01

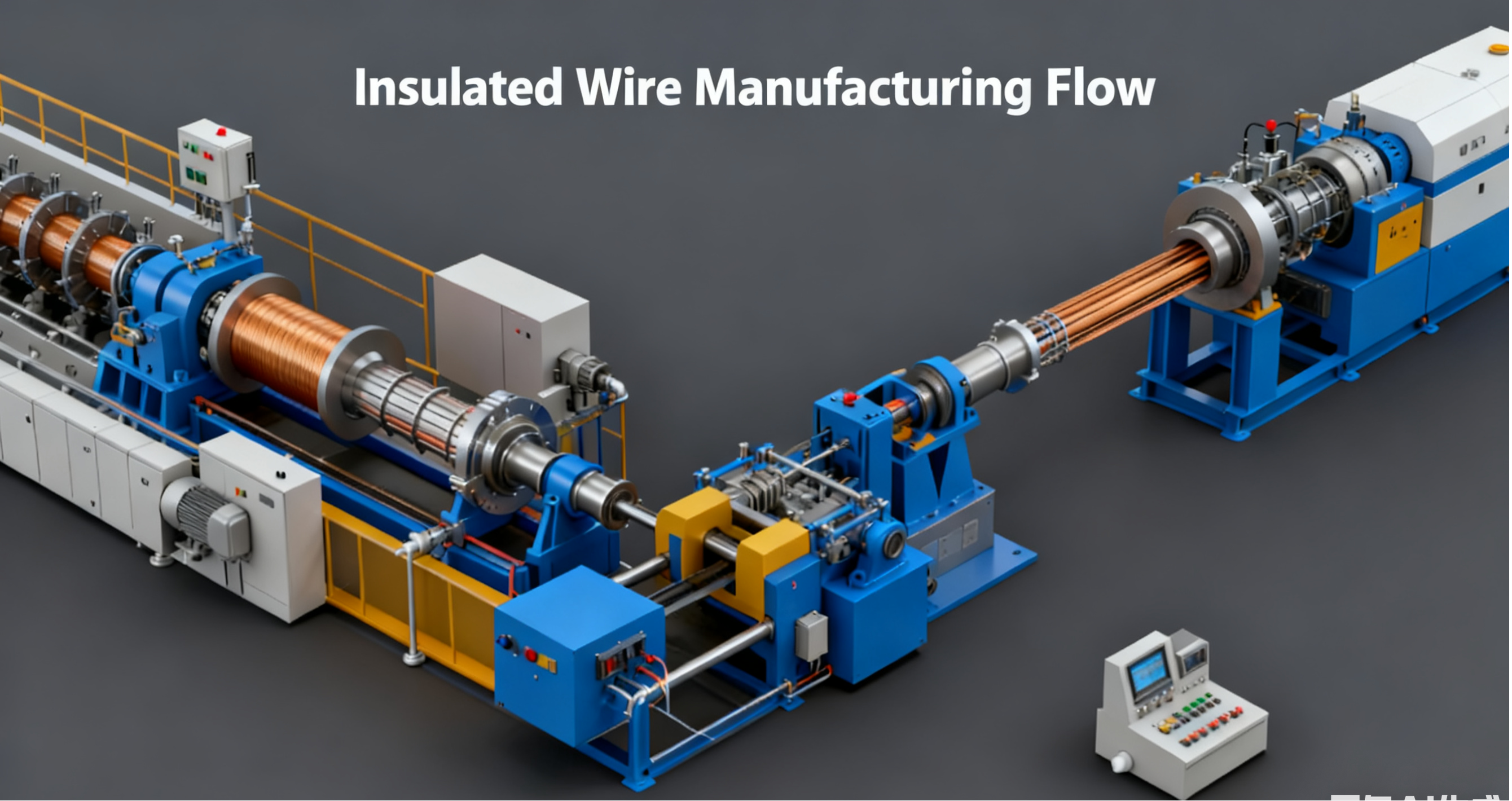

Accelerator irradiation wire and cable product production equipment

1. EQUIPMENT USE

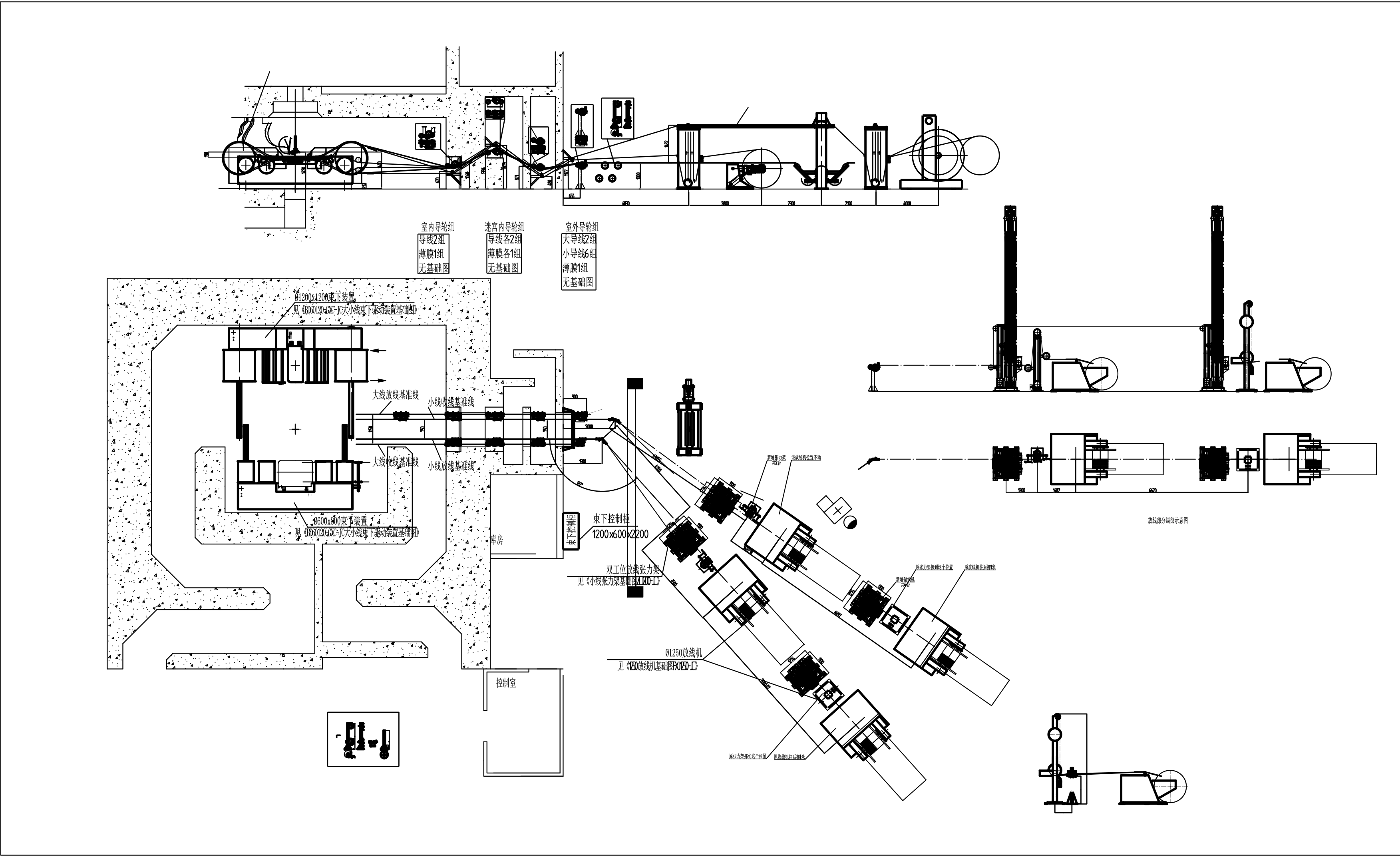

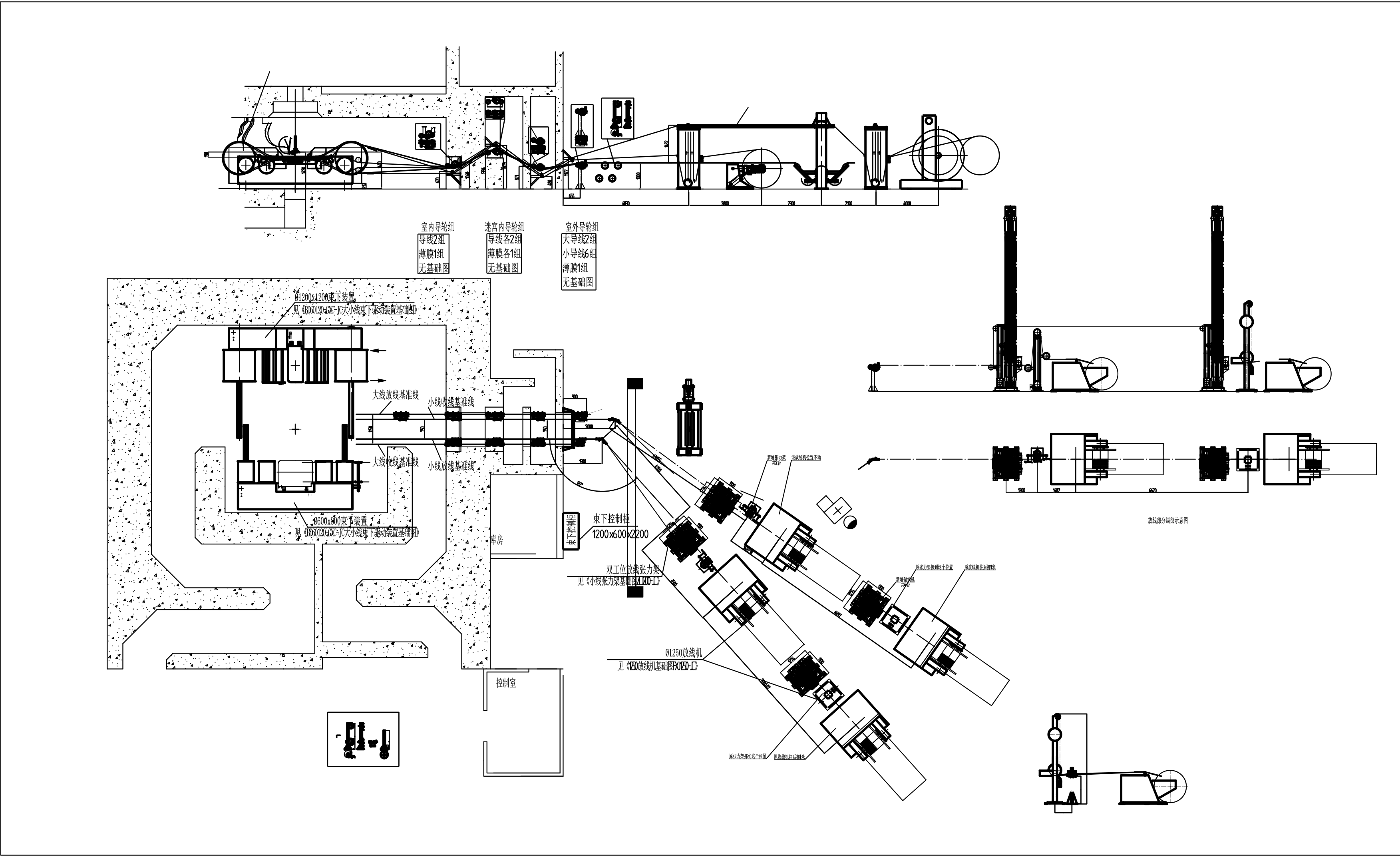

This production line auxiliary equipment can realize two-in-two-outlet and two-outlet of soft and hard wire and cable products with an outer diameter of less than 6mm. Non-stop production, the maximum production speed of a single machine can reach 280m/min, and the maximum production speed of the production line can reach 560m/min production speed, fully improve the beam utilization rate of 2.5mev electron accelerator, and improve the production efficiency of small lines.

2. Production line process

Irradiation production process of soft and hard wires and cables with outer diameter below 6mm:

Pay-off machineÿpay-off wheel group dancing wheelÿbeam traction systemÿtake-up wheel group dancing wheelÿcable arrangement deviceÿ Wire take-up machine;

3. List of auxiliary equipment

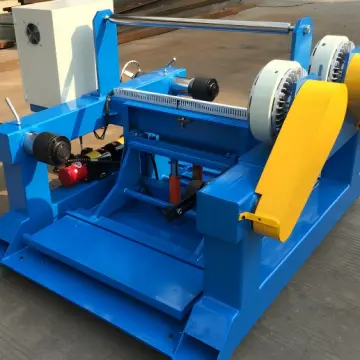

(1).N800 frog type pay-off machine------------------------------2 sets

(2). Pay-off wheel set (diameter 200) dancing wheel ------------------- 2 sets

(3).Large capacity vertical wire storage machine ------------------------------- 4 units

(4).Reel-type (diameter 200) dancing wheel ------------------- 2 sets

(5).PN800 frog type wire take-up machine---------------------------2 sets

4.Equipment structure description and technical parameters

| PN800 Frog-Type Take-Up and Pay-Off Machine | - Structure: Frog-type rectangular tube frame, including frame, pay-off machine, electric opening and closing mechanism, electric lifting mechanism. - Function: Active pay-off and take-up of cables. - Protection: Equipped with over-lifting and over-clamping protection devices. - Pay-Off Motor: 4kW inverter driven by Danfoss inverter. - Applicable Cable Drum: PN500 - PN800 mm. - Lifting Motor Power: 1.1KW. - Opening and Closing Motor Power: 0.18kW. - Cable Motor Power: 0.25 kW inverter driven by Danfoss inverter. - Maximum Speed: 280m/min. - Maximum Disc Weight: 2 tons. |

| Pay-Off Wheel Set (Diameter 200mm, 7+6) Dancing Wheel | - Wheel Diameter: 200mm, with 7 upper and 6 lower wheels. - Line Storage: Over 15 meters. - Tension Adjustment: By counterweight, can add positive or reverse tension. - Applicable Cable Outer Diameter: Maximum 5mm. - Tension: Minimum 1N. - Wheel Material: ABS engineering plastic. |

5. Large capacity vertical wire storage machine

This machine is mainly used in the cable production process. When the cable is almost finished, a part of the wire can be stored in advance.

In the wire storage rack, so as to ensure that the production line does not stop during the reel change process.

The equipment consists of two rows of superimposed wheel groups, with the cables crossing in an S-shape from top to bottom.

The wire storage is realized by increasing the distance between the two superimposed wheel sets. The motor drives the magnetic powder brake to provide wire storage and release.

The equipment adopts a double column structure with front and rear supports, linear bearing guide rails on both sides, and superimposed wheel sets.

Guided by rails on both sides, it runs very smoothly.

The device can be embedded in the production line as an independent functional unit. After installation, it only needs to be connected to the power supply.

When the cable needs to be stored, just press the cable storage button and the device will automatically run to store the cable.

After the cable is fully stored, the equipment is equipped with a tension controller (loop stacking wheel set) at the equipment outlet. The equipment will automatically follow the production line speed to release the stored cables until all the cables are released.

If the cable length is not enough to fill the cable storage machine, the cable storage process can be terminated at any time.

Does not affect the continuous operation of the production line.

There are four wire storage machines in total, two of which are used for paying out wire and two for taking up wire.

| Wire Storage Capacity | Not less than 400m |

| Applicable Wire Diameter | 2.5 - 6mm |

| Production Line Speed | 300 - 400m/min |

| Wire Storage Speed | 100m/min |

| Access Line Height | 1000mm |

| Diameter of Wire Wheel | ±200mm |

| Stacked Wheel Distribution | 20 + 20 wheels |

| Maximum Track Travel | 6m |

| Wire Storage Motor Power | 3kw |

| Tension Control Method | 2.2kw motor + 400N.m magnetic powder brake |

| Dimensions | 1258 (length) × 1276 (width) × 7105 (height) mm |

1. Reel assembly type (diameter 200mm, 7+6) dancing wheel The wheel set uses a 200mm diameter disc wheel, consisting of 7 upper and 6 lower wheels, and also has a certain line storage function (over 15 meters); use counterweight to adjust tension, and can add positive or reverse tension; applicable cable outer diameter Maximum 5mm;

Tension: minimum 1N, wheel material is ABS engineering plastic;

2. Equipment price: 960,000 yuan

3. Delivery time: 100 days