectively increase its elongation, so as long as it first passes a certain degree of hot deformation and then realizes cold deformation wire making, it is feasible. Fine wires made of Al-Mg-Si-Mn-Ni alloy have high strength and impact resistance, and have appropriate elongation and conductivity. They are suitable for use in industrial equipment and other occasions, which can reduce weight and save costs. Adding Mn can refine the grains and increase the elongation; adding Ni can inhibit the decrease in elongation and improve strength, thereby obtaining high impact resistance. Low temperature aging treatment can bring the tensile strength and elongation to a higher level.

2.2 Membrane package and combined membrane package transposition rectangular aluminum stranded wire

Film-wrapped and combined film-wrapped rectangular aluminum stranded wires have been successfully applied to winding coils in various dry-type smoothing reactors for special, ultra-high, and high-voltage transmission lines such as ±800 kV, ±500 kV DC and 1100 kV AC, and may be expanded to reactors in lower voltage level lines, and may also be used for coils for inductive wireless charging on high-speed flying trains. This combined film-wrapped transposed rectangular aluminum stranded wire can meet the needs of large current carrying capacity.

Features of film-wrapped rectangular aluminum stranded wire: 1) It has the advantage of complete transposition; 2) The single wire is only deformed normally during twisting, without other irregular variations; 3) There is no short-circuit point between all the insulated single wires after twisting, which greatly improves the skin effect, reduces eddy current loss, and has good uniform electrical performance.

2.3 Aluminum and aluminum alloy cables

Aluminum and aluminum alloy automotive cables for road vehicles have been published in the International Organization for Standardization standard (ISO/DIS 19642-4, 6, 8, 10-2017). This standard will add momentum to the innovative development of China's automobile lightweighting, electrification, pollution reduction and cable production. The current national standard is 12 years behind the International Organization for Standardization standard. The International Organization for Standardization standard specifies not only copper cables but also aluminum and aluminum alloy cables, as shown in Tables 3 and 4 .

Tab. 3 Performance of each single strand after annealing

Tab. 4 Conductor resistance and cross-sectional area

3 Metal-to-metal, metal-to-nonmetal composite conductors

Al-Mn alloy clad steel wire replaces aluminum clad steel wire, which can increase the service life of transmission lines (especially in areas with severe salt spray). Al-Mn alloy clad steel wire has entered the trial stage in Japan. The improved composite core carbon fiber conductor independently developed by China has been successfully developed and passed the appraisal at the new product technology appraisal meeting organized by the China Electricity Council. The improved new conductor has been put into trial operation on the 10, 35, 110 kV and 330 kV overhead transmission and distribution lines of the State Grid Shandong and Ningxia companies.

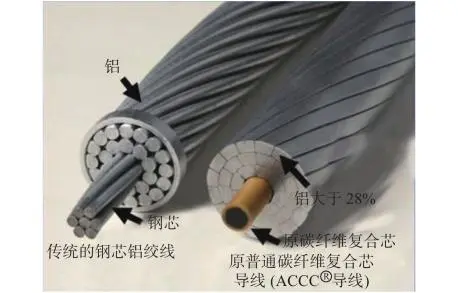

3.1 Improved composite core carbon fiber conductor 3.1.1 Features

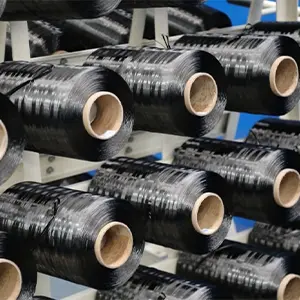

The improved composite core carbon fiber conductor uses coated conductor technology to achieve effective stress treatment of the carbon fiber core. The improved conductor avoids the sharp corner phenomenon that the conductor may experience during abnormal construction, and effectively utilizes the prestressing treatment of the composite core rod, greatly improving the ability to resist bending damage and ensuring the safety of line operation; the composite core is completely covered and isolated, no longer affected by environmental factors, ensuring the safe operation of the line; the conductor coating layer avoids the direct compression of the composite core, and the coated core can be constructed with ordinary hardware and ordinary methods like the steel core of the ordinary conductor, which is safely matched and greatly reduces the cost of the project (hardware and construction); the performance of the carbon fiber conductor is further improved (the current carrying capacity is increased, the transmission efficiency is increased to more than 40%, the strength and elastic modulus of the core rod and the conductor are greatly increased, and the sag problem of the ice area and the large span large conductor is effectively solved; the bending stiffness of the load-bearing core and the conductor is improved, and the wind resistance and anti-dancing ability of the conductor are improved); intelligent manufacturing technology (mature means such as eddy current, X-ray, laser, etc., online monitoring without blind spots) can be widely adopted, and the supervision and quality tracing management mechanism of each centimeter section of the coated core is realized, ensuring the quality of the conductor manufacturing link. The improved composite core carbon fiber conductor is shown in Figure 8.

Fig. 8 Improved composite core carbon fiber conductor

The improved composite core carbon fiber conductor is an improved technical implementation that satisfactorily solves all the defects of carbon fiber conductors. The technology has independent patent protection and can be widely promoted and applied. It is internationally leading and has patent protection worldwide.

3.1.2 Key performance

The key properties of the improved composite core carbon fiber conductor include: the strength is further increased to 3500 MPa; the core rod density is further reduced to 1.6 g/cc; the thermal expansion coefficient is further reduced to 0.06×10-6 / ℃; the elastic modulus is restored to 165 GPa; the improved composite core carbon fiber conductor/core has better bending ability, the diameter of the composite core wire drum before coating is 1.4 m, and the diameter of the composite core wire drum after aluminum coating is 0.8 m. Table 5 gives the improved and Comparison of application technologies of ordinary carbon fiber composite core conductors (ACCC conductors).

Tab. 5 Comparison of the application technology between modified and common carbon fiber composite core conductors (ACCC conductors)

3.1.3 Prospects for promotion and application

In recent years, urban development has been changing with each passing day, and the contradiction between urban power load supply and demand has become a contradiction that cannot be ignored. Therefore, in order to solve the practical problems of urban land use difficulties and many obstacles in new transmission channels, it is urgent to vigorously promote the application of new conductors. On the basis of ordinary carbon fiber composite core conductor, the conductor performance and hardware performance are further optimized, the construction cost is reduced, and the construction process is optimized to ensure the safety of the construction process, eliminate the potential safety hazards in line operation, and reduce the cost of later operation and maintenance. The amplitude is reduced, the economic benefit ratio is high, and it has broad application prospects in new construction of lines and renovation of old lines.

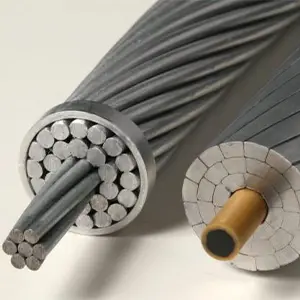

3.2 Al-Mn alloy clad steel wire

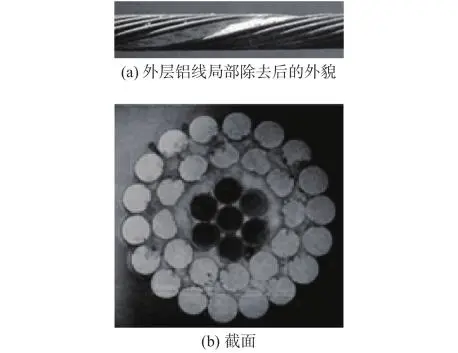

Al-Mn alloy clad steel wire has been put into trial operation on overhead transmission lines in an effort to improve the safety and reliability of overhead transmission lines and extend the service life of conductors. The current status of conductor corrosion on actual overhead transmission lines is shown in Figure 9. As can be seen from Figure 9 , most of the corrosion of the conductor occurs on the internal aluminum wire, and there are more corrosion products inside the conductor.

Fig. 9 Aluminum conductor steel reinforced wire examples corroded by salt spray obtained from practical transmission lines

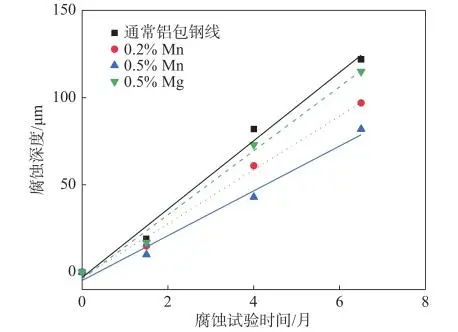

The curves of corrosion depth of Al-Mn and Al-Mg alloy clad steel wire (diameter 2.6 mm) over time are shown in Figure 10. By comparison, it is found that the new aluminum alloy material containing 0.5% Mn by mass is the most suitable wire material for cladding steel wire. Its corrosion resistance is 1.6 to 2.0 times higher than that of steel core aluminum stranded wire. It is currently being tried and promoted.

Fig. 10 Corrosion depth curves of Al-Mn and Al-Mg alloy clad steel wires

4 Conclusion

It is contradictory for metal conductor materials to have both high strength and high conductivity. New conductor materials can be obtained by properly balancing the two. There are usually four ways:

1) Highly purified materials;

2) Material alloying;

3) Application of graphene (preparation of single-layer graphene nanoribbons, used as positive electrode materials for primary batteries), carbon nanotubes (preparation of metallic hydrogen, which may produce room-temperature superconductors) and stanene, etc.;

4) Develop composite materials.