01

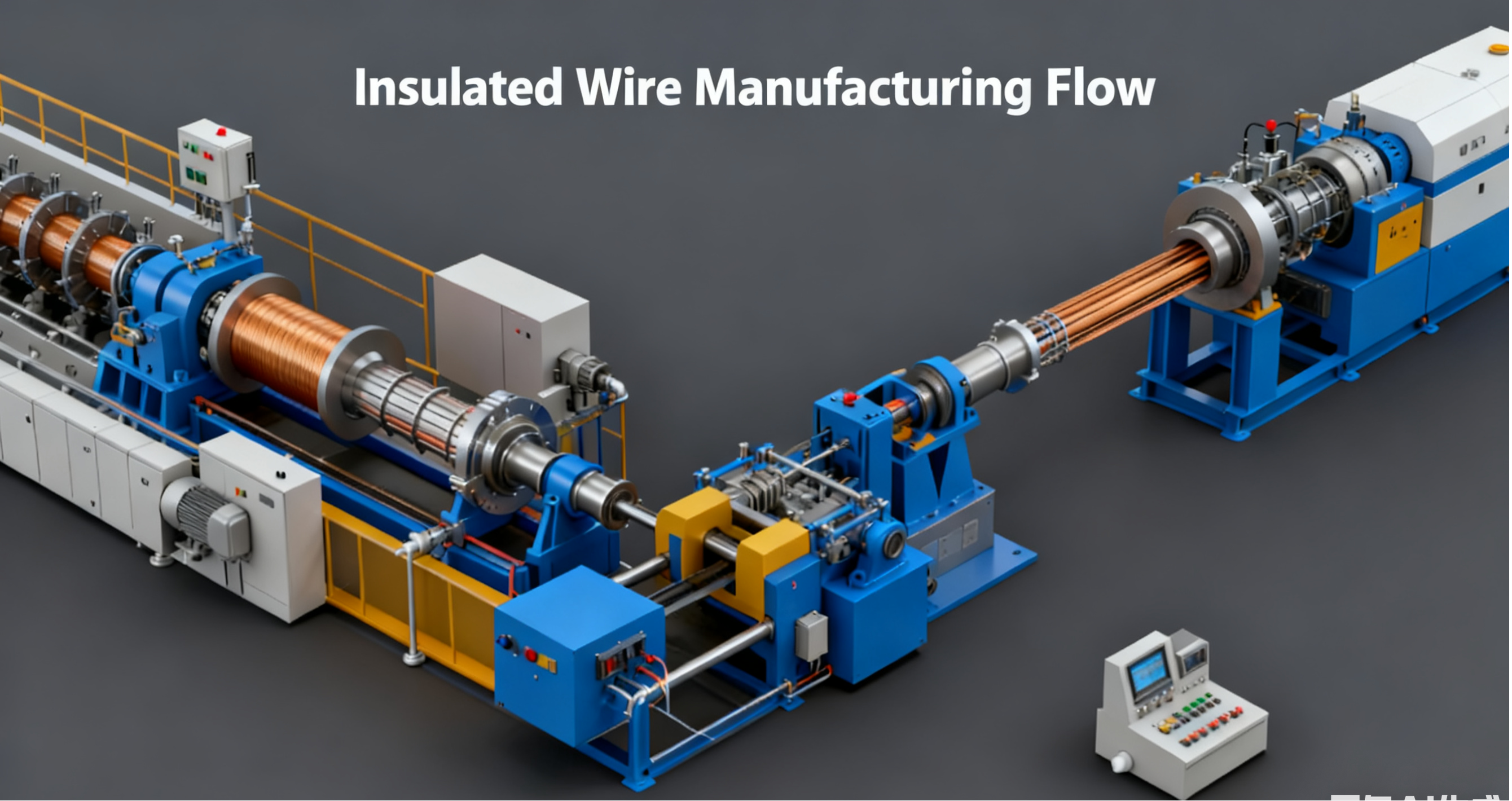

ÿ500 Torsion-free pair twisting machine

1. Application: Specially used for precision twisting of CAT5, CAT5E, LAN CABLE, CAT6, CAT7 high-performance unshielded twisted pair network cables.

2. Design principle: This machine adopts active pay-off. One strand is paid out from the outside. The wire enters from the main shaft A through the bow belt and then exits from the main shaft B. The wire passes through two main shaft guide wheels (i.e. two contacts), and the "skipping rope"principle is adopted. One twist and one retreat realizes 100% twist-free. The other strand is paid out from the internal cradle and directly exits from the main shaft B without twist. The two strands pass through the branch board at the outlet end of the main shaft B at the same time, and then pass through the external fixed eye mold to complete the twisting. In order to facilitate operation,transportation and installation, the design adopts the three-in-one pay-off, lead-in and take-up, which truly saves time, manpower and space in use. In order to reduce the trouble of changing wires and wiring, ÿ500mm wire reels are used from pay-off to take-up to completely avoid wire waste.

3. Equipment features: This machine has advanced design and scientific and reasonable structure. It has high speed, stable performance and precise pitch.High accuracy, balanced tension, round outer diameter, no strand jumping, low noise, easy operation, superior automatic protection function and other advantages that other similar machines cannot match.

Performance parameters

1. Wire drum specifications: ÿ500mm*ÿ56mm, outer width 300mm, inner width 250mm.

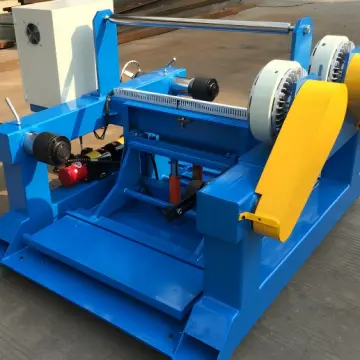

2. Tension for reeling and reeling: The motor speed is controlled by the swing lever and the counterweight is added to automatically adjust the tension of reeling and reeling, the tension is 10~3000g; the internal and external wire break protection is detected by mechanical contact, and the machine will automatically stop and alarm when the wire is broken, loose or empty.

3. Wire diameter: ÿ0.8mm~2.0mm.

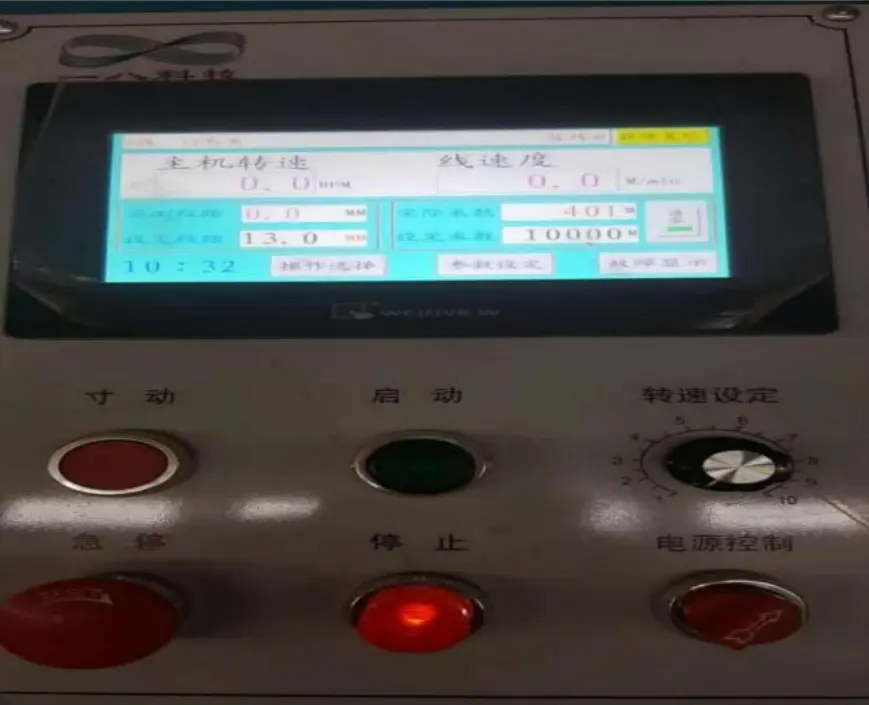

4. Twist pitch: 4~100mm, set on the touch screen.

5. Spindle brake: 10kg. m electromagnetic brake is used.

6. Motor power: Main machine:4kw AC motor + inverter control speed regulation.

Paying off and taking up: 0.37 kw AC motor + 1:7.5 reducer + inverter control speed regulation. Traction: 1 kw servo motor +controller.

7. Speed: Maximum speed 2000R/min.

8. Wire arrangement: ÿ20 barerod wire arrangement device (imitating German type) is adopted, and the width and spacing of the wire arrangement are precisely adjusted.

9. Twist direction: Forward or reverse twist is optional. 10. Lifting: 0.2kw 1:1600 reduction motor lifting, safe and convenient operation.

description2

Structural description

1. Machine body: High-quality steel plates are welded together and processed after long-term annealing, and will not deform after long-term use. All shaft holes and bearing seat mating surfaces are bored and milled at one time to ensure concentricity and verticality and improve the machine's operating performance.

2. Main structure: The spindle swivel adopts the latest technological achievements of our company. The spindle bearings are specially arranged and specially lubricated to reduce the friction temperature and noise of the bearings during operation, greatly improving the service life of the bearings. The swivel is strictly processed with high-speed precision dynamic balancing to ensure stable operation and meet the requirements of rapidly improving production efficiency.

3. Spindle material: 45# forged parts are selected, which are formed through a series of heat treatments and multiple processing. All mating parts a The keyways are hardened to prevent damage during assembly and disassembly and are durable.

4. Other shafts: All shaft fitting parts have been ground and surface hardened, which are wear-resistant and have a long service life.

5. Bearing seats: All bearing supports are processed strictly according to the allowable tolerance to improve equipment performance and ensure normal and stable operation.

6. Guide wheels: All guide wheels (wire wheels) have been surface polished and electroplated with hard chrome, which are smooth and durable. Avoid thread damage and ensure product quality.

7. Bearings: All are Japanese NSK or NTN genuine parts, using heated interference fit to ensure rotation Stable operation, improved service life and work efficiency.

8. Painting: glossy blue or as per customer's requirements.

9. Floorspace: 2920mm×1480mm×1450mm.

Automatic protection: The machine will automatically brake and stop or fail to start in any of the following situations:

1. The number ofmeters is reached;

2. The machine door is opened or not closed properly;

3. The internal or external wires are broken or the wire break detection is in a closed circuit state;

4. The lifting platform rises or does not fall into place;

5. The emergency stop button is pressed or the emergency stop button is not reset.

Gear Motor |

Chinese and Korean |

Host Motor |

brands: |

Servo Motor |

Dongzhou |

Inverter |

Siemens, |

PLC control system other |

Taiwan |

electrical appliances |

Delta, Shenzhen Sine, Taiwan Shilin, Chint or Japan Omron, etc. |

Computer control system

1. Hardware configuration:ÿ 7ÿ color touch screen workstation ÿ PLC programmable control system

2. Control process: ÿ Digital input automatic control process ÿ Dynamic simulation of production flow scene ÿ Real-time collection and display of various on-site processes and control parameters ÿ Quality control of the whole process ÿ Real-time fault detection and automatic alarm ÿ Expert knowledge system maintenance reference instructions ÿ Massive parameter storage performance (including group number, product name specification, pitch, brake tension, speed parameters, meters, number of shafts, number of faults and time, team messages, etc.) ÿ Online change and setting of process parameters