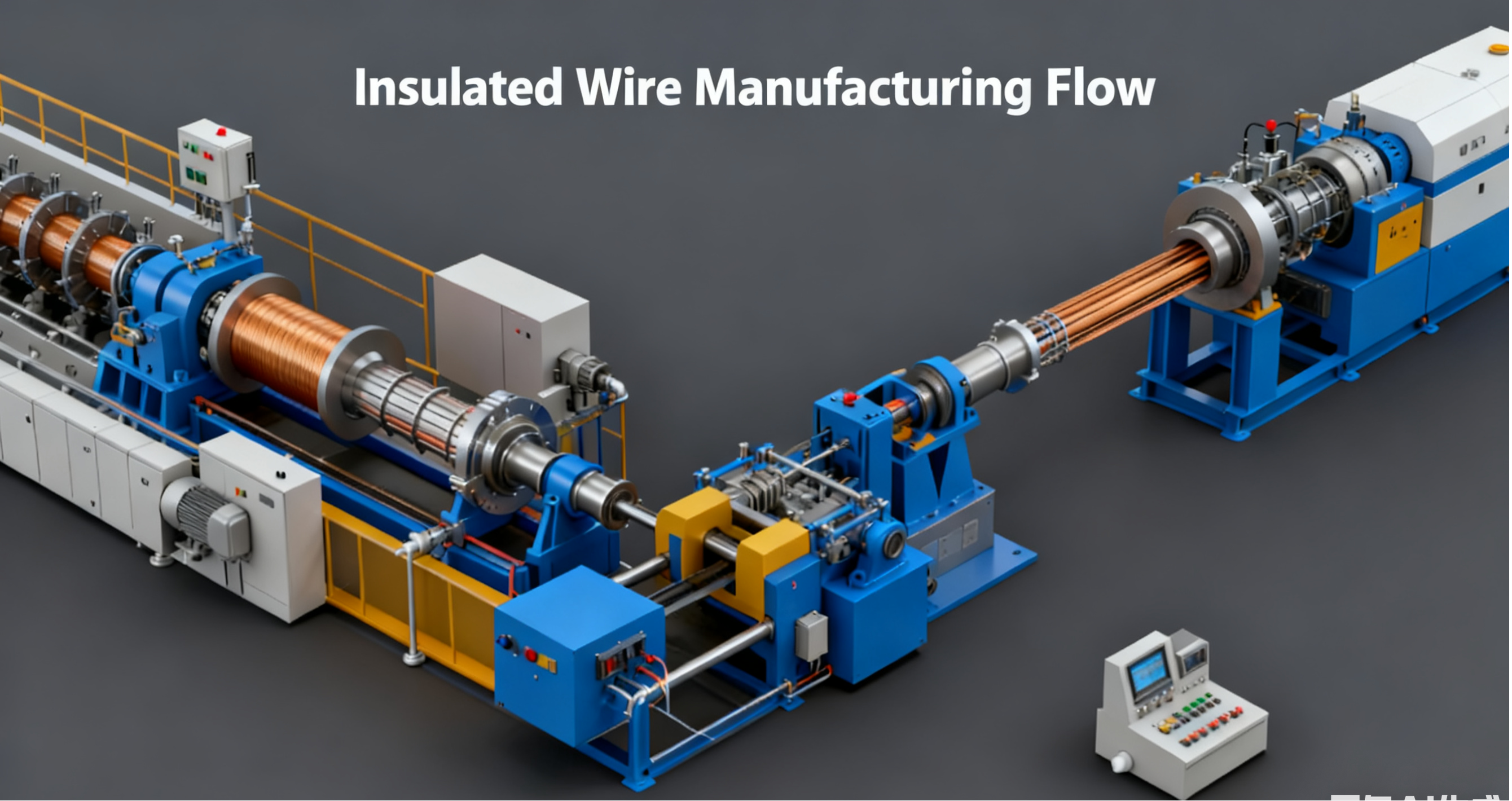

Technical Specification for Φ80+50 Double-Layer Insulation Co-Extrusion Production Line for Photovoltaic Cables

Equipment Description

Ø70+90 Double-Layer Insulation Tandem Extrusion Production Line for Photovoltaic Cables

Technical Parameters

1. Equipment Purpose

This equipment is suitable for producing solar photovoltaic cables, low-smoke halogen-free cables, irradiated cables, and XL-PE cross-linked polyethylene cables; it is also applicable for conventional plastic extrusion such as PVC and PE.

Second-hand PN500/1+6+12--1600 cage type stranding machine

Technical parameters:

▶ Wire drum specifications: PN500 type (Φ500×L375×d56)

▶ Number of strands: 6+12 structure (1+6+12 cage stranding machine)

▶ Stranding pitch range: 160~320mm

▶ Single wire diameter range: 1.5~4.0mm

▶ Maximum stranding cross section: 10~120mm²

▶ Speed range: 5~50 rpm (PLC control model can achieve higher accuracy)

▶ Motor configuration: Main motor 5.5 +7.5kw, lifting motor 1.5kw

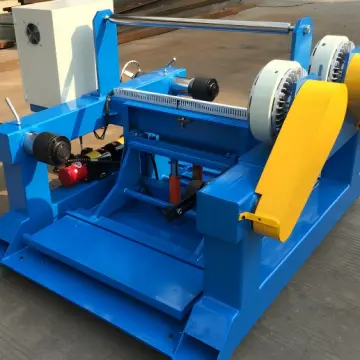

Used Copper Coarse Wire Drawing Machine DL450/9D, Feed Rod Diameter 8mm and Outlet Diameter 3mm

The professional term for drawing machine is also called thick wire drawing machine, which is used for the drawing and annealing of copper wire, aluminum wire, brass wire, and copper-magnesium alloy wire for high-speed rail contact wire.