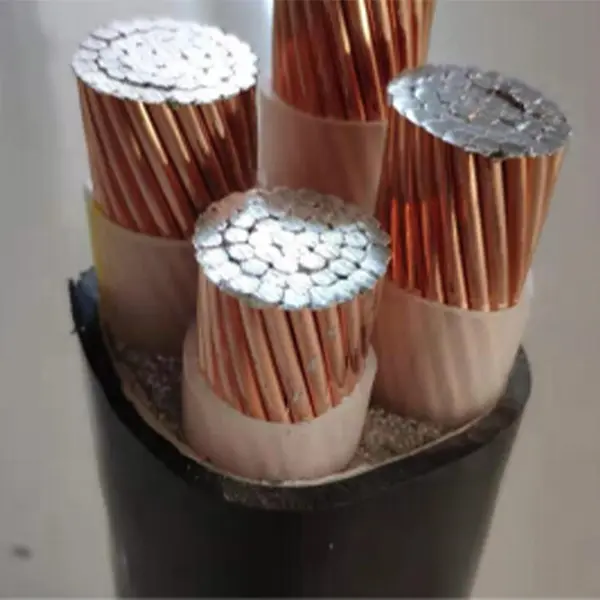

And examples of low-smoke and low-halogen PVC cable materials

The development of flame-retardant, low-smoke, low-halogen polyvinyl chloride (PVC) cable material is introduced. By changing the dosage of aluminum hydroxide (AL(0H)3,), antimony trioxide (Sb2O3), zinc borate (2ZnO·3B2O3·5H2O), etc., the flame retardant effect and smoke emission of PVC cable material are observed. The changes in its mechanical and electrical properties are combined to finally determine the best combination and ratio of flame retardants.

Flame-retardant cables can be divided into general flame-retardant cables, low-halogen flame-retardant cables, low-halogen low-smoke cables and halogen-free low-smoke cables according to the halogen gas release and smoke volume produced during combustion. Low-halogen low-smoke cables produce less corrosive gas and very little smoke during combustion, which can reduce the disaster and loss caused by cable combustion to a minimum in fire accidents, that is, solve the "secondary disaster" caused by cable combustion. At present, the cables used in some important places in developed countries are gradually tending to low-smoke and low-halogen and halogen-free low-smoke types, such as subways, airports, high-rise buildings and nuclear power plants. my country's wire and cable industry has also included halogen-free low-smoke cables in the "Ninth Five-Year Plan" key development wire and cable varieties. This paper mainly studies the low-smoke and low-halogen formula design of PVC cable materials.

Experimental part

1.1 Raw materials

PVC (S-1000), Qilu Petrochemical Company Chlor-alkali Plant; dioctyl phthalate (DOP), industrial grade, Jinan Yuxing Chemical General Plant; dioctyl terephthalate (DOTP), industrial grade, commercially available; chlorinated paraffin (containing 70% chlorine), commercially available; A1(OH)3 (1200 mesh), Shandong Aluminum Plant; Sb203, commercially available; light CaCO3, Zibo Shuangfeng Group; PbSt2, Qingdao Red Star Chemical Group; zinc borate, commercially available.

1.2 Test equipment and model

High-speed mixer, GH-10A, Beijing Plastic Machinery Factory; double-roll plasticizer, SK-160B, Shanghai Rubber Machinery Factory; flat vulcanizer, QLB-D, Qingdao Chemical Institute Machinery Factory; tensile testing machine, LI-1000, Guangzhou Material Testing Machine Factory; Shaw hardness tester, XHL, Shanghai Liuzhong Measuring Instrument Factory; oxygen index tester, HC-2, Nanjing Jiangning Instrument Factory; volume resistance meter, ZC-36, Shanghai Sixth Electric Meter Factory.

1.3 Process flow and process conditions

1.3.1 Process flow

1.3.2 Process conditions

(1 ) Ingredients: The proportion of various materials is by mass.

(2) Plastication: The roller temperature of the open mill should be strictly controlled to prevent the decomposition of the material and affect the performance. In the experiment, the temperature of the front roller was 1550°C and the temperature of the rear roller was 1500°C, so that the material wrapped the front roller. The plastication time was the same for multiple sample preparation ingredients.

(3) During molding, the temperature should not be too high and the preheating should be sufficient. During the tableting process, the exhaust should be sufficient to ensure that there are no bubbles inside the material. The time and pressure of molding multiple samples are the same. During the test, the preheating pressure is 5MPa, the temperature is 165oC, and the pressure is 10MPa.

(4) After the sample is parked for 16 hours, the performance test is performed again to eliminate internal stress.

1.4 Test Standards

Tensile strength shall be carried out in accordance with GB1040-92; elongation at break shall be carried out in accordance with GB1040-92; hardness (Shore A) shall be carried out in accordance with GB2411-89; oxygen index shall be carried out in accordance with GB2406-93; volume resistivity shall be carried out in accordance with GB1410-89.

1.5 Basic recipe

PVC, 100; DOP, 20; DOTP, 20; Chlorinated paraffin, 15; Trisalt, 4; Disalt, 3; HSt, 0.5; Paraffin, 0.5; CaCO3, 30; Sb2O3, 5; AI(OH)3 50; Zinc borate, 5.

Results and Discussion

2.1 Effect of aluminum hydroxide dosage on system performance

As the amount of aluminum hydroxide added increases, the oxygen index gradually increases, as shown in Table 1. During the combustion process, it was observed that as the amount of aluminum hydroxide added increases, the amount of smoke produced by the system decreases, and the color of the smoke changes from black to white. Al(OH)3, when heated, will undergo dehydration and decomposition.

It releases crystal water and absorbs a large amount of heat, thereby reducing the temperature of the polymer surface, delaying the thermal degradation rate of the polymer, slowing down or inhibiting the combustion of the polymer, and promoting carbonization and smoke suppression. In addition, the large amount of water vapor released can dilute the concentration of combustibles, reduce the contribution of combustible combustion, and reduce the heat release and smoke generation of the system, which also greatly helps to interrupt combustion, prevent polymer combustion, and achieve the purpose of flame retardancy.

With the increase of Al(OH)3, the tensile strength of the system decreased significantly, and the elongation at break also decreased. This is because (OH) is an inert filler that cannot combine well with the raw materials and form an interface inside the system, thereby reducing the mechanical properties. The increase in hardness is due to the fact that Al(OH)3 is a rigid particle and acts as a filler in the system, causing the hardness to increase.

2.2 Effect of Sb2O3 dosage on system performance

As the amount of Sb2O3 added increases, the oxygen index of the material has a significant increasing trend, see Table 2 for details. During the experiment, it was also found that with the increase of Sb2O3, the amount of smoke also increased, and black smoke was emitted, indicating that Sb2O3 only plays a flame retardant role, and the effect on smoke suppression is relatively small. When the halide is decomposed by heat to release hydrohalic acid and halogen elements, it reacts with Sb2O3 to form antimony trihalide and antimony halogen oxide. Antimony trihalide reacts with plastic to generate carbon, and the carbonized layer formed acts as a heat shield for the plastic below, preventing combustion.

The tensile strength of the system increases first and then decreases. This is because when the amount of Sb2O3 added is small, the number of Sb2O3 particles is small, its dispersion is better, and it plays a reinforcing role. At this time, the tensile strength increases with the increase of content; but when the Sb2O3 content continues to increase, the number of inorganic particles in the system increases, and it cannot be well infiltrated by the plasticizer, and the contact angle with the material is relatively large, resulting in uneven distribution in the system, weakening the adhesion of the two-phase interface, and reducing the mechanical properties of the system material. The volume resistivity of the system does not change much.

2.3 Effect of zinc borate dosage on system performance

2.3.1 Combustion performance

As can be seen from Figure 1, as the amount of addition increases, the oxygen index gradually increases. During the experiment, it was also found that as the amount of zinc borate increases, the amount of smoke during combustion decreases significantly, and the color of the smoke gradually turns white. Zinc borate is a fine crystalline powder with good dispersibility, which is easy to disperse in various resins. When used together with Sb203, it improves the flame retardancy. Because zinc borate releases a large amount of crystal water when it burns, it absorbs a lot of heat and delays the temperature of the polymer.

The speed of temperature rise. At the same time, the water vapor released dilutes the combustion gas, and the B2O3 finally formed forms a glassy film covering the polymer, isolating oxygen and playing a flame retardant role. Boron compounds are flame retardants in the flame phase and solidification phase. Under combustion conditions, PVC produces HCl, which reacts with zinc borate to form non-volatile zinc compounds. When used in combination with antimony trioxide, the oxygen index can be increased and the generation of smoke can be suppressed.

2.3.2 Mechanical properties

As can be seen from Figure 2, with the increase of the addition amount, the tensile strength and elongation at break of the system gradually decrease. This is because

Zinc borate is a filled flame retardant. Its shape is quite different from that of PVC molecules and it cannot be well wetted by plasticizers, so its compatibility is poor. As its dosage increases, many interfaces are formed in the system, which are easy to slip under the action of external forces, resulting in a decrease in mechanical properties.

2.3.3 Effect of zinc borate dosage on hardness and volume resistivity

As can be seen from Figure 3, with the increase of the added amount, the hardness and volume resistivity of the system increase to varying degrees. Because it is an inorganic filled flame retardant like Sb203, it plays a filling role in the system. The reason for this is the same as that of antimony trioxide.

Conclusion

(1 ). AI(OH) has good flame retardant and smoke suppression effects. In this test, the optimal dosage is 60 parts.

(2). Zinc borate can work synergistically with Sb203 to make the flame retardant effect more significant and significantly reduce the amount of smoke.

(3). From the experiments, it can be concluded that the optimal formula of low smoke and low halogen cable materials is as follows:

PVC,100;DOP, 20;DOTP,20:chlorinated paraffin,15;trisalt,4;disalt,3;HSt,0.5;paraffin,0.5;CaCO3,30;Sb203,5;Al(OH)3, 60; Zinc borate, 5.

BASIC KNOWLEDGE OF PVC CABLE MATERIAL FORMULA DESIGN AND EXAMPLES OF PRODUCTION FORMULAS

PVC cable material is composed of polyvinyl chloride resin, stabilizer, plasticizer, filler, lubricant, antioxidant, colorant, etc. The withstand voltage and insulation resistance of PVC cable material are relatively high, but the dielectric constant and dielectric loss are relatively large. Therefore, it is generally used as the insulation layer of low voltage (≤1KV) and medium and high voltage (6~10KV) cables. PVC plastic is also widely used as the sheath material of wires and cables because of its flame retardancy, oil resistance, corona resistance, chemical corrosion resistance and good water resistance. By adding special performance additives or modifiers, heat-resistant (105℃), cold-resistant, oil-resistant, flame-retardant, super soft and non-toxic PVC cable materials can be manufactured to meet the needs of special wire and cable products.

Cable materials are among the varieties with higher performance requirements in PVC formulations , especially electrical insulation, low temperature resistance and aging resistance. These special requirements must be considered when designing the formulation.

PVC cable materials can be divided into two types: sheath grade and insulation grade. The sheath grade requires good heat resistance, while the insulation grade requires good insulation.

each component are as follows

PVC resin

It requires high molecular weight and easy absorption of plasticizer, so the suspension loose PVC resin is selected. In addition, low-grade resin with high purity, few impurities and few fish eyes should be selected, generally SG-1 or SG-2. At present, some manufacturers also choose SG-5 type resin, but in principle it is not recommended. At present, due to the shortage of type 1 and 2 resins, many cable materials use SG-3 type PVC resin. SG-1 type resin should be used for high-grade electrical insulation materials, and SG-2 and 3 types can be used for general electrical insulation materials. Cable materials with high heat resistance requirements should use SG-1 type.

Plasticizer

The plasticizer content is generally around 50PHR, and the highest is up to 60PHR. Usually, varieties with good heat resistance and electrical insulation are selected, such as DOP. DOS and DOA can be added to improve cold resistance, and trioctyl trimellitate can be added to improve heat resistance. The combined use of several plasticizers often has a good effect. In actual cable material formulas, plasticizers are generally used in combination.

For cable materials with high electrical insulation, phosphate esters can be used as the main plasticizer, while phthalates can be used as the main plasticizer for general-purpose grades. Chlorinated paraffin can improve electrical insulation. Fatty acid esters and epoxy plasticizers can improve the low-temperature resistance of cable materials, and the latter also has good weather resistance.

The volatility resistance and heat resistance of plasticizers are the key to determining the high temperature resistance of cable materials. For cable materials with a temperature resistance of 70°C, plasticizers such as diisodecyl phthalate (DIDP) or diisononyl phthalate (DINP) can be used. For cable materials with a temperature resistance of 90°C, diundecyl phthalate and ditridecyl phthalate should be used. For cable materials with a high temperature resistance of 105°C, plasticizers with higher heat resistance, such as trioctyl trimellitate (TOTM), should be used.

The acid value of the plasticizer affects the electrical insulation and heat resistance of the cable material, so a plasticizer with a smaller acid value should be selected. The molecular weight and flash point of the plasticizer affect the heating loss of the cable material, so a plasticizer with a higher flash point and a larger molecular weight should be selected. For example, compared with dioctyl phthalate, dioctyl adipate and dioctyl sebacate, the former has a smaller molecular weight and a lower flash point, so the heating loss is also larger.

When selecting a plasticizer, its plasticizing efficiency should also be considered. Selecting a plasticizer with a higher plasticizing efficiency can reduce the amount of plasticizer in the formula. The amount of plasticizer is related to the insulation performance, and reducing the amount of plasticizer is beneficial to improving the insulation performance.

Stabilizer

Basic lead salt is used as the main stabilizer, and generally multiple stabilizers are selected for use in combination to exert a synergistic effect to improve thermal stability. Tribasic lead sulfate and dibasic lead phosphite are used together to take into account thermal and light stability. The main stabilizer for high-temperature resistant cables uses dibasic lead phthalate with good heat resistance. Most foreign formulas are lead-free and cadmium-free to prevent lead and cadmium poisoning. At present, composite lead stabilizers are also widely used in PVC cable materials, with an addition amount of 4~6PHR. Calcium/zinc composite stabilizers are mostly used in environmentally friendly cable materials. Adding antioxidants to the formula can inhibit the thermal oxidative degradation of PVC. Bisphenol A can be used as an antioxidant.

Lubricant

Due to the presence of a large amount of plasticizer, the requirements for internal lubricants are not very high. Lubricants are mainly used to improve the surface brightness of cable materials. Metal soaps, stearic acid and paraffin are often used, and the addition amount is about 1PHR.

Filler

Adding fillers to cable materials can improve electrical insulation performance, heat resistance and reduce costs, but excessive use will cause the formability and performance of the cable material to deteriorate. In order to improve insulation, calcined clay (electrical grade) is selected as a filler in insulation-grade cable materials. Calcium carbonate can be selected as a filler for sheath (layer)-grade cable materials.

PVC insulation grade cable material

Production formula: (parts by weight)

(1)PVC 100 Dibasic lead phosphite 2

DOP 20 Lead stearate 0.8

Chlorinated paraffin 18 Calcium stearate 0.4

M-50 18 Calcium carbonate 4

Tribasic lead sulfate 3 Calcined clay 6

(2) Low cost

PVC 100 DOP 38

Epoxidized soybean oil 3 Chlorinated paraffin 12

Tribasic lead sulfate 5 Dibasic lead stearate 2

Clay 10 Calcium carbonate 10

(3) Electrical properties

PVC 100 Basic lead carbonate 6

DOP 34 Calcium stearate 1

42% Chlorinated paraffin 17 Bisphenol A 0.25

Electrical Grade Clay 10

Related properties: Hardness (Shore) 91; Tensile strength 20MPa; Elongation 430%; Tensile strength retention 105%; Elongation retention 92%; Wire temperature resistance 60℃.

(4)PVC 100 Basic lead carbonate 6

DOP 27.5 Calcium stearate 1

52% Chlorinated paraffin 27.5 Bisphenol A 0.25

Electrical Grade Clay 10

Related properties: Hardness (Shore) 89; Tensile strength 20MPa; Elongation 420%; Tensile strength retention 104%; Elongation retention 100%; Wire temperature resistance 60℃.

(5)PVC 100 Tribasic lead sulfate 6

DIDP 55 Calcium stearate 1

Electrical grade clay 10 Bisphenol A 0.25

Related properties: Hardness (Shore) 83; Tensile strength 17.2MPa; Elongation 390%; Tensile strength retention 104%; Elongation retention 117%; Wire temperature resistance 90℃.

(6)PVC 100 Tribasic lead sulfate 6

DIDP 45 Calcium stearate 1

42% Chlorinated paraffin 15 Bisphenol A 0.25

Electrical Grade Clay 10

Related properties: Hardness (Shore) 83; Tensile strength 16.8MPa; Elongation 310%; Tensile strength retention 100%; Elongation retention 113%; Wire temperature resistance 90℃.

(7)PVC 100 Tribasic lead sulfate 6

DIDP 40 Calcium Stearate 1

52% Chlorinated paraffin 22 Bisphenol A 0.25

Electrical Grade Clay 10

Related properties: Hardness (Shore) 85; Tensile strength 18.3MPa; Elongation 340%; Tensile strength retention 99%; Elongation retention 109%; Wire temperature resistance 90℃.

(8)PVC 100 Calcium stearate 1

Pentaerythritol octanoate 55 Bisphenol A 0.25

Phthalic acid 6

Related properties: Hardness (Shore) 83; Tensile strength 17.7MPa; Elongation 320%; Tensile strength retention 106%; Elongation retention 103%; Wire temperature resistance 105℃.

(9)PVC 100 DOP 22

DIDP 12 Tribasic lead sulfate 3

Chlorinated paraffin 10 Lead stearate 0.5

Barium stearate 1 Bisphenol A 0.3

Calcium carbonate 20 Titanium dioxide appropriate amount

(10) 70°C

PVC 100 DOP 45

Lead sulfate tribasic 4 Lead phosphite dibasic 3

Lead stearate 0.5 Barium stearate 1

Calcium carbonate 10 Bisphenol A 0.5

Titanium dioxide 2 colors appropriate amount

(11) 600V

PVC 100 DOP 40

50% chlorinated paraffin 15 Tribasic lead sulfate 5

Lead stearate dibasic 0.5 Lead stearate 0.5

Calcium carbonate 20 Calcined clay 10

(12) 600V

PVC 100 DOP 50

Tribasic lead sulfate 2 Barium stearate 1

Clay 10

PVC sheath grade cable material

(1)PVC 100 Dibasic lead phosphite 2

DIDP 30 Barium stearate 1

TCP 12 Lead stearate 1

DOP 13 Calcium carbonate 8

Tribasic Lead Sulfate 3

(2) Heat resistance 105℃

PVC 100 Barium stearate 0.6

TOTM 62 Dibasic Lead Phthalate 6

Tribasic lead sulfate 1 Bisphenol A 0.4

Lead stearate 0.6

(3) Heat resistance 70℃

PVC 100 DOP 35

DOS 10 Tribasic Lead Sulfate 4

Dibasic lead phosphite 3 Barium stearate 1

Lead stearate 0.5 Calcium carbonate 15

Titanium dioxide 2 Bisphenol A 0.5

(4) Soft type

PVC 100 DOP 30

DOS 30 Epoxy Ester 6

Barium stearate 3 Cadmium stearate 1.5

Bisphenol A 0.25

(5) Cold resistance

PVC 100 DOP 10

DOS 28 T-50 18

52% Chlorinated Paraffin 8 Tribasic Lead Sulfate 3

Dibasic lead phosphite 4 Dibasic lead stearate 1

Calcium stearate 1 Bisphenol A 0.5

Calcium carbonate 5

(6) Non-migratory type

PVC 100 Polyester plasticizer 66

Tribasic lead sulfate 5 Lead stearate 1

Mineral oil 0.3

(7) Light-resistant type

PVC 100 DOP 22

DOS 20 TCP 7

T-50 5 Tribasic lead sulfate 2

Dibasic lead phosphite 5 Dibasic lead stearate 0.3

Barium stearate 0.7 Bisphenol A 0.1

UV-529 0.1

(8) Wear-resistant type

PVC 100 Dibasic Lead Sulfate 1

Tribasic lead sulfate 5 Trioctyl trimellitate 40

Trimethylolpropane trimethacrylate 5

(cross-linked by electron beam irradiation) wear resistance ≥ 500 cycles

(9) Fatigue resistance

PVC 100 Tribasic lead sulfate 6

DOP 60 Lead Stearate 1

Acid amide 0.5 Calcium carbonate 50

Related performance: Can be bent repeatedly 50,000 to 60,000 times.

(10) Oil resistant type

PVC 100 Chlorinated paraffin 13

741 40 Tribasic lead sulfate 3

DOP 20 Dibasic Lead Sulfate 2

DBP 8 Bisphenol A 0.4

TCP 18 Ba/Cd/Zn composite solution 1

741 is ELVALOY741, which is an ethylene-vinyl acetate-carbon monoxide copolymer product produced by DuPont in the United States.

(11) Transparent type

PVC 100 DOP 25

Barium stearate 1 DBP 15

Calcium stearate 0.8 Stearic acid 0.3

Organotin 8831 2.5 Triphenyl phosphite 0.3

Other special performance cable materials

(1) High-performance PVC cable material

PVC 100 Calcined clay 5

TOTM 40 Lubricant 1

Tribasic Lead Sulfate 5

Related properties: Volume resistivity 8×10 15 Ω•cm; ε=4.2; Dielectric loss tangent 0.85.

(2) Flame retardant, low smoke, heat resistant PVC cable material

PVC 100 Dibasic Lead Sulfate 2

TOTM 40 Lead Stearate 0.8

Tribasic lead sulfate 6 Barium stearate 0.7

Stearic acid 0.3 Antimony trioxide 2

Paraffin 0.5 Zinc borate 8

Antioxidant 7096 0.5 Calcium carbonate 10

Related properties: oxygen index 31.8%; smoke density per unit mass 14.5g; volume resistivity 5.9×10 12 Ω•cm; thermal aging mass loss ≤22.7g/m²; tensile strength ≥20.7MPa after aging at 135℃, 168h.

(3) Low smoke flame retardant PVC cable material

PVC 100 Stabilizer 7

DOP 30 Hydrated zinc borate/Sb 2 O 3 (1:1) 4~6

Chlorinated paraffin 20 Aluminum hydroxide 20~40

TCP 15 Antioxidant 0.5

Related properties: tensile strength 18.7MPa; elongation 330%; volume resistivity 3.7×10 12 Ω•cm; dielectric strength 22.8V/m; oxygen index 32%; maximum smoke density 295Dm.

(4) Low smoke and low halogen flame retardant PVC cable material

PVC 100 DOP 40

DOS 10 Tribasic Lead Sulfate 5

Lead stearate 1 TCP 2

Hydrated zinc borate 6 Aluminum hydroxide 40

Molybdenum trioxide 1.5 Calcium carbonate 90

(5) 120℃ resistant PVC cable material

PVC 100 Dibasic lead phthalate 3

Tribasic lead sulfate 4 Bisphenol A 0.5

Dibasic lead sulfate 4 Antioxidant 1010 0.4

Lead stearate 1 Active calcium carbonate 10

Dibasic Lead Stearate 3 TOTM 30

(6) Chemically cross-linked PVC cable material

PVC 100 TAIC crosslinking agent 2~6

Stabilizer 4.5 DCP 0.5~0.8

Plasticizer 40

(7) Flame-retardant PVC cable material resistant to 105°C

PVC 100 TOTM 33

DTDP 10 Chlorinated paraffin 8

Antimony trioxide 5 Tribasic lead sulfate 4.5

Dibasic lead phosphite 3 Barium stearate 2

Bisphenol A 0.5 Calcium carbonate 3

(8) Semiconductive materials for shielding

PVC 100 DOP 35

Dibasic lead phthalate 5 Calcium stearate 2

Acetylene black 50~80

By adding acetylene black to the PVC formula, the volume resistivity can reach 10 3 Ω•cm, making it a semi-conductive material.

(9) Oil-resistant PVC cable material

PVC 100 Nitrile rubber 40

DOP 30 Tricresyl phosphate 20

Chlorinated paraffin 10 Tribasic lead sulfate 5

Bisphenol A 0.3~0.5 Liquid Ba/Cd/Zn 1

(10) Lead-free and cadmium-free PVC cable materials

PVC 100 DOP 45

Epoxidized soybean oil 5 Ba/Cd/Zn stabilizer 4

Calcined clay 10 High melting point paraffin 0.5

(11) Lead-free, cadmium-free, heat-resistant PVC cable material

PVC 100 DIDP 20

Epoxidized soybean oil 4 octyl tristearate 15

Ba/Cd/Zn stabilizer 5 Calcined clay 10

High melting point paraffin 0.5