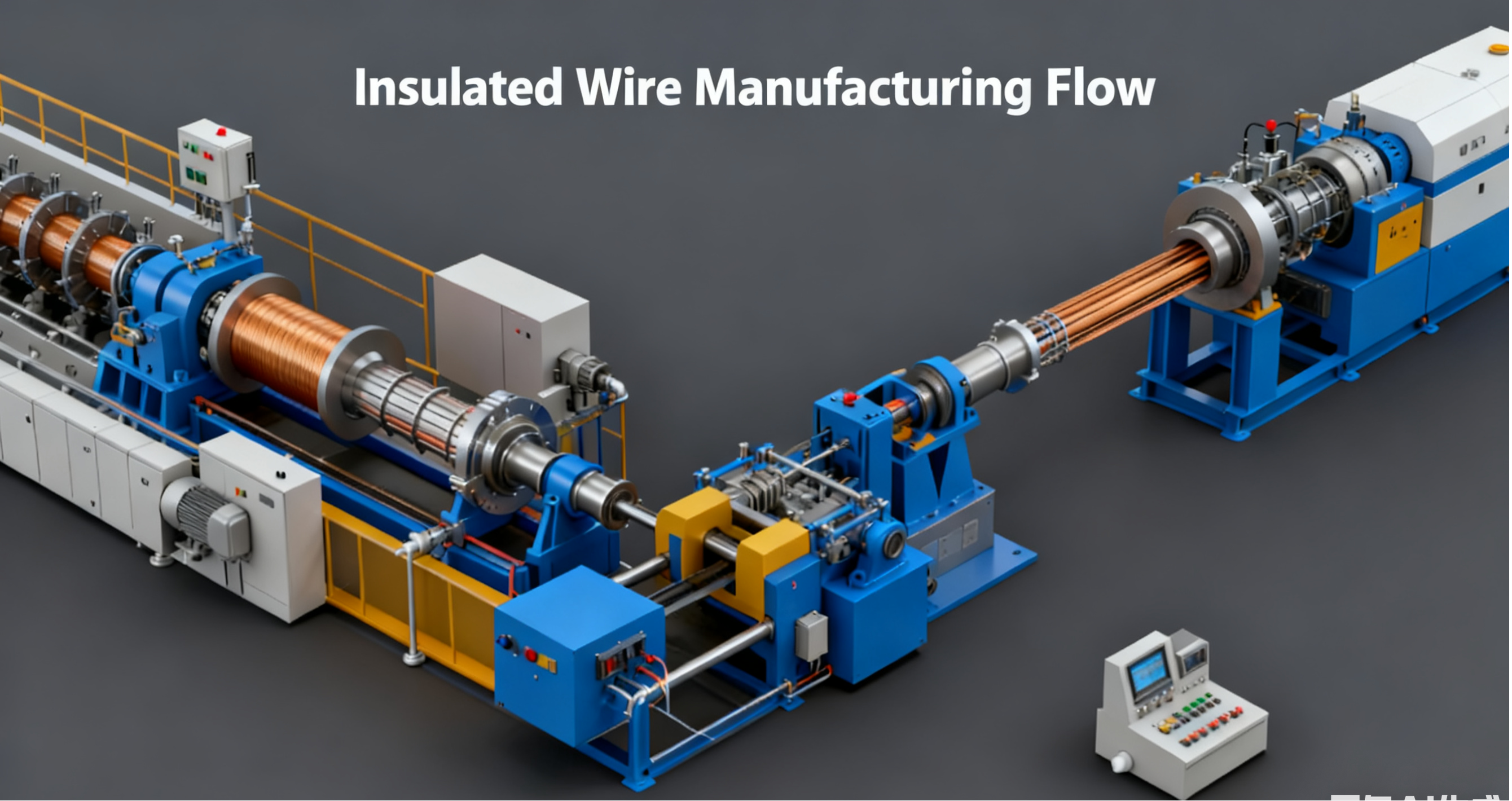

0102

Annual output of 5,000 tons of oxygen-free copper rods, used upward continuous casting

description2

Wire take-up device

The annual production of 5,000 tons of oxygen-free copper rods through the upward continuous casting method marks a major advancement in the manufacturing of high-purity copper products. Oxygen-free copper has excellent electrical and thermal conductivity and is essential in a variety of applications such as electronics, telecommunications and high-performance electrical components.

The upward continuous casting process is a modern technology that allows for the efficient production of copper rods with minimal impurities. The method involves melting the copper and then continuously casting it into a mold where it solidifies as it is pulled upward. The process not only improves the quality of the copper by reducing oxidation, but also improves the mechanical properties of the final product.

With an annual production capacity of 5,000 tons, the manufacturer is able to meet the growing demand for oxygen-free copper rods across various industries. The high purity of these copper rods ensures their optimal performance in applications such as high-frequency transformers, connectors and other critical components that require reliable conductivity.

In addition, the upward continuous casting process is environmentally friendly as it minimizes waste and energy consumption compared to traditional casting methods. As the industry continues to develop and demands for higher quality materials continue to increase, the production of oxygen-free copper rods will play a key role in supporting technological advancement and sustainable practices.