01

BAOC-20 MDS+WS630 Aluminum Alloy Wire Gear iddle Drawing Machine

TECHNICAL PARAMETER

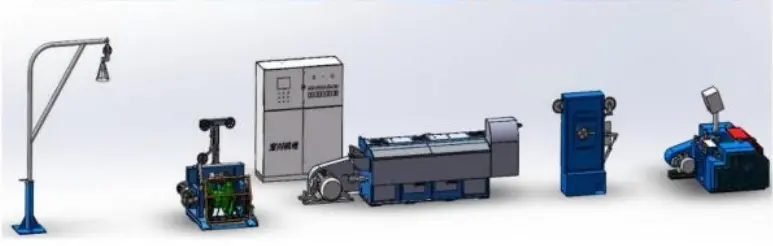

| 1 | Pay-off stand (frame pay-off) | 1 piece/unit |

| 2 | 630 active pay-off stand | 1 piece/unit |

| 3 | BAOC250-20 wire drawing machine | 1 set/unit |

| 4 | Electrical control system | 1 set/unit |

| 5 | Tension controller | 1 set/unit |

| 6 | BAOC-WS630 reel-type take-up machine | 1 set/unit |

| 7 | User manual | 1 set/unit |

| 8 | Random items | 1 set/unit |

| 9 | Equipment cabinet (for serving purpose) | 1 |

connection wire II. Main technical parameters

| Applicable Raw Materials | Aluminum alloy wire (tensile strength < 420MPA) |

| Wire Entry Range | ÿ1.8 – ÿ2.6mm |

| Wire Range | ÿ0.30 – ÿ1.2mm |

| Wire Speed | 1200MPM |

| Max. Eye Modules | 20 (prepared by buyer) |

| Eye Mold Outer Diameter | ÿ25mm X 10mm thick |

| Mechanical Reduction Rate | 15% for 1st-19th, 20% for 20th piece |

| Main Engine Motor | 37KW-AC, variable speed by inverter |

| Winding Motor | 11KW-AC, independent inverter |

| Coil Capacity | 250 – 500KG/MAX |

| Winding Outer Diameter | ÿ630mm/MAX (inner hole ≥ 125mm) |

| Wire Drawing Wheel | Spray-welded tungsten carbide, 5-layer integrated |

| Wire Drawing Lubrication | Full immersion |

| Wire Arrangement Method | 90W reversible motor, toothed synchronous belt drive |

| Braking System | Pneumatic disc brake |

Power supply: provide the required total power

| Three-phase Voltage | AC 3×380V (±10%) |

| Single-phase Voltage | AC 220V (±10%) |

| Power Frequency | 50 Hz (±2%) |

Compressed air

| Work Pressure | 0.6ÿ0.7 Mpa |

| Fluctuation Value | +0.02 Mpa |

| Dew Point | -25 ÿ |

| Flow Rate | 200 L/min |

Equipment introduction of the main components

| Frame-type Pay-off Machine | |

| - Pay-off Specifications | Rotary double-station barrel type |

| - Anti-jumping Device | Installed between two top steering wheels |

| - Pay-off Frame Height | 3.2 meters |

| 630 Active Pay-off Machine | |

| - Form | Integrated pay-off + swing rod wire storage |

| - Applicable Wire Reel | ÿ630mm wire reel |

| - Adaptable Line Speed | Max 200-800m/min |

| - Adaptable Wire Diameter | Max ÿ3.5mm |

| - Power | 4KW AC motor + inverter control |

| - Top Shaft Method | Pneumatic clamping and loosening |

| - Shutdown on Wire Break | Equipped with brake device |

| - Safety | Mobile protective cover installed |

| - Wire Storage Length | 3-5 meters |

| - Wire Storage Wheel | 220mm outer diameter, porcelain-sprayed aluminum guide wheel (2 up, 3 down) |

| - Displacement Signal | Non-contact displacement sensor |

| - Speed Synchronization | Speed synchronization signal input point for host synchronization |

| Host Part | (No specific details provided) |

Overall structure

| Material | Q235 |

| Structure | |

| - Construction | Welded from steel plates, annealed, and bored by precision boring machine |

| - Characteristics | No deformation, high precision |

| Power Transmission | |

| - Gear Drive | Precision cast, high-frequency quenched, and high-precision ground gears |

| - Transmission Efficiency | High |

| - Main Motor Drive | High tension V-belt |

| - Final Drawing Wheel | Toothed synchronous belt drive |

| Transmission Shaft | |

| - Material | S45C (#45 steel) |

| - Precision | Shaft center tempered to HRC25-27 to eliminate stress and improve rigidity; mating parts ground to maintain concentricity and straightness |

Wire drawing WHEEL

| Wire Drawing Wheel | Material: S45C surface spray-welded tungsten carbide Type: Five-layer integrated type (four, interchangeable), Final take-up wheel single-layer (one) Fixing method: Nut-tight type |

| Operating Table | Consists of a meter, a wire speed meter, a button switch, an indicator light, an adjustment switch, an alarm light, etc. Forms an electrical control system with the electrical control cabinet for settings like Automatic production shutdown, emergency shutdown, fault indication |

| Electrical Control System | Power system of the medium pull: Composed of the main inverter (37KW), the drive traction motor, and the take-up motor is independently equipped with an inverter Control system of the high-speed large medium pull: Composed of an inverter, logic control, and an operation panel. Dual frequency conversion control, potentiometer gives wire extension speed signal to the main inverter to control host speed. Main inverter analog outputs 0 - 10V, and the feedback signal to the wire take-up inverter and tension potentiometer (tension swing arm) forms PID operation internally to control the wire take-up speed |

| BAOC - 180 Tension Frame | Type: Pneumatic swing arm type Accuracy: 1 - 10KG, with automatic pressure regulating valve to adjust the tension Use air pressure: 4 ~ 6KG/CM2 (air source provided by the customer) Wire guide wheel: Aluminum guide wheel with ceramic spraying on the surface Displacement detection: Precision resistor 1Kÿ Wire break detection: Micro switch method |

| BAOC - WS630 Shaftless Wire Take-up Machine | N/A |

The WS630 is a high-speed reel-type wire take-up machine. Its control panel is furnished with an emergency stop switch, and the protective door is equipped with a protection switch. It has the capability to be connected to the electrical control system of other equipment, thereby realizing online protection. The take-up machine offers the option of either DC or AC frequency conversion control. The wire arrangement device is powered by an independent motor, and the arrangement spacing can be adjusted through electronic speed regulation. The arrangement position is regulated by a travel switch, and the user can make adjustments according to the width of the take-up reel via a lead screw. The take-up reel used is prepared by the user, and its size is designed and manufactured in accordance with the reel drawing mutually confirmed by both parties.

Specifically, it has the following characteristics:

1. Type: Shaftless thimble type, with a maximum reel outer diameter of MAX630mm. After any alteration in the reel size, the electrical control automatically adapts to the same.

2. Horsepower: AC11 AC motor, driven by an AC11KW inverter.

3. Maximum copper load: 500KG/MAX.

4. Spool: Spool size ranging from ÿ500mm to ÿ630mm (with an inner hole greater than or equal to 125mm).

5. Brake: Pneumatic disc brake.

6. Transmission: Transmission V-belt.

7. Cable arrangement: Servo motor + ball screw. The cable width is adjustable by the motor.

8. Upper and lower axis mode: Pneumatic upper and lower plates.

9. Safety cover: The take-up spool is completely enclosed and features an inspection window. The transmission part is semi-enclosed.

IV. BAOC20MDS+WS630 Copper Wire Drawing Machine (List of Main Components)

description2

| 1 | Wire drawing inverter | MD520 AC inverter | 1 | China |

| 2 | Wire taking-up inverter | MD520 AC inverter | 1 | China |

| 4 | Main motor | 37KW AC380V | 1 | Wuxi, China |

| 5 | Wire taking-up motor | 11KW AC380V | 1 | Wuxi, China |

| 6 | PLC + touch | - | 1 set | Shanghai |

| 7 | Precision resistor | WDD35 - 4 | 1 | Japan |

| 8 | Bearing pulley housing | - | 1 set | - |

| 9 | - | - | - | - |

| 10 | - | 20MD | 1 set | - |

| 11 | Low voltage electrical appliances | - | 1 Set | French Schneider |

| 12 | Wire guide wheel | - | 1 Set | - |

| 13 | Active line frequency converter | MD520 AC frequency converter | 1 set | China |

Equipment-Related Auxiliary Items and Requirements

| 1 | Used for civil engineering of equipment and external pipeline engineering. |

| 2 | Lubricating oil, hydraulic oil and wire drawing emulsion used for equipment lubrication and wire drawing. |

| 3 | Wire drawing emulsion pool for wire drawing (recommended 10m3). |

| 4 | Cooling water pool and circulation system. |

| 5 | Copper rods and wire reels used for test runs. |

| 6 | A complete set of wire drawing dies for wire drawing test of equipment. |

| 7 | Connector machine for connecting copper rods and copper wire ends. |

| 8 | Air source above 0.6Mpa for normal operation of the equipment. |

| BAOC-20MD Aluminum Alloy Wire Gear Middle Pull Machine | Incoming line: 1.8 - 2.6mm, Outgoing line: 0.3 - 1.2mm, line speed: 20m/s | 1 set | 256500.00 | 256500.00 |

| Itemized Quotation | - | - | - | - |

| 630 Active Pay-off Stand | - | 1 | 22000 | 22000 |

| BAOC-250-20D Wire Drawing Machine | - | 1 | 120000 | 120000 |

| 180 Tension controller | - | 1 | 6000 | 6000 |

| WS630 Single Reel Take-up Machine | - | 1 | 56000 | 56000 |

| Electrical control system | - | 1 | 38000 | 38000 |

| ZJ430 Heading Machine (Shanghai Shenchen) | - | 1 | 6500 | 6500 |

| Connection lines between electrical cabinet equipment | - | 1 | 2000 | 2000 |

| Freight | - | 1 | 6000 | 6000 |

| Total: | - | - | - | 256500.00 |

1. The above quotation includes: equipment price, installation and commissioning fee, spare parts fee, technical service fee and transportation fee during the warranty period.

2. Payment method: 30% upon signing the contract, advance payment until the contract takes effect; 60% upon delivery, payment within 3 days after receipt of payment Delivery; 10% within 12 months after acceptance

3. Delivery time: 80 working days after the contract takes effect.

4. Warranty period: One year for electronic control (including two years for inverter), one year for machinery, and lifetime maintenance.