01

CCS/CCA/CCAM Wire Copper Electro - Plating Line

Equipment details

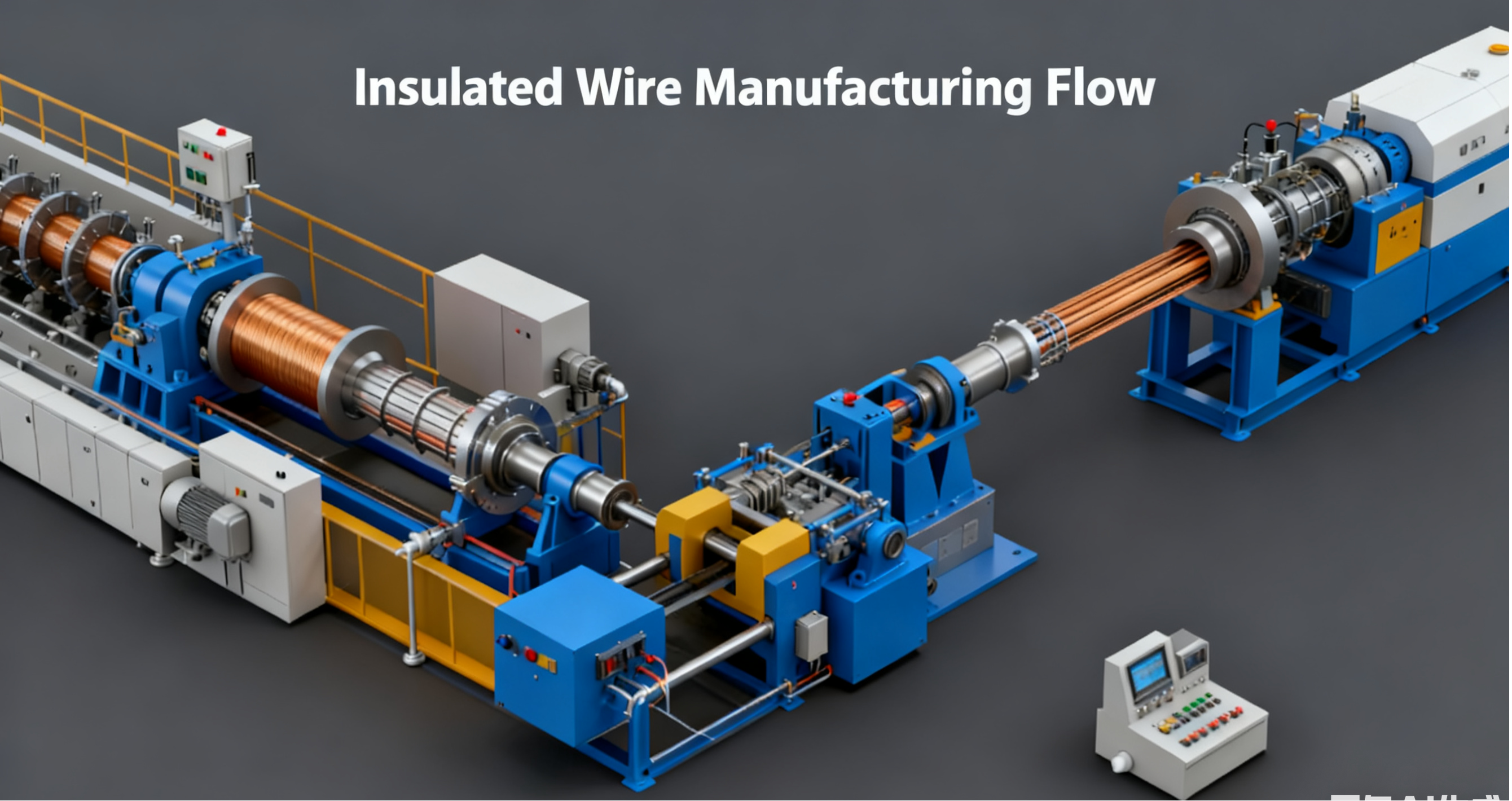

Production Line Overview

This electroplating production line is designed to meet the needs of the Indian market and is optimized for the efficient production of copper clad steel (CCS), copper clad aluminum (CCA), and copper clad aluminum magnesium (CCAM) wires. The production line adopts a modular design, is compatible with a variety of wire specifications, supports high-precision copper plating technology, and meets the needs of India's power, communications, and new energy fields for highly conductive and corrosion-resistant wires.

Core process optimization

Common process flow (CCS/CCA/CCAM)

Paying off → alkali cleaning → electrolytic pickling → water rinsing (3 steps) → pre-plating → water rinsing → main copper plating → water rinsing → hot water washing → drying → pulling → winding up

CCA ( copper clad aluminum wire )

CCAM ( copper clad aluminum magnesium alloy wire )

CCS (copper clad steel wire)

Degreasing : remove the oil on the surface of product to ensure the binding force of the coating.

Pickling : remove the oxide from the surface of the product.

Water rinsing : clean the product thoroughly after the tank to avoid mutual contamination of the tank.

Chemical zinc plating 1 : pre-treatment before electroplating, forming a dense zinc alloy layer.

Dezinc : remove zinc layer and impurities from substrate surface.

Chemical zinc plating 2 : forming a dense zinc alloy layer and improving the binding force of subsequent electroplating.

Pre-copper plating : as a pre-coating, to ensure the subsequent coating and base binding force.

Acid copper plating : thickened copper coating to increase conductivity.

Key optimization points:

§Water

saving design: The three-stage countercurrent water washing system reduces water consumption by 30%, meeting India's water-saving and environmental protection requirements.

§Intelligent

circulation control: automatic plating solution pump circulation + scraper design reduces solution loss and increases plating solution utilization by 20%.

§Dual

stage pre-plating technology: For aluminum/aluminum-magnesium substrates, add chemical zinc plating (1&2 stages) + zinc stripping process to enhance the bonding strength of the copper layer (>15% improvement).

Differentiated process adjustment

CCS, cathode/anode double stage degreasing, direct pre-copper plating after pickling, high-strength steel core transmission conductor.

CCA, chemical zinc plating (twice) + zinc stripping, pre-copper plating to enhance bonding strength, lightweight communication cable.

CCAM, magnesium alloy pretreatment + anti-oxidation coating, post-stage hot water washing temperature control, new energy battery connecting wir.

Equipment parameters and technology upgrades

Core parameters (adapting to Indian needs)

§Wire diameter range: 0.6mm–4.0mm (extended to common Indian specifications φ1.0–3.0mm).

§Production speed: 10–50m/min (supports low-speed and high-precision mode of 5m/min to meet small batch customization).

§Copper plating amount: 30–400g/kg (adjustable, default 120g/kg, in line with Indian IS 398 standard).

§Conductivity : ≥20% (copper layer thickness 0.02–0.05mm adjustable).

§ Daily output:

φ2.0mm wire: 19T/day (32 wire counts);

φ1.0mm wire: 4.2T/day.

Annual production capacity: 6840T (calculated based on 360 days, supporting three-shift production).

§ Comprehensive calculation of production capacity (120-30kg/t):

|

Diameter |

Number of online |

speed |

Pre-plating current |

Main plating current |

24 - hour output |

| 3.0mm | 36 | 6.5m / min | 578/620 | 6120/7548 | 4.8t |

| 2.5mm | 36 | 7m/min | 552/568 | 5760/6840 | 3.5t |

| 2.05mm | 36 | 7m/min | 400/542 | 5368/6120 | 3.0t |

| 1.2mm | 36 | 7m/min | 150/200 | 3600/3960 | 1.5t |

Upgrade of key equipment

§Power system:

Pre-plating: 2000A/6V high frequency rectifier (1 unit), supports constant current/constant voltage mode.

Main plating: 6000A/9V high frequency rectifier (2 sets), plating uniformity ±5%.

§ Plating tank design:

Material: 15mm PP plate (acid and alkali resistant) + stainless steel frame (SUS304).

Temperature control: alkali washing tank (65℃±2℃), zinc stripping tank (25–30℃), PID precise control.

The plating tanks are all made of white or gray 15mm PP plates, the heating part of the alkali washing and hot water washing is made of white 15mm PP plates, and the plating tank frame is made

of carbon steel or stainless steel .

No.1 alkali tank: size: 3500*1100*120, low-level tank: 2800*800*500, heating 65 degrees, controlled pump circulation, and a scraper plate is used after the overflow plate to reduce the loss of liquid (2-stage alkali tank).

No.2 pickling tank is 1 section: 2000*1100*120, low-level tank: 1500*800*500 pump circulation, and a scraper plate is used after the overflow plate to reduce the loss of liquid.

No.3 zinc tank: 3300*1100*120, a scraper plate is used after the overflow plate, and the low-level tank is 2500*800*500.

No.4 zinc stripping tank: 2000*1100*120, low-level tank: 2000*800*500 pump circulation, use a scraper after the overflow plate to reduce liquid loss.

No.5 zinc tank: 3300*1100*120, use a scraper after the overflow plate, low-level tank 2500*800*500.

No.6 pre-plating tank: 8000*1100*120 pump circulation, use a scraper after the overflow plate to reduce liquid loss , low-level tank 6000*800*500.

No.7 main plating tank: 8000*1100*120 pump circulation, use a scraper after the overflow plate to reduce liquid loss , low-level tank 6000*800*500 (7 sections of main plating 42 meters)

No.8 cleaning tank 6 sections: 1200*1100*120, use high-pressure flushing surface flushing.

No.9 curing tank: 1200*1100*120. Use a scraper to reduce the loss of liquid behind the overflow plate.

No.10 Flat drying furnace: size: 2 meters long * 0.9 meters high * 1.3 meters wide [can be customized according to customer requirements] .

No.11 Wire-reeling part: The wire reel is equipped with a torque converter motor and has a wire reel size of 500mm .

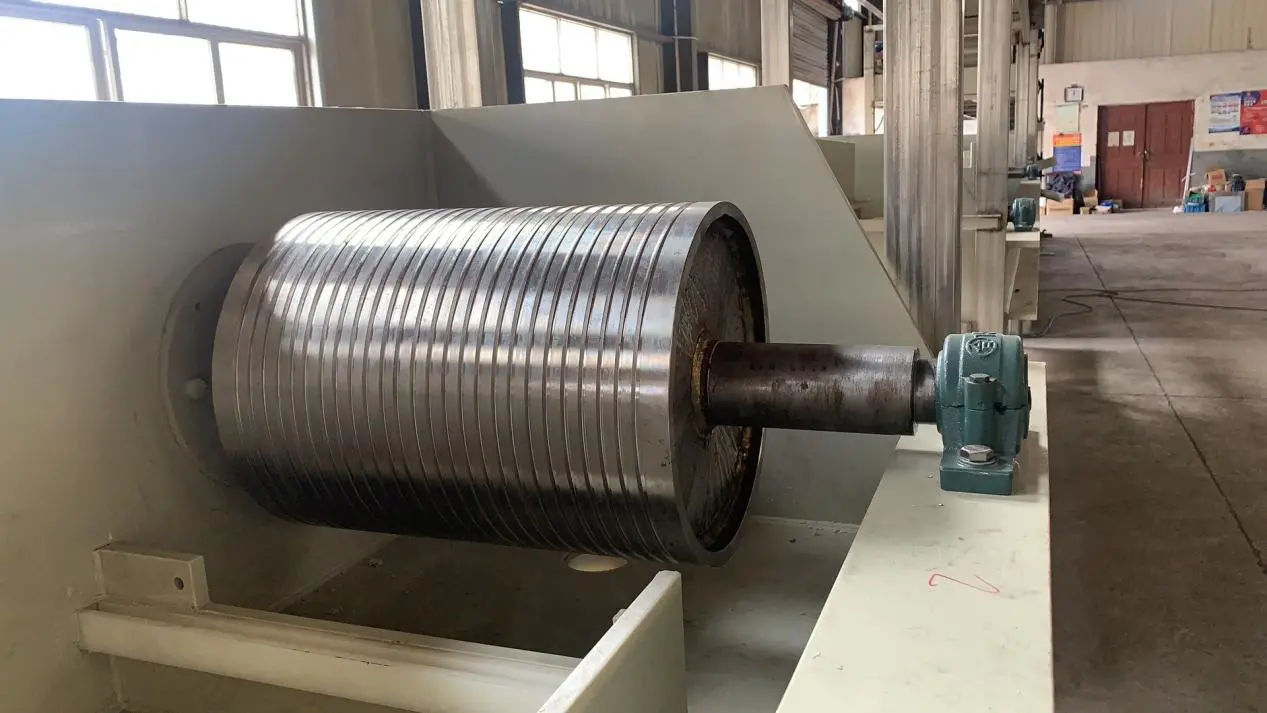

§Shafted wire take-up machine:

The wire take-up is arranged on the left and right sides, with 18 wire take-up ends on each side;

1. Wire take-up method: screw rod wire arrangement;

2. Tension adjustment: inverter;

3. Wire take-up limit: 70kg;

4. Wire guide wheel ¢12mm: 72 wire inputs, 72 wire take-up ends, and 72 turning ends.

§Drying system:

Tubular drying furnace (2m×1.3m×0.9m), supports 40–50℃ hot water washing + cold air drying, anti-oxidation.

① Softening furnace length 2.m;

② Softening furnace tube SUS304 steel tube, a total of 36 tubes;

③ Tubular softening furnace electric heating capacity 12kw;

④ Softening temperature control: temperature gauge 400℃, ON, OFF output control;

⑤ Anti-oxidation device: A water tray is set at the outlet of the softening furnace tube to isolate the oxidation in the softening tube;

⑥ Heat insulation and insulation: Special insulation cotton covers the furnace body, with excellent heat insulation and insulation effects;

⑦ Drying furnace heating: Tubular heating design, easy to replace and maintain;

⑧ Softening temperature measurement point: KTPE1 position.

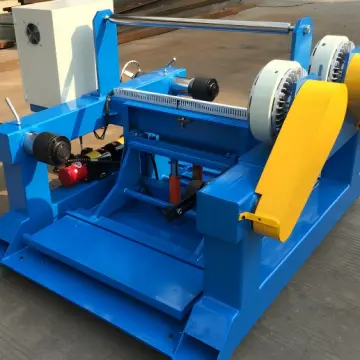

§Single-wheel take-up machine

①Appearance : single-wheel take-up wheel, side transmission and support machine base;

②Take -up wheel: surface spray-welded aluminum oxide, light wheel 96mm;

③Power : 1HP induction motor with inverter control to adjust the operating line speed;

④Production line speed: 0 - 8m/min;

⑤Wire passing wheel: 36 each for inlet and outlet;

§Electrical control box①Main

①power switch;

②Softening furnace temperature and electric heating control;

③Line speed frequency conversion control and line speed display;

④36 -head coiler frequency conversion control;

⑤Reel inverter speed control, 36-head coiling pay-off rack line spacing 1 meter;

⑥Total machine power: 120kw; Equipment tank height is 0.84 meters , pay-off and take-up parts are 18 meters each, take-up is 12 meters, and the total length of the entire production line is 120 meters;

Equipment list

① Plastic plate gray PP15mm

② Water pump , pipe valve parts

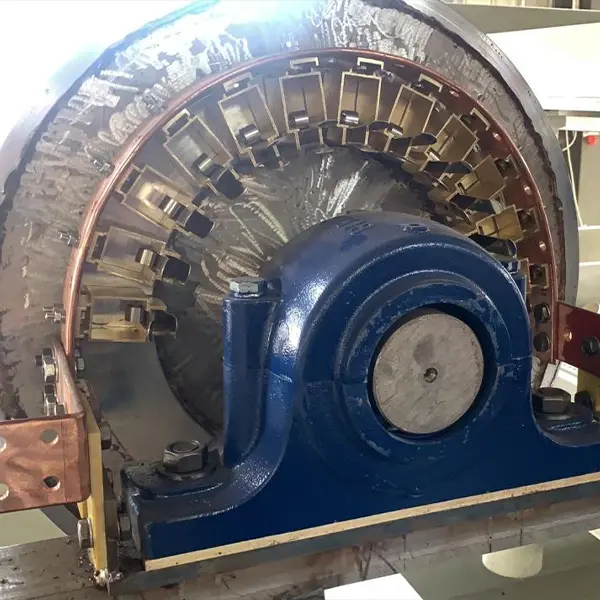

③ Pre-plating main plating roller YD500-32H

④ Titanium plate, 60mm×4mm×1940mm 50mm×50mm×5mm2160

⑤ Copper bar

pre-plating: 50mm×5mm

60mm×8mm

Main plating: 100mm×8mm

60mm×8mm

⑥ Rectifier:2000A/6V 7 units 1500A/6V 1 unit

Environmental protection and energy saving

Wastewater treatment module:

integrated neutralization sedimentation + membrane filtration system, wastewater reuse rate ≥ 80%.

Energy consumption:

main motor 5.5kW + inverter power supply 4kW, comprehensive energy consumption reduced by 15%.

Integration of technical advantages

1. Patented plating solution formula: exclusive zinc alloy pre-plating technology, reducing porosity and improving salt spray resistance (>1000 hours).

2. Intelligent control system: PLC+HMI human-machine interface, real-time monitoring of line speed, current, temperature, and support for fault self-diagnosis.

3. Quick line-changing design: modular plating tank + adjustable guide wheel spacing (33mm±5mm), line-changing time <2 hours.

Adaptation plan for the Indian market

1. Cost optimization:

Optional economical plating tank (carbon steel frame) or high-end stainless steel model, with a payback period of <3 years.

2. Compliance Certification:

Comply with India's BIS certification, CE standards and RoHS environmental protection requirements.

Equipment List

Main plating tank, 8000×1100×120mm (PP plate), 2 units.

High frequency rectifier, 6000A/9V, 2 units.

Tubular drying furnace, 2m×1.3m×0.9m (304 stainless steel), 1 set.

Intelligent control system, PLC+7-inch touch screen, 1 set.

After-sales service commitment

Warranty period: 1 year for the whole machine, 3 years for core components (rectifier, pump).

Upgrade service: free process upgrade package (plating solution formula, control software) within 5 years.

Other machinery or services:

Copper drawing machine, aluminum drawing machine, frame stranding machine , tube stranding machine, cage stranding machine, stranding machine, multi-head wire drawing machine (with annealing machine), copper wire drawing machine, ultra-fine wire drawing machine, copper-clad aluminum wire drawing machine, copper-clad steel wire drawing machine , cutting wire drawing machine, diamond wire drawing machine, bonded gold wire drawing machine, stainless steel wire drawing machine, brass wire drawing machine , copper wire stranding machine, annealing machine, wire drawing machine with continuous annealing machine, copper plating machine, aluminum plating machine , pulley wire drawing machine, straight-feed wire drawing machine and other mechanical equipment.

description2