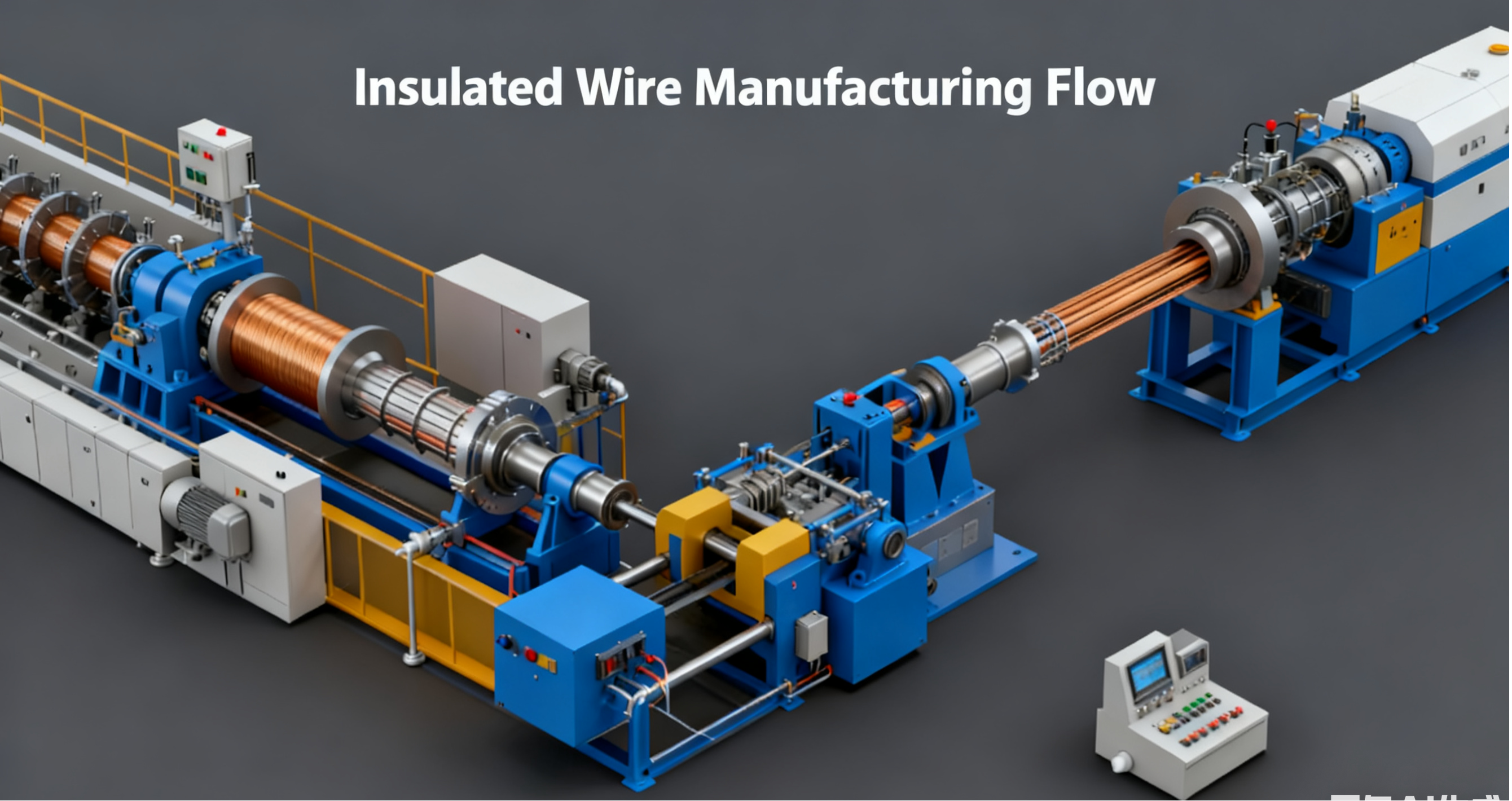

Ø70+90 Double-Layer Insulation Tandem Extrusion Production Line for Photovoltaic Cables

Technical Parameters

1. Equipment Purpose

This equipment is suitable for producing solar photovoltaic cables, low-smoke halogen-free cables, irradiated cables, and XL-PE cross-linked polyethylene cables; it is also applicable for conventional plastic extrusion such as PVC and PE.

Main Specifications

● Cable Types Produced: Solar photovoltaic cables, low-smoke halogen-free cables, irradiated cables, XL-PE cross-linked polyethylene cables, etc.

● Extrusion Material: Low-smoke halogen-free irradiated material.

● Finished Wire Diameter: MAX Ф8mm.

● Design Line Speed: 0~250m/min (line speed depends on wire diameter).

● Extrusion Capacity: 380+200kg (die head open, flexible PVC).

● Center Height: 1000mm.

● Power Supply: 380V±10%, 50HZ, three-phase five-wire system.

● Operation Direction: Facing the operation - Left-hand machine (right pay-off → left take-up) □; Right-hand machine (left pay-off → right take-up) □.

● Machine Color: Overall exterior - Blue orange texture RAL5015 (color card provided by customer).

● Electric Cabinet Exterior: RAL7035 gray-white corrugated paint.

● Safety Color: Yellow (as shown in the image).

Composition of Single Set of Equipment

| No. | Equipment Name | Specification | Quantity | Function | Remarks |

|---|---|---|---|---|---|

| 1 | Double-head Swing Drum Pay-off Machine | Ф630 | 1 unit | Wire pay-off | - |

| 2 | Semi-enclosed Magnetic Powder Tensioner | CFBA-300 | 1 unit | Wire tension control | - |

| 3 | Straightening Table | ZZA-60 | 1 unit | Wire straightening | - |

| 4 | High-speed Extruder Main Machine | 70-26D | 1 unit | Wire extrusion | Infrared heating |

| 5 | Alignment-free Square Die Head | U14 | 1 unit | Extrusion molding | - |

| 6 | Dryer | 50KG | 1 unit | Material drying | - |

| 7 | Suction Feeder | 240KG/Hr | 1 unit | Automatic feeding | - |

| 8 | Control System A | JCKZA | 1 unit | Cable control | With boom |

| 9 | Movable Water Tank (Letter-type) | SCHD-2.5M | 1 unit | Wire cooling | - |

| 10 | Muffler Blowing Dryer Box | CGA-12 | 1 unit | Wire drying by blowing | - |

| 11 | Outer Diameter Measuring Instrument | 3020 | 1 unit | Wire diameter measurement | Cold end |

| 12 | Double-layer Fixed Water Tank | SCGDS-4M | 1 unit | Wire cooling | - |

| 13 | Muffler Blowing Dryer Box | CGA-12 | 1 unit | Wire drying by blowing | - |

| 14 | 9m Horizontal Wire Storage Rack | CXSB-300 | 1 unit | Wire storage | - |

| 15 | Pneumatic Wire Clamp | SC40*40 | 1 unit | Wire clamping | - |

| 16 | Double-wheel Traction Machine | QYA-600 | 1 unit | Cable traction | - |

| 17 | Powder Coating Machine | GFJA | 1 unit | Cable powder coating | - |

| 18 | Straightening Table | ZZA-60 | 1 unit | Wire straightening | - |

| 19 | High-speed Extruder Main Machine | 90-26D | 1 unit | Wire extrusion | Infrared heating |

| 20 | Alignment-free Square Die Head | U14 | 1 unit | Extrusion molding | - |

| 21 | Dryer | 100KG | 1 unit | Material drying | - |

| 22 | Suction Feeder | 450KG/Hr | 1 unit | Automatic feeding | - |

| 23 | Control System B | JCKZA | 1 unit | Cable control | With boom |

| 24 | Movable Water Tank (Letter-type) | SCHD-2.5M | 1 unit | Wire cooling | - |

| 25 | Muffler Blowing Dryer Box | CGA-12 | 1 unit | Wire drying by blowing | - |

| 26 | Outer Diameter Measuring Instrument | 3020 | 1 unit | Wire diameter measurement | Cold end |

| 27 | Double-layer Fixed Water Tank | SCGDS-6M | 1 unit | Wire cooling | - |

| 28 | Muffler Blowing Dryer Box | CGA-12 | 1 unit | Wire drying by blowing | - |

| 29 | 12m Horizontal Wire Storage Rack | CXSA-300 | 1 unit | Wire storage | - |

| 30 | Pneumatic Wire Clamp | SC40*40 | 1 unit | Wire clamping | - |

| 31 | Electronic Length Counter | JMA-190.98 | 1 unit | Cable length measurement | - |

| 32 | Double-wheel Traction Machine | QYA-600 | 1 unit | Cable traction | - |

| 33 | High-speed Ink Printing Machine | YZ-100 | 1 unit | Cable printing | - |

| 34 | Power Frequency Spark Tester | 15KV | 1 unit | Voltage resistance test | - |

| 35 | Double-disk Shaftless Take-up Machine | 1000-1250 | 1 unit | Cable take-up | - |

| 36 | Waste Collection Box | 400400180 | 1 unit | Waste collection | - |

| 37 | Molding Die | Provided by customer | 1 set | Extrusion molding | - |

| 38 | Spare Tools | Professional tools | 1 set | Equipment accessories | - |

Equipment Introduction of Production Line Components

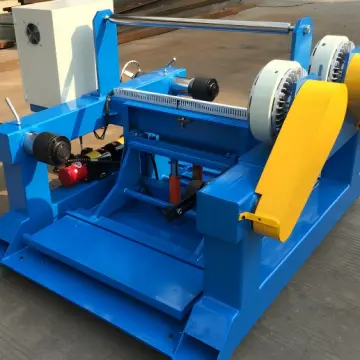

630 Double-head Swing Drum Pay-off Rack

● Suitable reel diameter: Ф630mm;

● Suitable wire diameter: Ф0.5-4.0mm;

● Maximum applicable line speed: 800m/min;

● Drive power: 400W geared motor;

● Motor power: 0.75KW motor;

● Mobile trolley with electric reel lifting;

● Frame made of stainless steel with double-layer sound insulation;

● Noise level during normal operation: ≤80dB (tested at 1.5m away);

● Two wire ends can be spliced to realize non-stop reel change;

● Suitable for high-speed continuous pay-off of extruders, no need to stop for reel change, and automatic stop when wire breaks;

● Tension control: Closed-loop tension control via displacement, adjustable tension.

Semi-enclosed Magnetic Powder Tensioner

Straightening Table

70-26D High-speed Extruder Main Machine

U14 Alignment-free Square Die Head

50KG Dryer

240KG Suction Feeder

Control System A - With Boom

2.5m Movable Water Tank (Letter-type)

Muffler Blowing Dryer Box

Outer Diameter Measuring Instrument

4m Double-layer Fixed Water Tank

9m Horizontal Wire Storage Rack

Pneumatic Wire Clamp

600 Double-wheel Traction Machine

Powder Coating Machine

Straightening Table

90-26D High-speed Extruder Main Machine

U14 Alignment-free Square Die Head

100KG Dryer

450KG Suction Feeder

Control System B - With Boom

2.5m Movable Water Tank (Letter-type)

Muffler Blowing Dryer Box

Outer Diameter Measuring Instrument

6m Double-layer Fixed Water Tank

12m Horizontal Wire Storage Rack

Pneumatic Wire Clamp

Electronic Length Counter

600 Double-wheel Traction Machine

Ink Printing Machine (Brand: Xinhua)

15kv Power Frequency Spark Tester

1000-1250 Double-disk Shaftless Take-up Machine

Waste Collection Box

Molding Die

Spare Tools

Main Accessory Brands

| No. | Accessory Name | Brand | Remarks |

|---|---|---|---|

| 1 | Programmable Logic Controller (PLC) | Siemens | - |

| 2 | Touch Screen | Weinview | - |

| 3 | Motor | Domestic Famous Brand | - |

| 4 | Drive | Domestic Famous Brand | - |

| 5 | Low-voltage Electrical Appliances | Chint/Schneider | - |

| 6 | Bearing | HRB/NTN/NSK | - |